Spray tower structure for spraying and dedusting

A technology of dust removal tower and spray tower is applied in the field of spray tower structure for spray dust removal, which can solve the problems of high price, long dust removal pipeline and short service life, and achieve the effects of cheap price, rapid removal and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific drawings and embodiments.

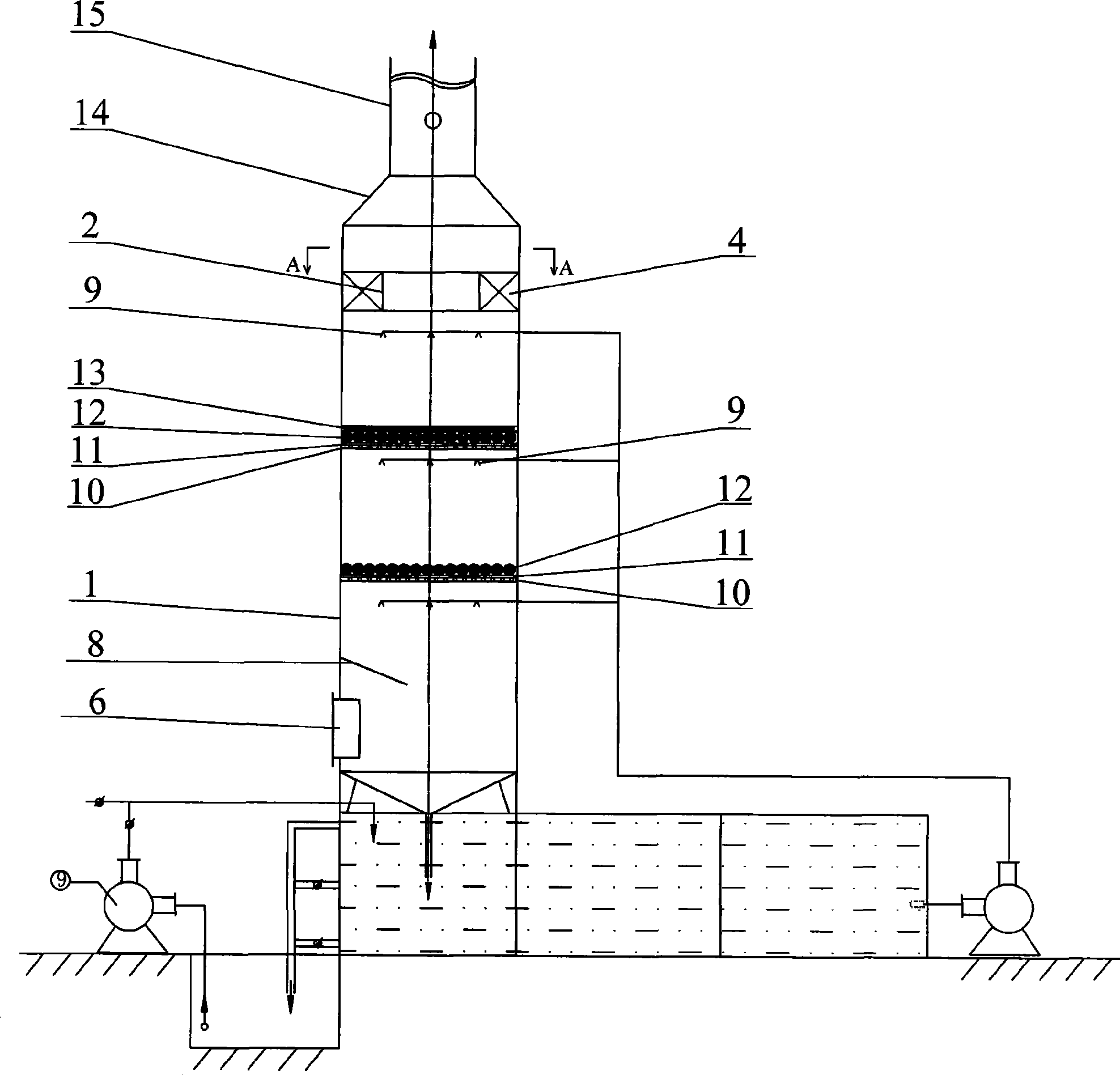

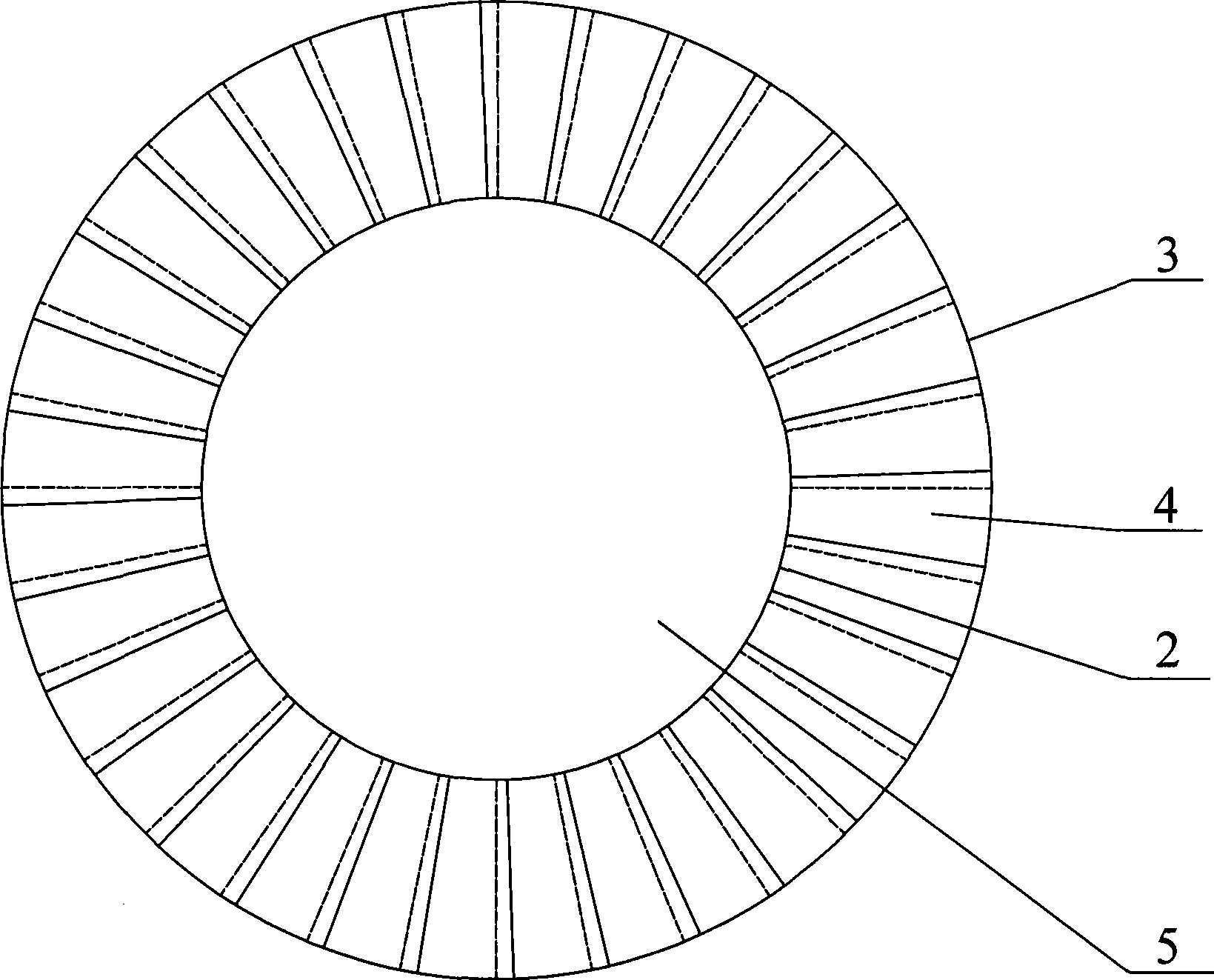

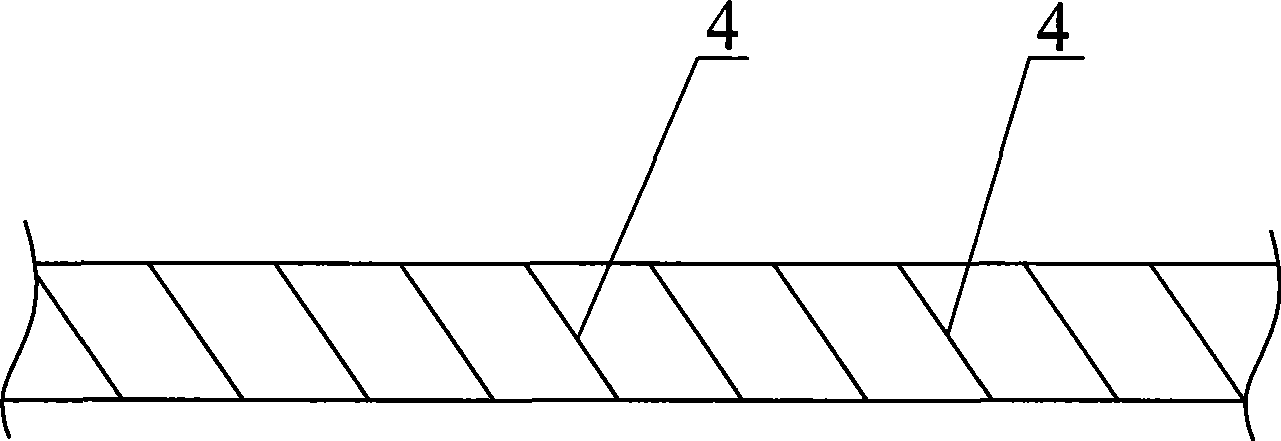

[0020] As shown in the figure: the spray tower structure for spray dust removal includes a first-level dust removal room, a second-level dust removal room and a third-level dust removal room arranged at intervals from bottom to top in the dust removal tower 1, above the third-level dust removal room The dedusting tower 1 is equipped with an airflow rotating device, the airflow rotating device includes an inner ring body 2 and an outer ring body 3 that are socketed together, and the outer wall of the inner ring body 2 and the inner wall of the outer ring body 3 are fixed There are blades 4, so that two adjacent blades 4, the inner ring body 2 and the outer ring body 3 form an air flow channel, and the length direction of the air flow channel intersects with the axis of the inner ring body 2 or the outer ring body 3 in different planes, and all air flow The passa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com