Planarity assessment method for decreasing number of measuring points

A technology for measuring the number of points and measuring the plane, applied in the field of flatness measurement, can solve the problems such as the impossibility of many flatness error measurement points, underestimation of the error value, etc., to achieve the effect of improving the measurement efficiency and increasing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with specific examples.

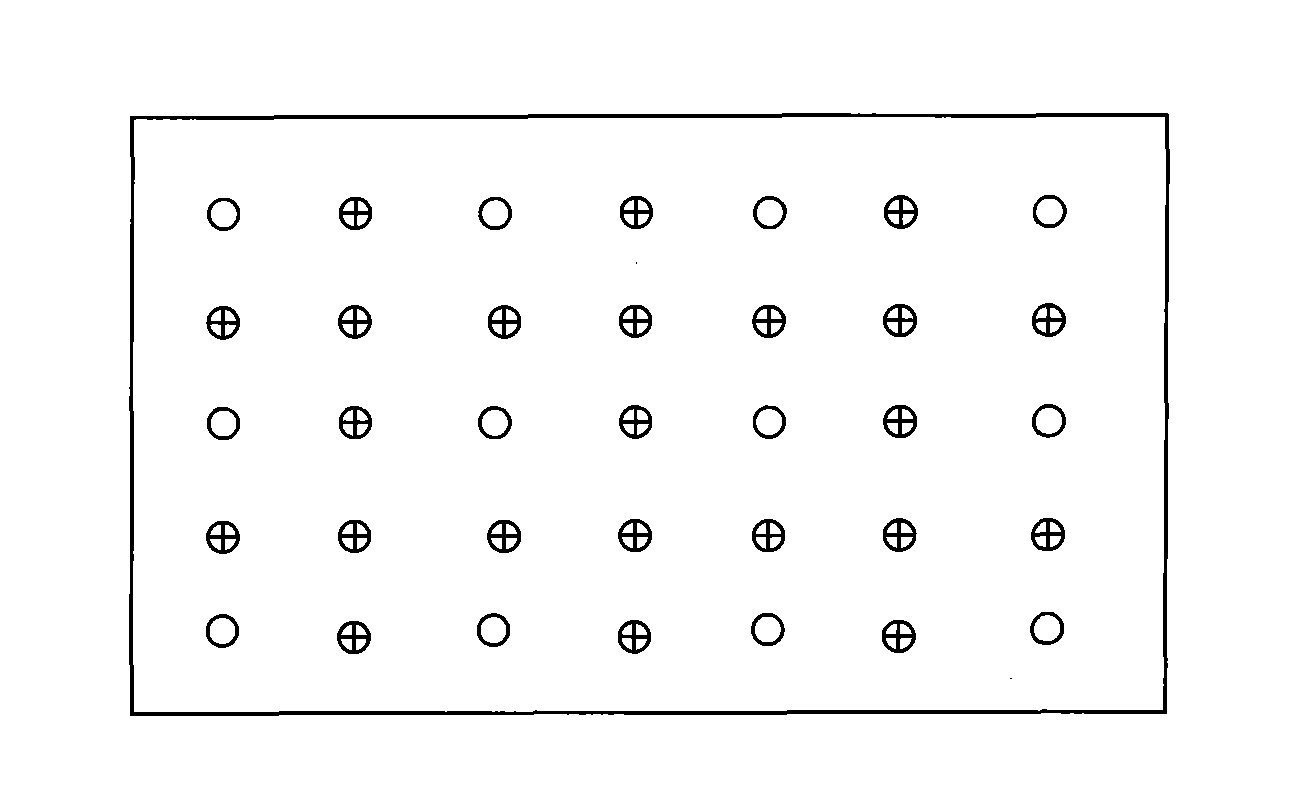

[0033] Assume that the measuring point distribution of a certain flatness error measurement is as follows: figure 1 as shown, figure 1 "○"indicates the actual measurement point, Indicates the measured point value estimated according to the maximum entropy method and the actual measured point (hereinafter referred to as the interpolation position). Based on these data, the evaluation and calculation of flatness error can be carried out. Since the flatness error is a random error, the flatness error obtained through the above estimated value will also be a random calculation result. In order to obtain accurate flatness error evaluation results, it is necessary to use the maximum entropy method to estimate the probability distribution of the measured plane error based on the limited information of actual measurement points, and to generate measurement estimates for each posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com