Rocking arm type die-sinking device

A rocker arm type, arm body technology, applied in the field of rocker arm type mold opening device, can solve the problems of unfavorable effective factory area effective utilization, occupation, large space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

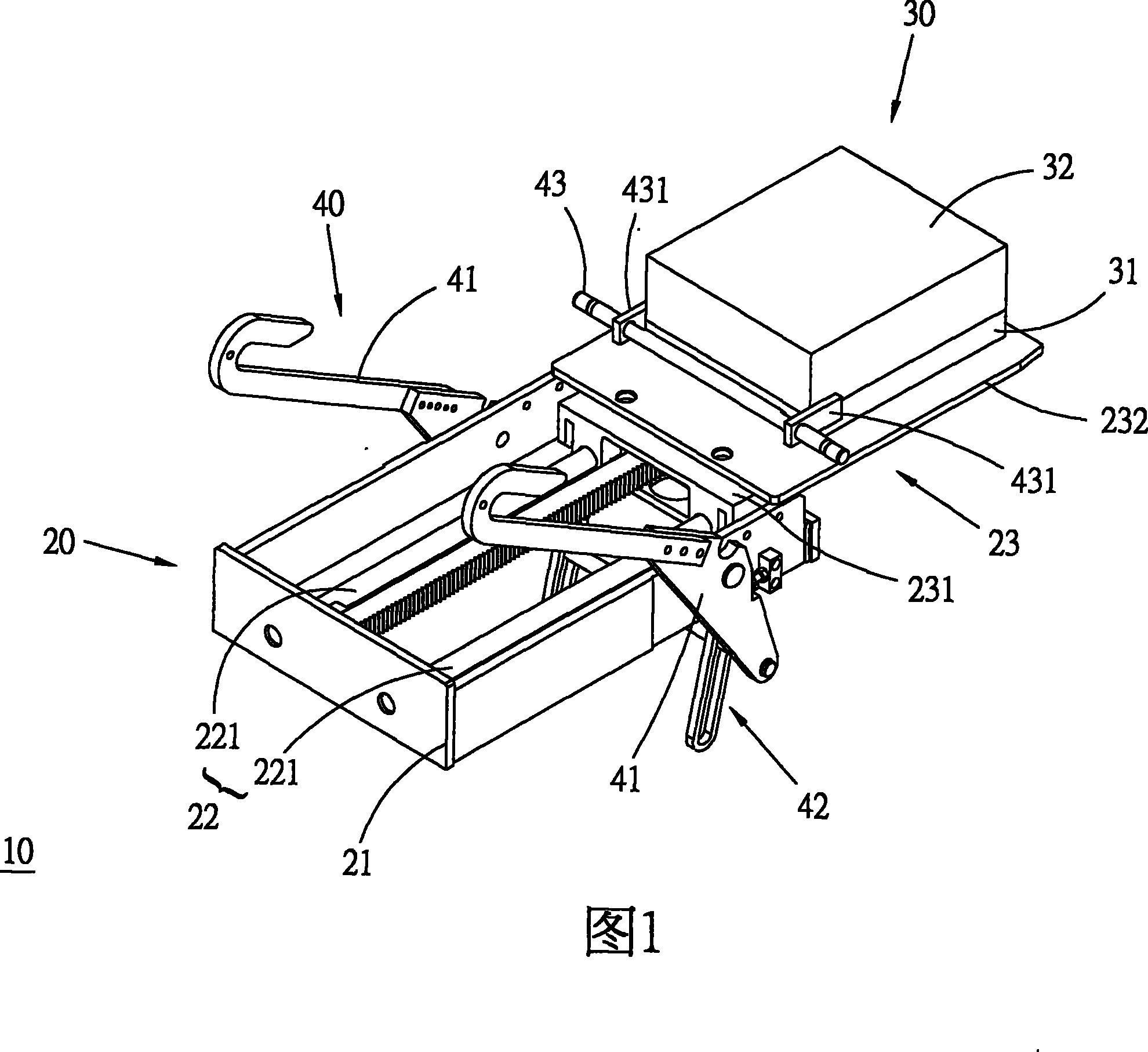

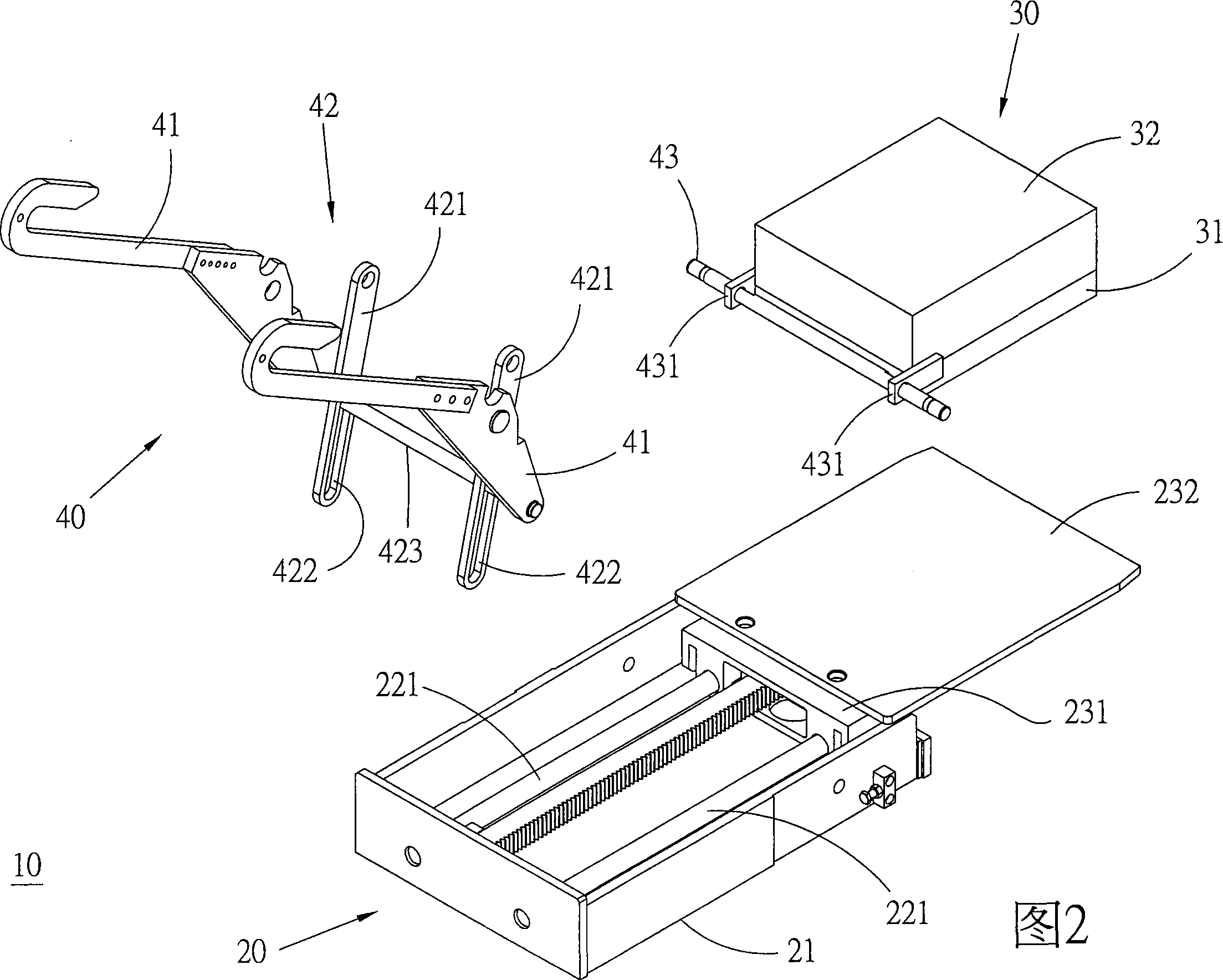

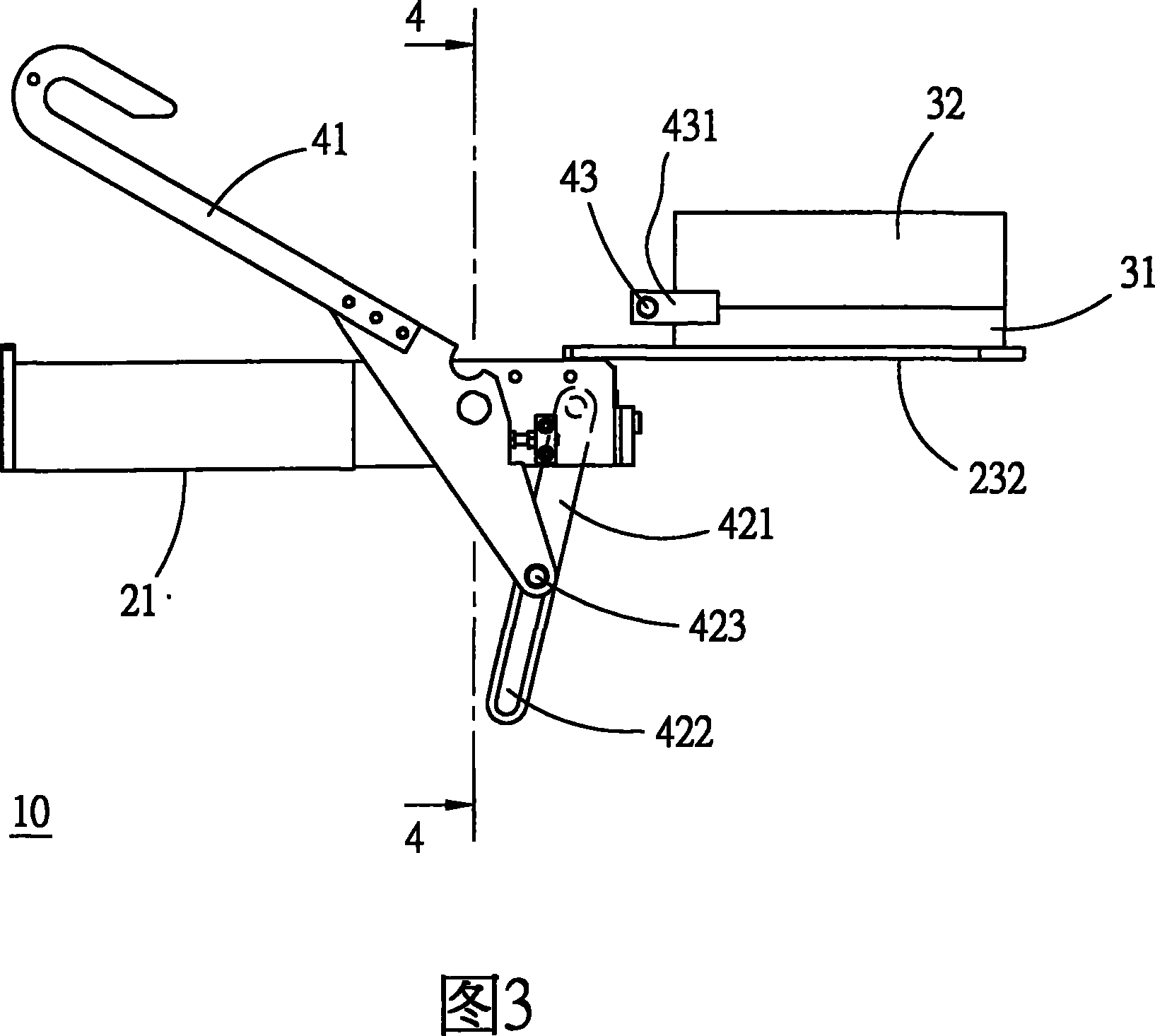

[0014] Please refer to the drawings, the swing arm type mold opening device 10 provided in a preferred embodiment of the present invention is mainly composed of a base 20 , a mold base set 30 and a rocker arm set 40 .

[0015] The base 20 has a rectangular frame-shaped seat body 21, a guide portion 22 composed of two guide rods 221 is parallel to the long axis of the seat body 21 and bridged between the inner facing frame surfaces of the seat body 21 with two ends, A moving part 23 is slidably arranged on the guide part 22, and can reciprocate and linearly displace between a seating position and a seating position along the rod axis direction of the guiding part 22; further, the moving part 23 has a moving block 231, threaded and slidably arranged on each of the guide rods 221, and a seat plate 232 is fixedly connected on the moving block 231 with one end.

[0016] The mold base group 30 has a bottom mold base 31 attached to the base plate 232, a movable mold base 32 is locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com