A liquid sensing apparatus for a liquid container for supplying a liquid to a liquid consuming apparatus, and a liquid container equipped with the liquid sensing apparatus

A liquid container, liquid sensing technology, used in liquid/fluid solid measurement, mechanical equipment, measurement devices, etc., can solve problems such as influence and wrinkling, and achieve the effect of preventing stop, small evaporation, and changing acoustic impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The details of the invention will be explained below with reference to the illustrated embodiment.

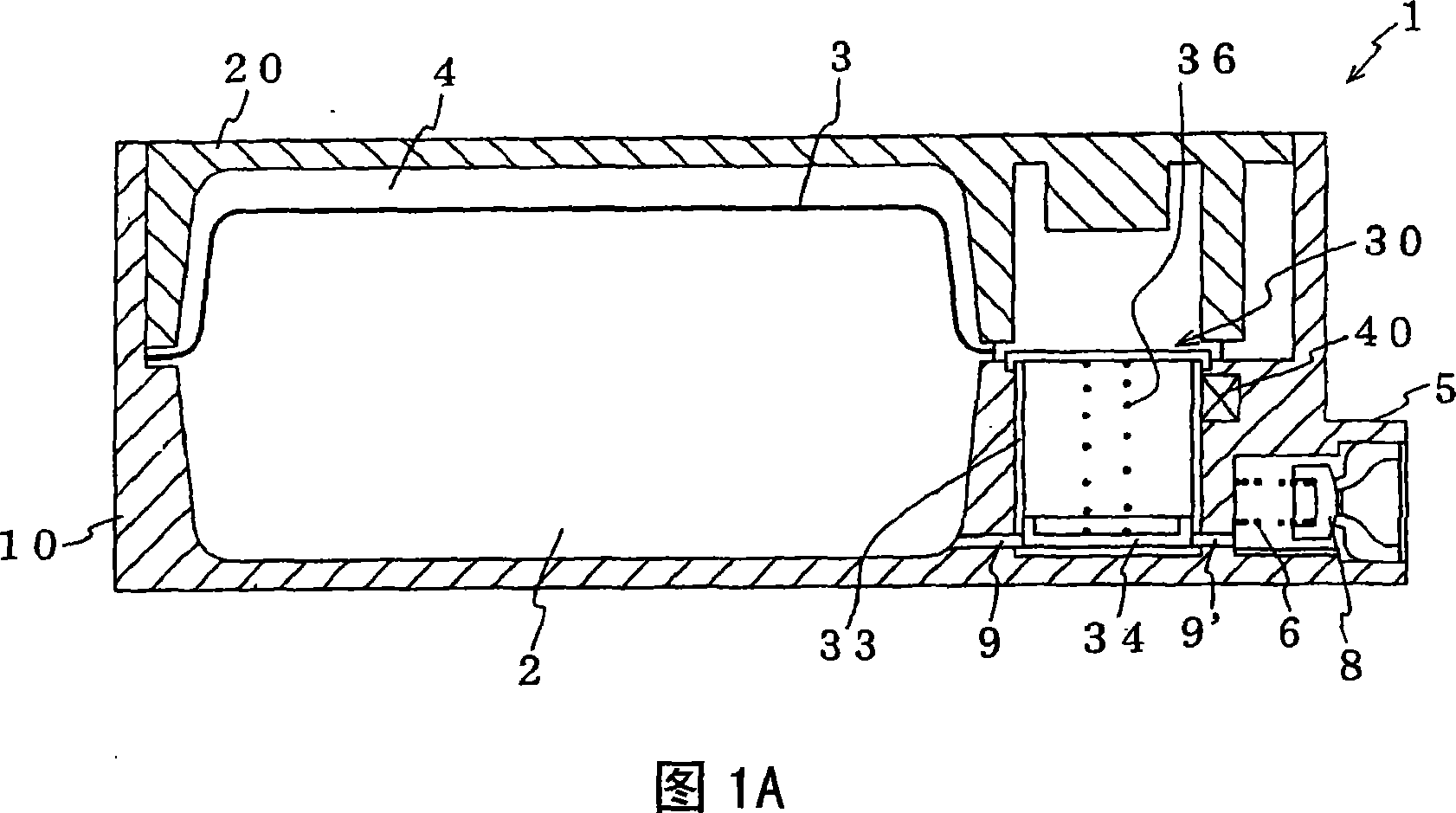

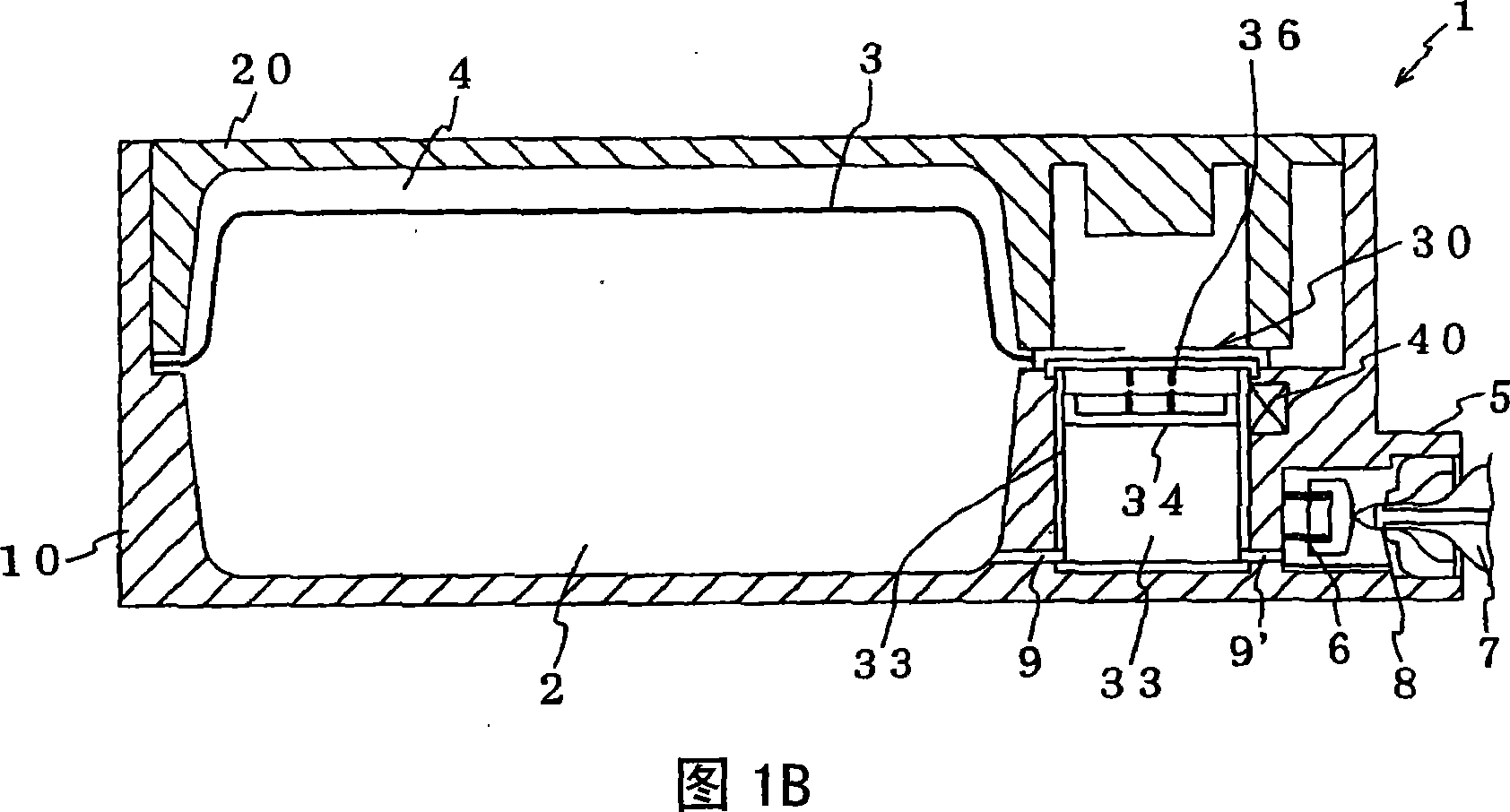

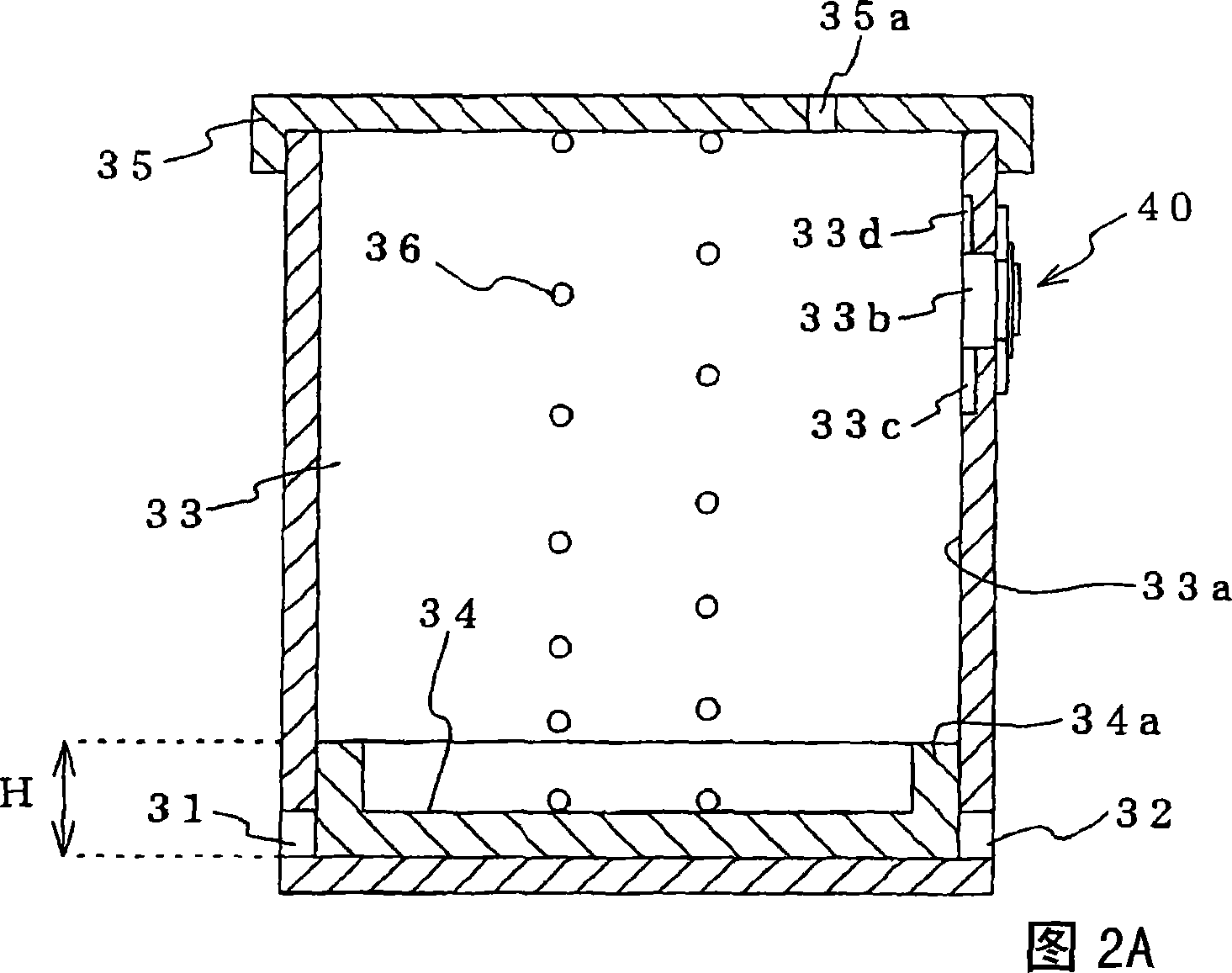

[0056] 1A and 1B are diagrams each showing an embodiment of the liquid container of the present invention by taking an ink cartridge containing ink to be supplied to an inkjet recording apparatus as a liquid consuming apparatus as an example.

[0057] In this embodiment, the first case 10 and the second case 20 each constituted by a cartridge member forming a half case are combined into a case to form the ink cartridge 1 serving as a liquid container. A flexible film member 3 formed of a resin film or the like is welded to the periphery of the first case 10 by heat welding or the like, and hermetically covers an opening portion formed in the first case 10 so as to form a container for containing ink such as ink. Liquid storage area 2 for liquids. And, the periphery of the second case 20 is in pressure contact with the thermally welded portion of the flexible film member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com