Clamping apparatus for shaft of parallel-connection type six-dimension force sensor

A technology of six-dimensional force sensor and fixture device, applied in the direction of measuring device, instrument, measuring force, etc., can solve the problems of incompatibility, complex structure, and insufficient contact area, and achieve good stability, simple operation, lateral little interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

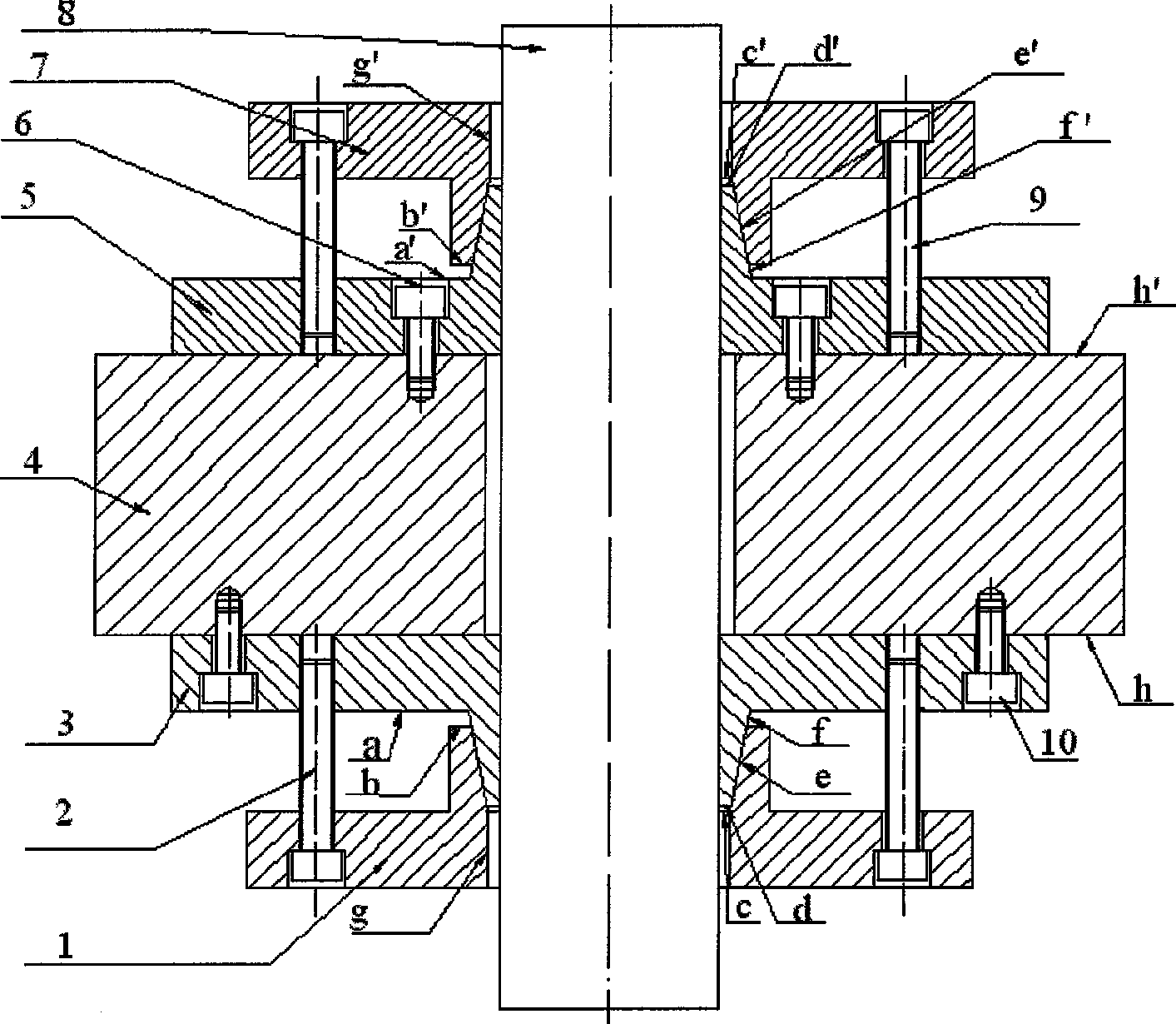

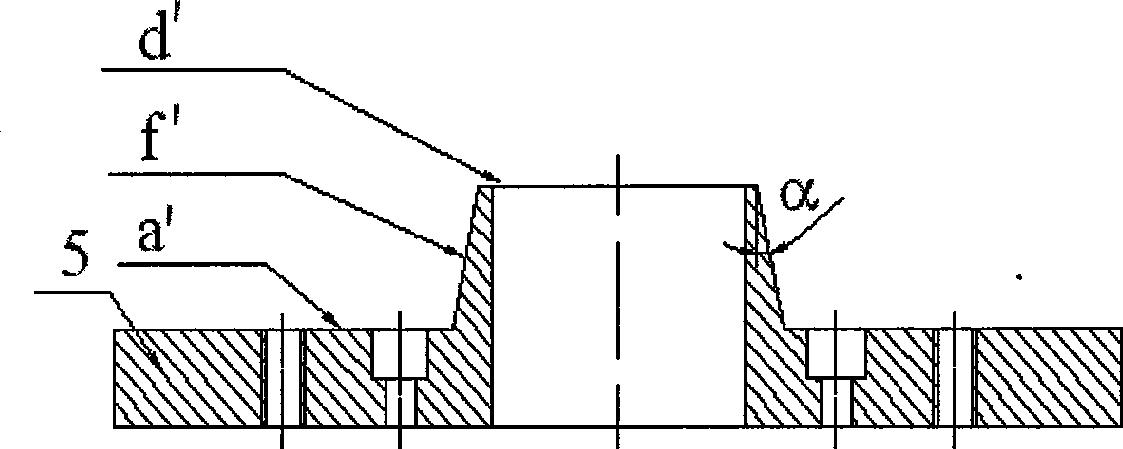

[0012] Describe in detail the implementation of the present invention in conjunction with accompanying drawing, as figure 1 As shown, install the lower outer clamp body 1 on the intermediate loading shaft 8, and ensure that the tapered surface is upward without fixing; install the lower inner clamping body 3 with two blocks of equal height, and install it on the intermediate loading shaft 8, with the tapered surface facing downward. , Attention should be paid to the installation height to ensure that other components can be installed smoothly. When installing the lower inner clamp body 3, a little lubricant should be added to its inner ring; then the piezoelectric quartz force sensor 4 is installed on the intermediate shaft, and its lower surface h is in contact with the upper surface of the lower inner clamp body 3. 8 evenly distributed lower short bolts 10 are pre-tightened, so that the lower inner clamp body 3 and the piezoelectric quartz force sensor 4 are connected togeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com