Composite grain diamond grinding wheel for UO2 pebble grinding device

A diamond grinding wheel and diamond technology, applied in bonded grinding wheels, abrasives, metal processing equipment, etc., can solve the problems of high recycling cost of grinding slag, affecting production costs and economic benefits, unstable pellet grinding quality, etc. , to achieve the effect of shortening the grinding process, saving equipment purchase funds, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

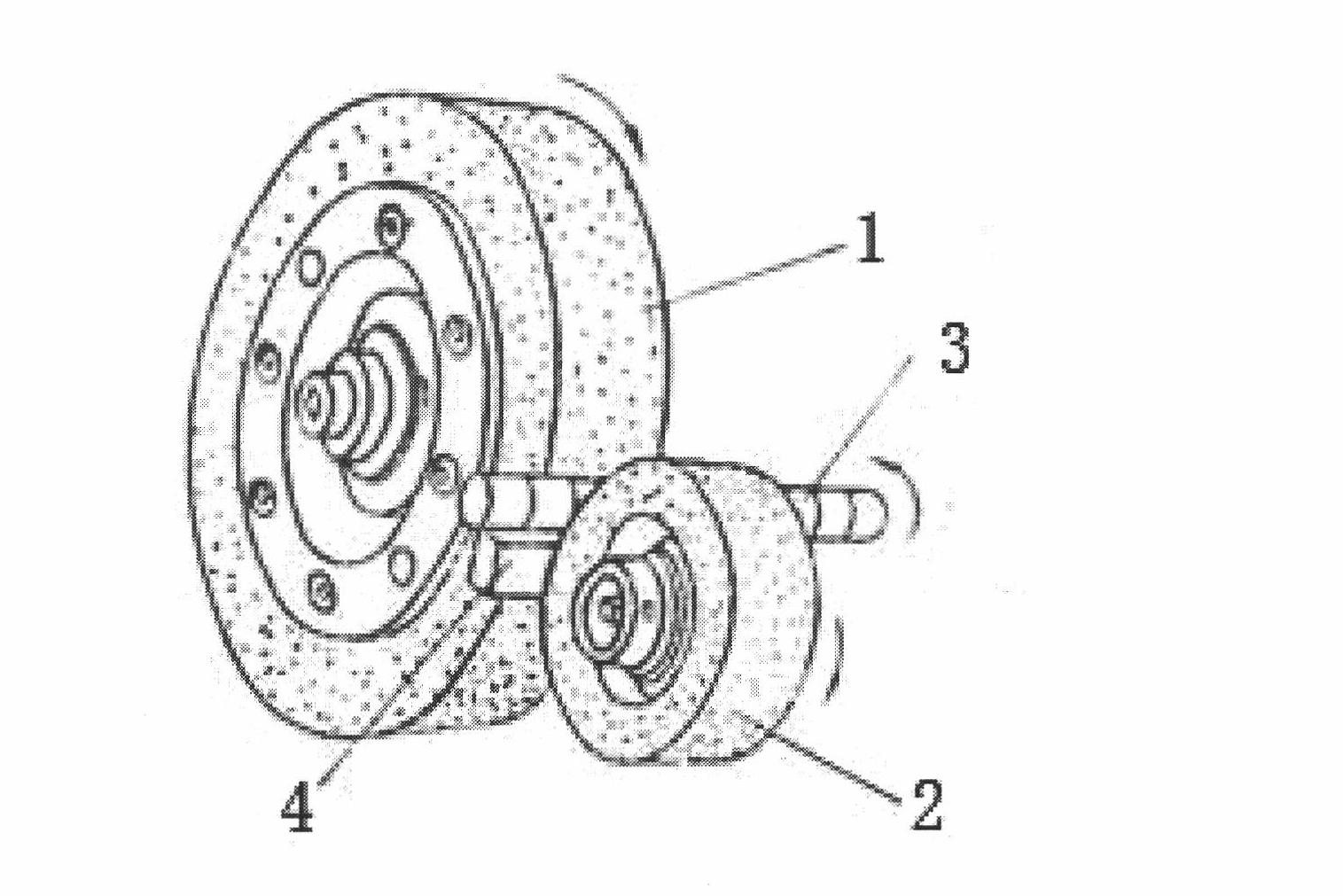

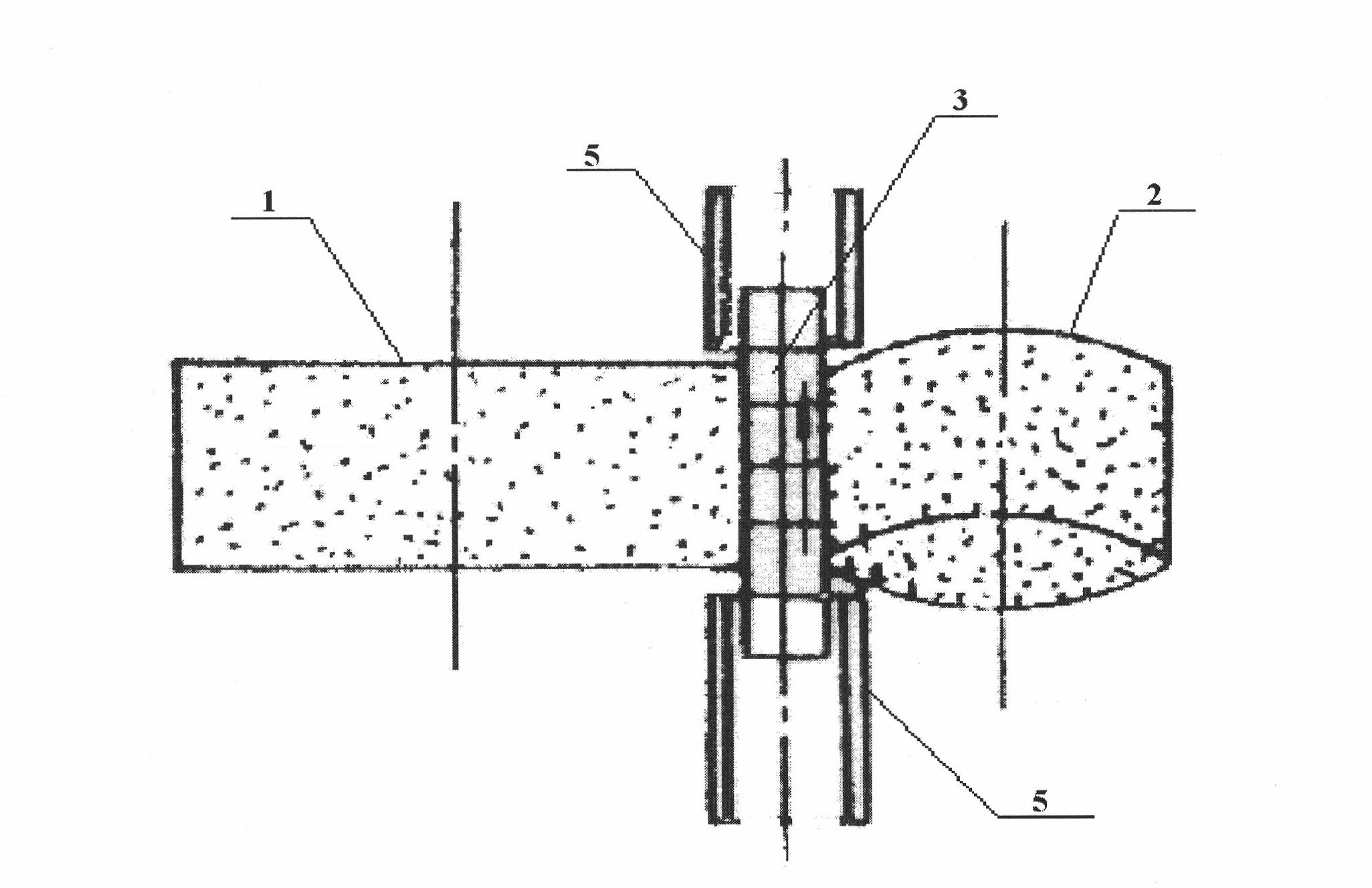

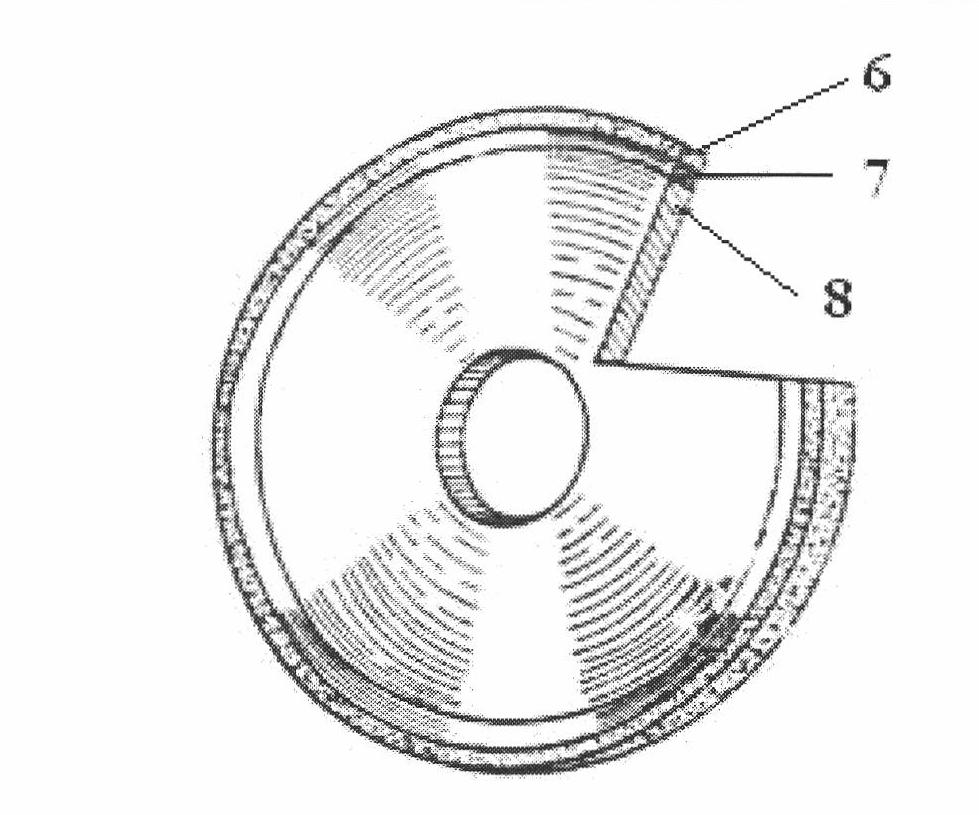

[0017] Such as image 3 and Figure 4 As shown, the UO of the present invention 2 The diamond grinding wheel with composite particle size for the pellet grinding device includes a grinding wheel base 8, and an adhesive layer 7 and a diamond layer 6 are sequentially arranged along the circumference of the grinding wheel base 8 from inside to outside. The diamond layer 6 is divided into a rough grinding zone I and a fine grinding zone II along the axial direction of the composite diamond grinding wheel according to the diamond grain size. The ratio of the length L1 of the rough grinding zone I to the length L2 of the fine grinding zone II is 1:2, the diamond grain size of the rough grinding zone I is 80 / 100, and the diamond grain size of the fine grinding zone II is 170 / 200. The diameter D of the outer circle of the composite particle size diamond grinding wheel is φ400mm, and the diameter of the inner hole is φ280mm. The adhesive layer 7 has a thickness of 2 mm; the diamond ...

Embodiment 2

[0022] It differs from Example 1 in that the ratio of the length L1 of the rough grinding zone I to the length L2 of the fine grinding zone II is 1:3, the diamond grain size of the rough grinding zone I is 100 / 120, and the diamond size of the fine grinding zone II is 1:3. The granularity is 200 / 230. The diameter D of the outer circle of the composite particle size diamond grinding wheel is φ500mm, and the diameter of the inner hole is φ290mm. The adhesive layer 7 has a thickness of 4 mm; the diamond layer 6 has a thickness of 5 mm. The axial length L of the composite particle size diamond grinding wheel is 240 mm, the length L1 of the rough grinding zone I of the diamond layer is 60 mm, and the length L2 of the fine grinding zone II is 180 mm. The diamond used in the diamond layer 6 is MBD type artificial diamond with a concentration of 100%.

Embodiment 3

[0024] It differs from Example 1 in that the ratio of the length L1 of the rough grinding zone I to the length L2 of the fine grinding zone II is 1:4, the diamond grain size of the rough grinding zone I is 140 / 170, and the diamond size of the fine grinding zone II is 1:4. The granularity is 230 / 270. The diameter D of the outer circle of the composite particle size diamond grinding wheel is 600mm, and the diameter of the inner hole is φ300mm. The adhesive layer 7 has a thickness of 6 mm; the diamond layer 6 has a thickness of 7 mm. The axial length L of the composite particle size diamond grinding wheel is 250 mm, the length L1 of the rough grinding zone I of the diamond layer is 50 mm, and the length L2 of the fine grinding zone II is 200 mm. The diamond used in the diamond layer 6 is MBD artificial diamond with a concentration of 120%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com