Motor internal stator and manufacturing method thereof

A manufacturing method and technology of inner stator, which are applied in the manufacture of motor generators, stator/rotor bodies, electrical components, etc., can solve the problems of torque pulsation, uneven permeability of permanent magnet air gap, difficult mechanization operation, etc. Avoid vibration and noise, improve material utilization, eliminate the effect of cogging torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

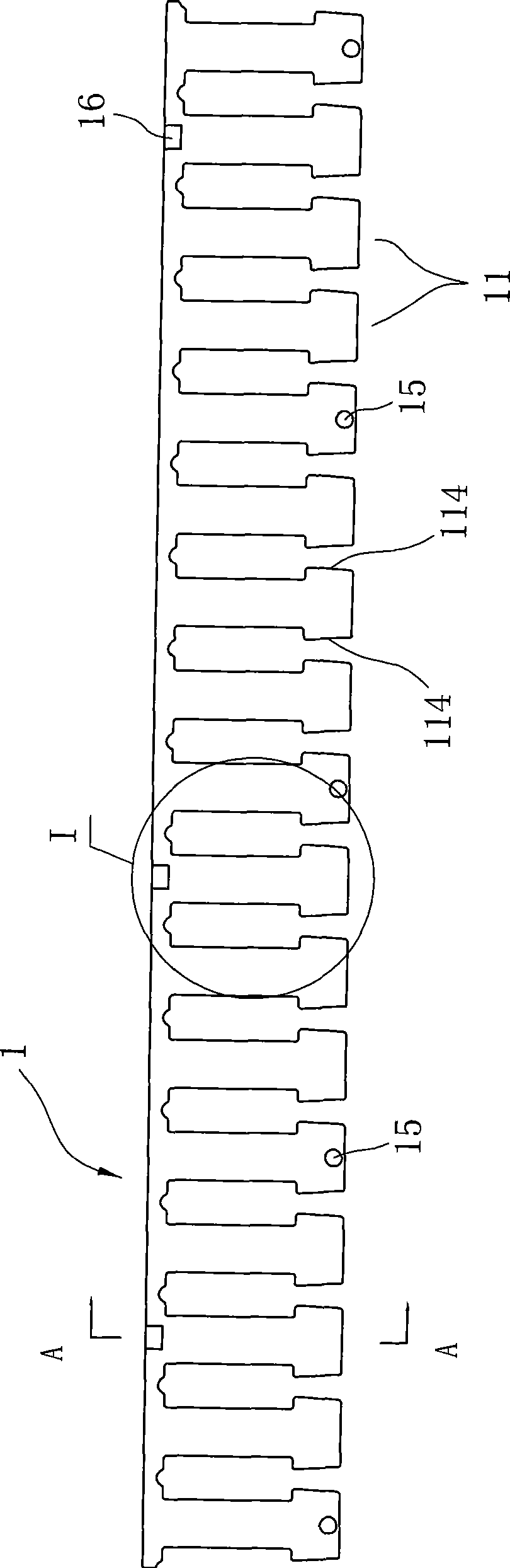

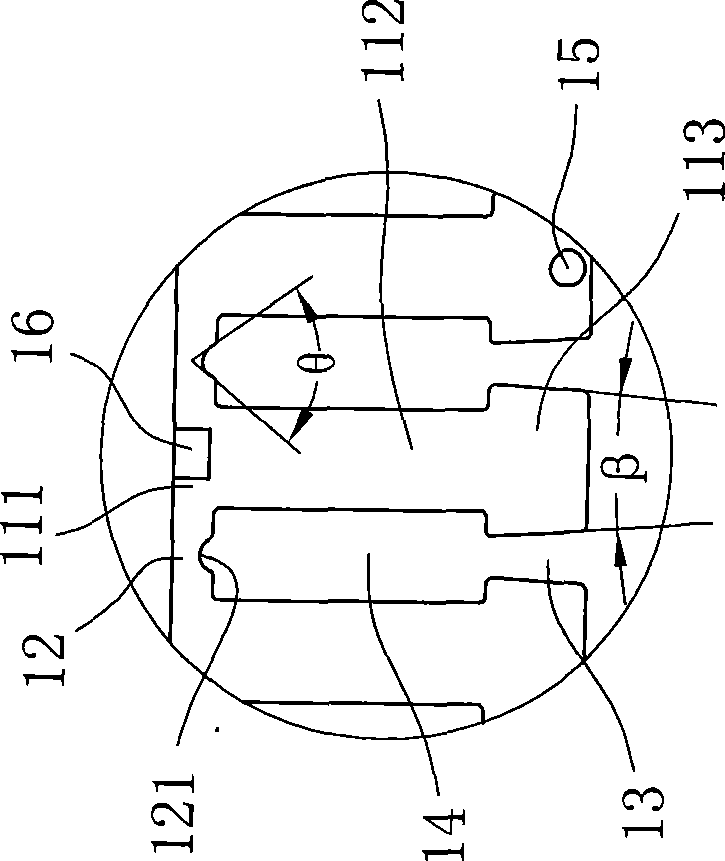

[0032] Such as Figure 1 ~ Figure 3 As shown, it is a schematic diagram of the structure of the in-line strip-shaped punches that make up the circular iron core of the present invention. The iron core is formed by winding and forming a plurality of strip-shaped punches 1 that are stamped and superimposed on each other. Each strip-shaped punch 1 includes There are multiple interconnected unit tooth blocks 11. In this embodiment, due to the large diameter of the inner stator, the formation of the iron core is not a strip-shaped punching piece that is wound and formed at one time, but is divided into three sections with the same unit Band-shaped punches 1 with the number of tooth blocks, each band-shaped punch 1 consists of 17 unit tooth blocks, two adjacent unit tooth blocks 11 are connected to each other by a connecting part 12 that can be bent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com