Printer paper-out detection device

A detection device and printer technology, applied in the direction of printing device, printing, etc., can solve the problems of print head and gear wear, jam, limited use range, etc., and achieve the effects of high reliability, accurate sensing and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in detail,

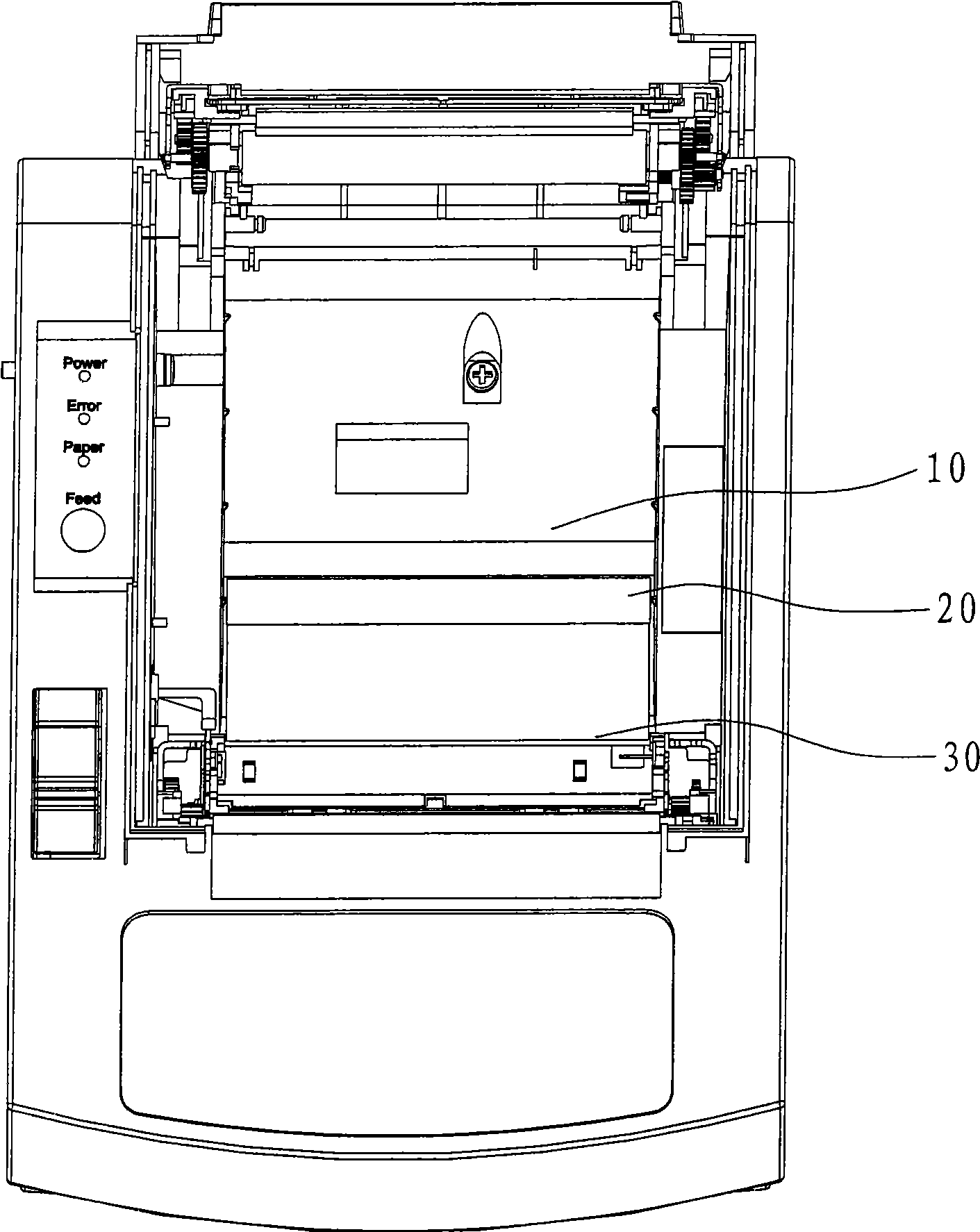

[0023] refer to image 3 As shown, a printer paper-out detection device of the present invention includes an infrared detection lamp 1 and an alarm circuit 2 .

[0024] The infrared detection lamp 1 includes a pair of emitting lamps 11 and receiving lamps 12, which are arranged obliquely in the accommodating cavity 3 of the printer body, and make the paper roll 4 enter the print head 5 between the emitting lamps 11 and the receiving lamps 12. between; in this embodiment, the transmitting lamp 11 and the receiving lamp 12 are respectively installed on the left bottom and the right top of the accommodating chamber 3, and are located at the diagonal position, and the infrared rays emitted by the transmitting lamp 11 It can be blocked by the paper, but cannot be received by the receiving lamp 12.

[0025] Alarm circuit 2 is connected with the warning ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com