Micro heating disk and manufacturing method thereof as well as micro heating disk system

A production method and micro-heating technology, applied in the field of sensors, can solve the problems of aging drift of the temperature sensing unit material, and achieve the effects of low cost, high precision, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

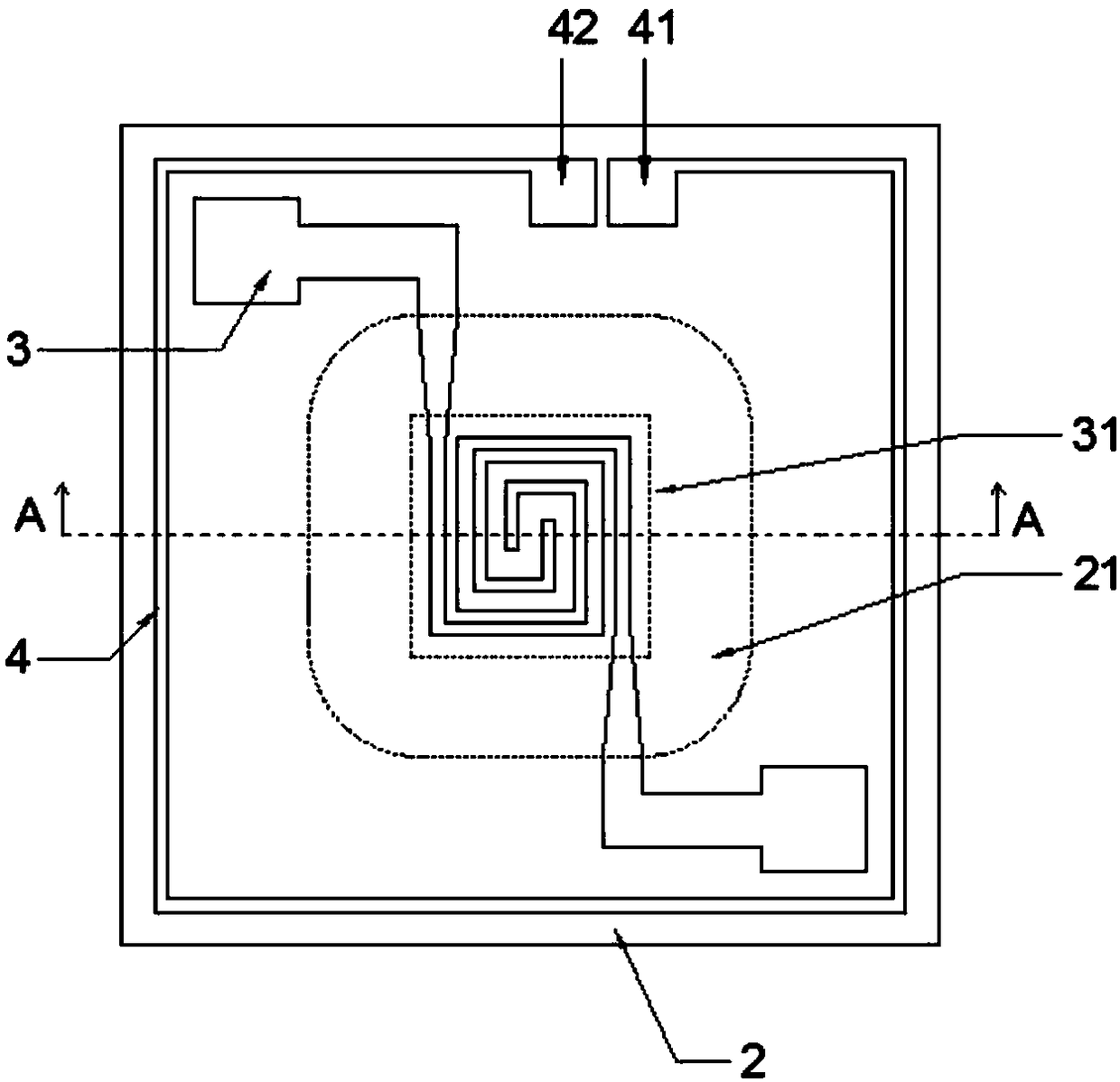

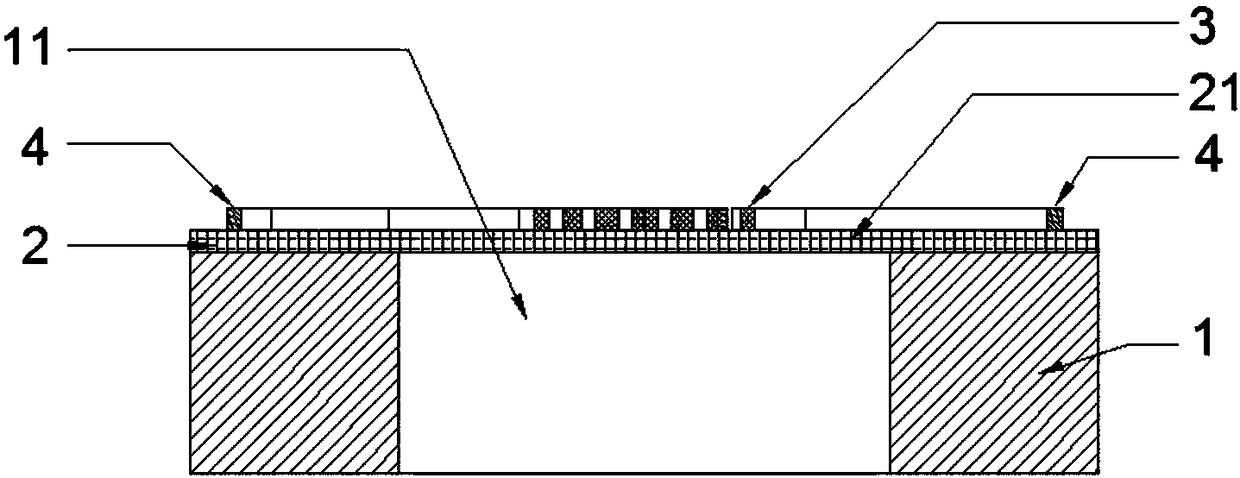

[0036] A micro hot plate, such as figure 1 with figure 2 As shown, it includes: a substrate 1, an insulating support layer 2 and a resistance heating layer 3 stacked sequentially from bottom to top, a temperature isolation cavity 11 is provided in the middle of the substrate 1, and the insulation support layer on the upper part of the temperature isolation cavity 11 2 is the temperature isolation suspension film 21, the resistance heating layer 3 is located on the insulating support layer 2 in a preset shape, the heating area 31 of the resistance heating layer 3 is located in the middle of the temperature isolation suspension film 21, and also includes a temperature sensing unit 4, the temperature sensor The measurement unit 4 is arranged around the substrate 1 (that is, the micro hot plate chip) in a ring shape.

[0037] By using the annular temperature sensing unit arranged around the substrate, the contact area between the temperature sensing unit and the environment is i...

Embodiment 2

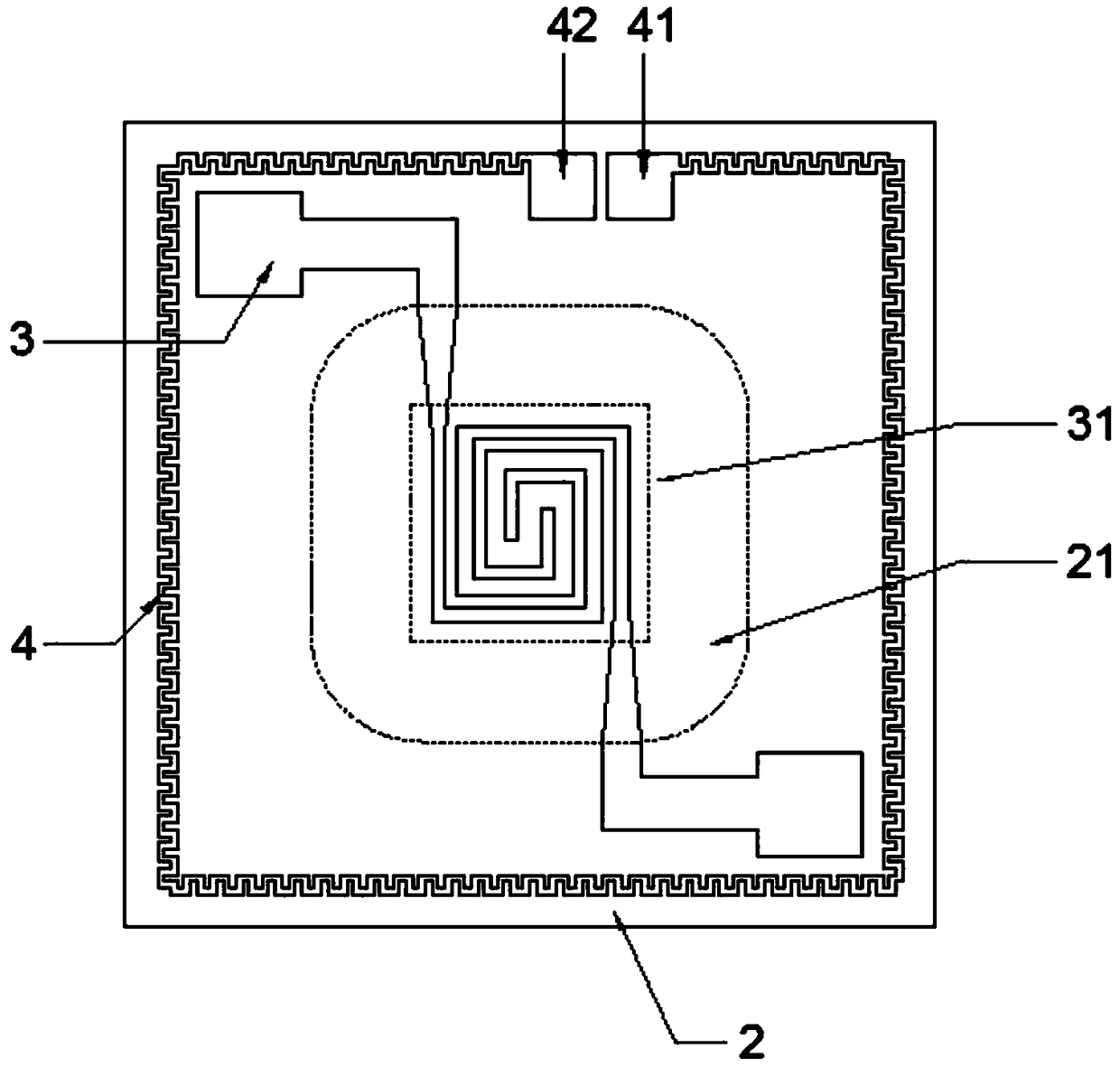

[0050] A micro hot plate, such as image 3 As shown, it includes: a substrate 1, an insulating support layer 2 and a resistance heating layer 3 stacked sequentially from bottom to top, a temperature isolation cavity 11 is provided in the middle of the substrate 1, and the insulation support layer on the upper part of the temperature isolation cavity 11 2 is the temperature isolation suspension film 21, the resistance heating layer 3 is located on the insulating support layer 2 in a preset shape, the heating area 31 of the resistance heating layer 3 is located in the middle of the temperature isolation suspension film 21, and also includes a temperature sensing unit 4, the temperature sensor The measurement unit 4 is arranged around the substrate 1 (that is, the micro hot plate chip) in a ring shape.

[0051] By adopting the annular temperature sensing unit arranged around the chip, the contact area between the temperature sensing unit and the environment is increased, and the ...

Embodiment 3

[0065] A micro hot plate, such as Figure 4 As shown, it includes: a substrate 1, an insulating support layer 2 and a resistance heating layer 3 stacked sequentially from bottom to top, a temperature isolation cavity 11 is provided in the middle of the substrate 1, and the insulation support layer on the upper part of the temperature isolation cavity 11 2 is the temperature isolation suspension film 21, the resistance heating layer 3 is located on the insulating support layer 2 in a preset shape, the heating area 31 of the resistance heating layer 3 is located in the middle of the temperature isolation suspension film 21, and also includes a temperature sensing unit 4, the temperature sensor The measurement unit 4 is arranged around the substrate 1 (that is, the micro hot plate chip) in a ring shape.

[0066] By adopting the annular temperature sensing unit arranged around the chip, the contact area between the temperature sensing unit and the environment is increased, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com