Sole for seesaw footwear

A rocker and shoe technology, applied in the field of shoe soles, can solve the problem of unbalanced movement of the toe, and achieve the effects of excellent wearing experience, enhanced shock absorption, and enhanced durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

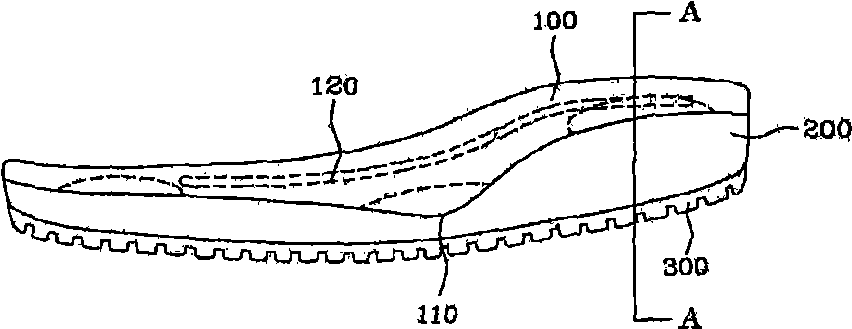

[0033] A first particular embodiment of the sole of a rocker sports shoe according to the invention has the figure 2 The structure shown in the schematic side view.

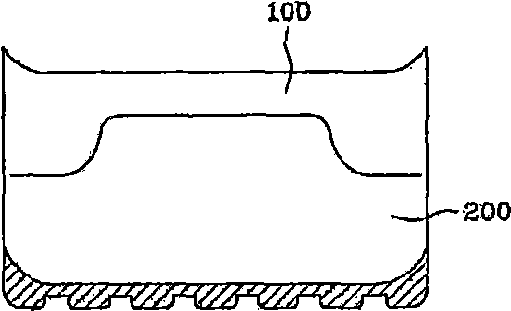

[0034] Such as figure 2 As shown, the main midsole 100, the secondary midsole 200, and the outsole 300 are sequentially coupled in this order from top to bottom, and the inside of the main midsole 100 may be provided with a plate-shaped shank 120 made of a highly elastic material. . For example, the shank 120 is preferably made of metal, non-ferrous metal or non-metallic material such as plastic material. The shank 120, when embedded in the main midsole 100, may help maintain the shape of the main midsole 100 while enhancing shock absorption.

[0035]The center of the lower side of the main midsole 100 protrudes downward in a convex manner relative to the rest of the lower side so as to serve as a walking axis 110 . The main midsole 100 may be tilted in the forward and rearward directions like a rocker base...

no. 2 example

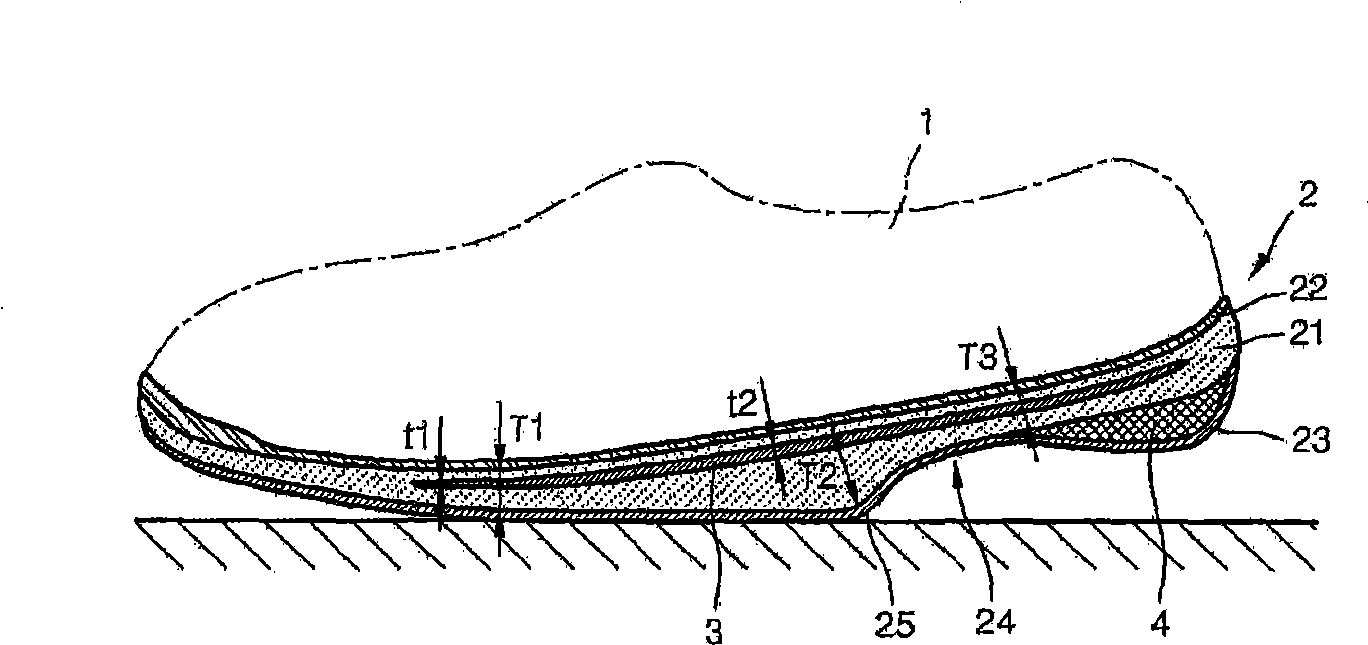

[0040] Next, a seesaw shoe according to a second embodiment of the present invention will be described below. see Figure 4 , which shows a schematic side view of a second embodiment, which is characterized in that the secondary midsole 200 has a polyol cloth 210 with a strong waterproof function attached to its outer surface.

[0041] Since the secondary midsole 200 is made of a softer material than the primary midsole 200, the secondary midsole 200 is susceptible to water damage. Therefore, when constructing the sub-midsole 200, it is preferable to attach the polyol cloth 210 to the outer surface of the sub-midsole 200 in order to maintain its original characteristics over a longer period of time. The polyol cloth may be selected from any of various known polyol cloths.

[0042] In the sole of rocker sports shoes according to the present invention, since the midsole is formed by coupling the secondary midsole 200 of softer material to the main midsole 100 of harder materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com