Pressurization type lance and use thereof in medicine spraying device of blood sampling tube assembly device

A technology for blood collection tubes and assembly machines, which is applied in the field of machinery, can solve the problems of high scrap volume, inaccurate test results, and tube body contamination in cell assays, and achieve the effects of avoiding health and safety problems, expanding the scope of use, and widening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

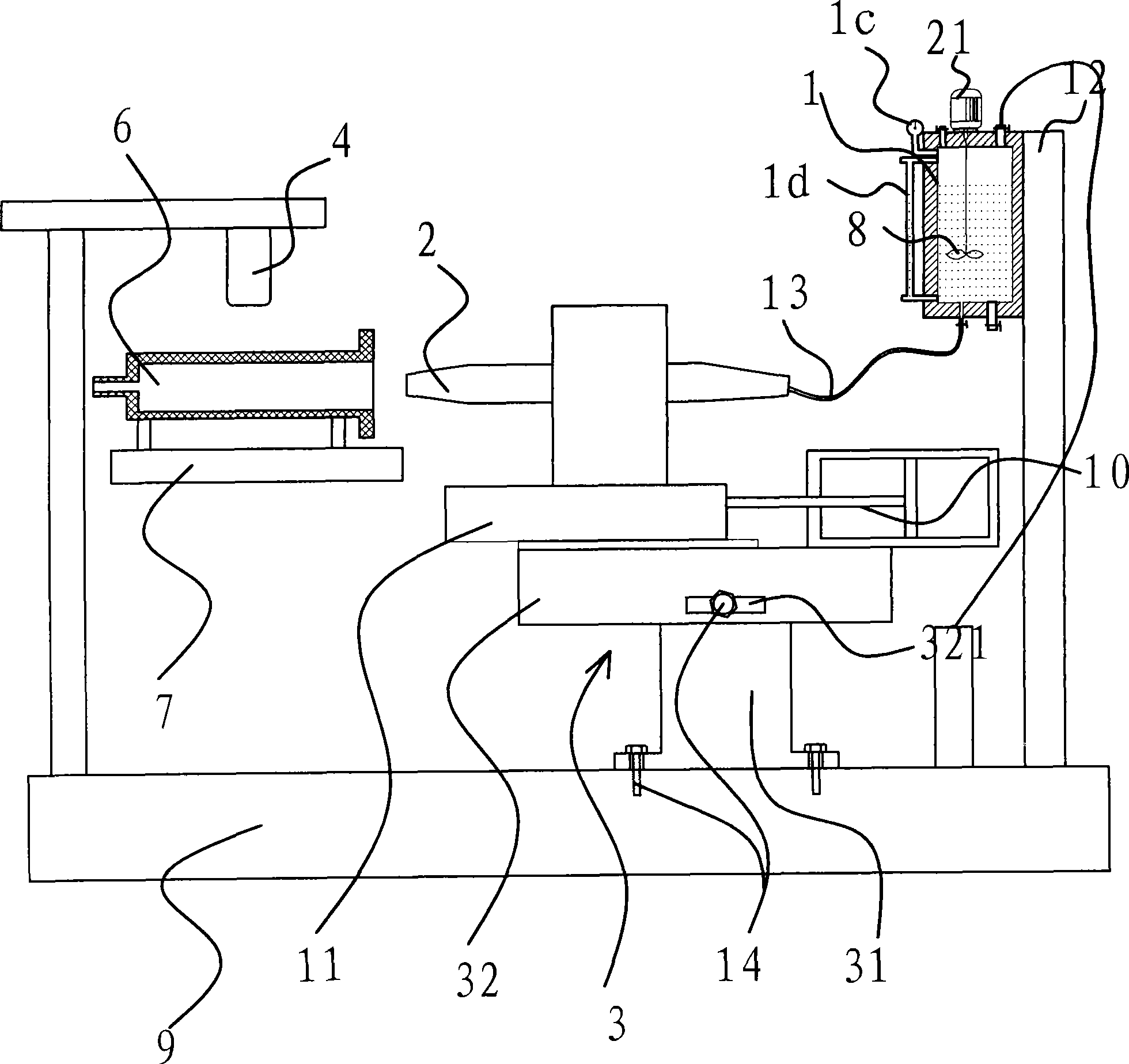

[0034] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

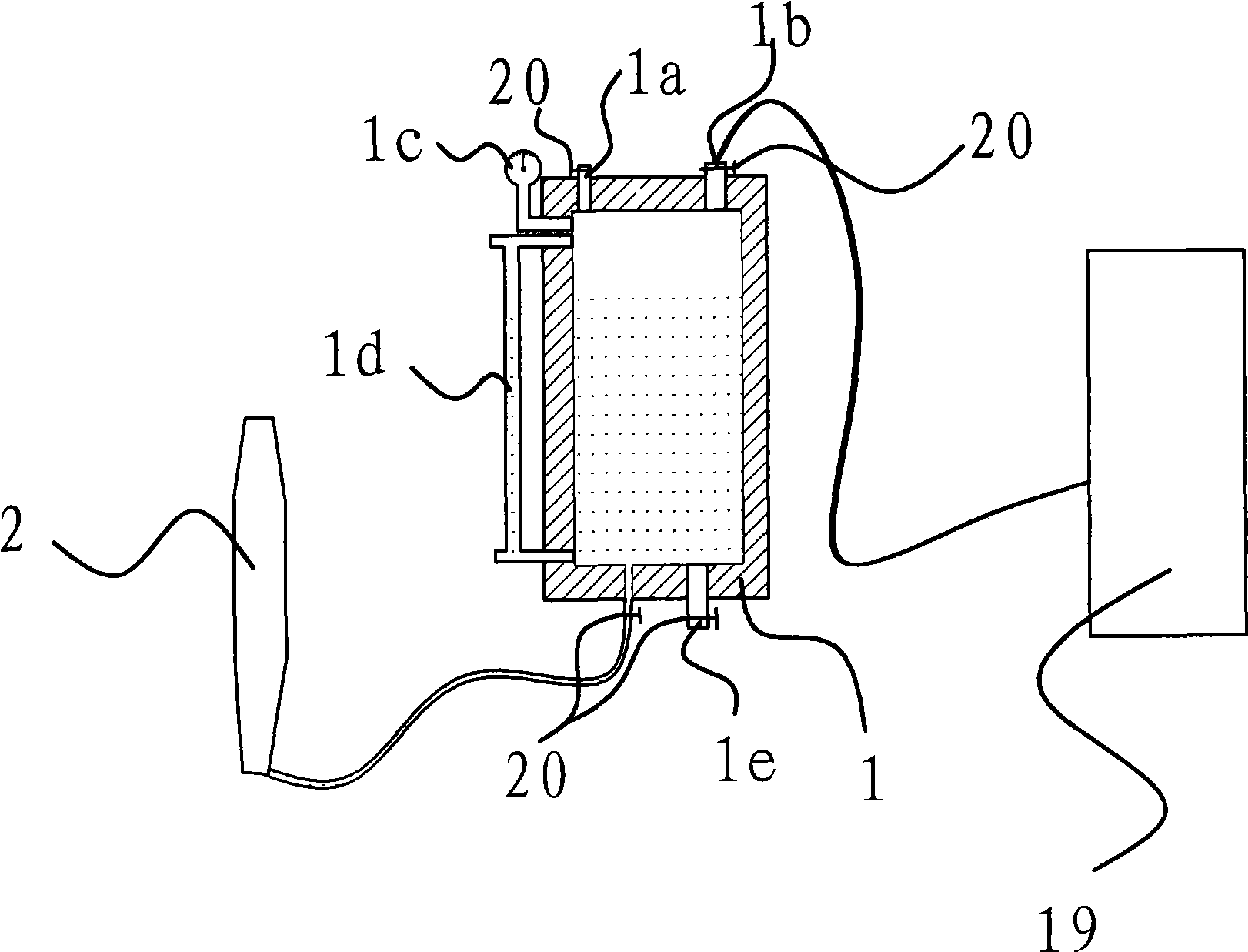

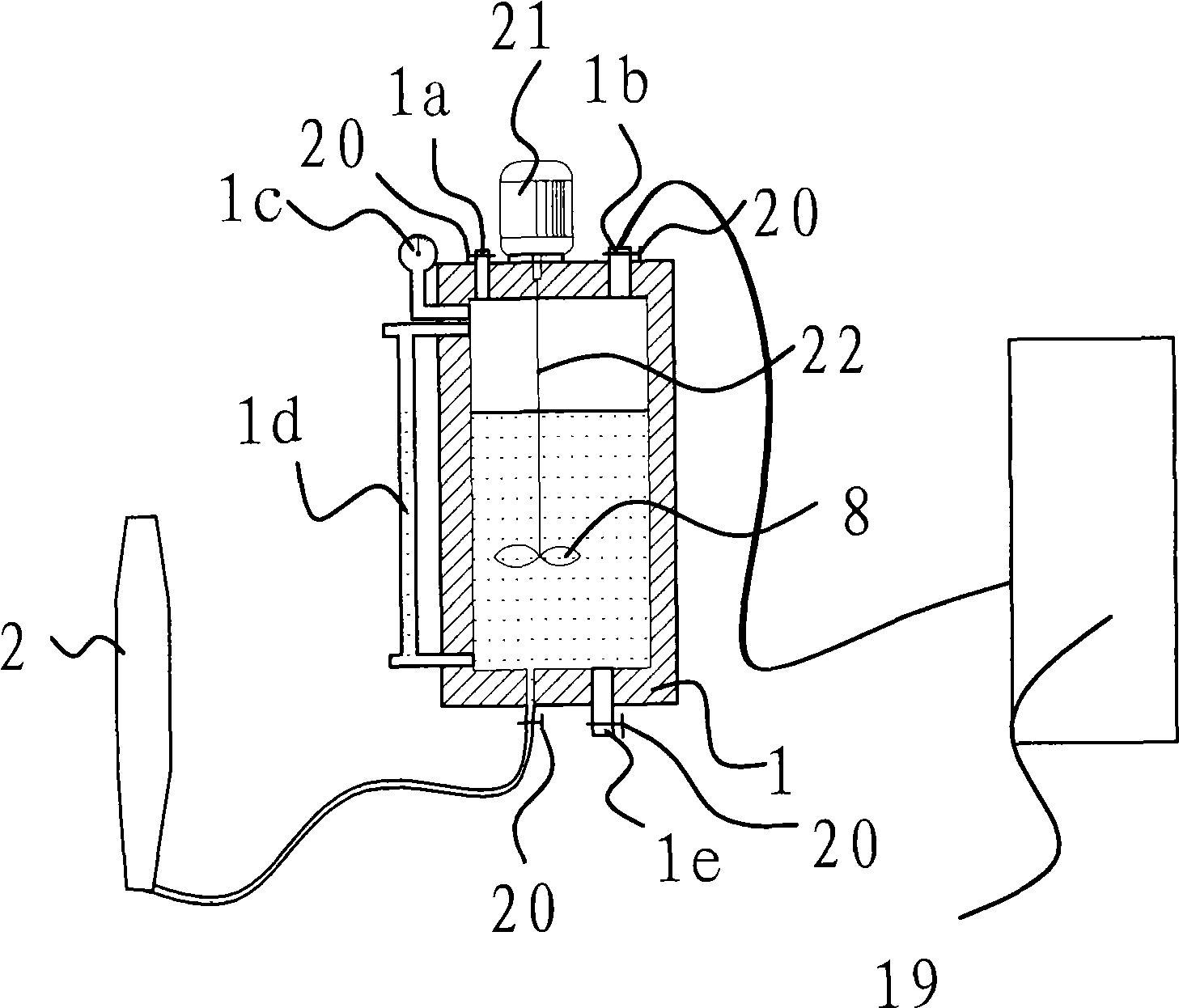

[0035] Such as figure 1 As shown, the pressurized spray gun device includes a liquid storage tank 1 for storing liquid medicine and a spray gun 2 connected with the liquid storage tank 1. The liquid storage tank 1 is a closed structure made of stainless steel. In the liquid storage tank 1 The upper part is provided with a fuel port 1a and an air inlet 1b connected with a pressure source 19. On the upper part of the liquid storage tank 1, a constant pressure is provided to keep the pressure in the liquid storage tank 1 greater than the pressure in the oil chamber of the spray gun 2 so that the pressure in the liquid storage tank 1 The liquid will automatically flow to the pressure setting mechanism of the spray gun 2 oil ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com