Washing machine capable of intelligently rinsing

A washing machine and functional technology, applied in the field of washing machines, can solve the problems of large measurement error of turbidity sensor turbidity detection range, insufficient rinsing times of fully automatic washing machines, waste of water and electricity for rinsing times, etc., to avoid waste, eliminate influence, and eliminate self-errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

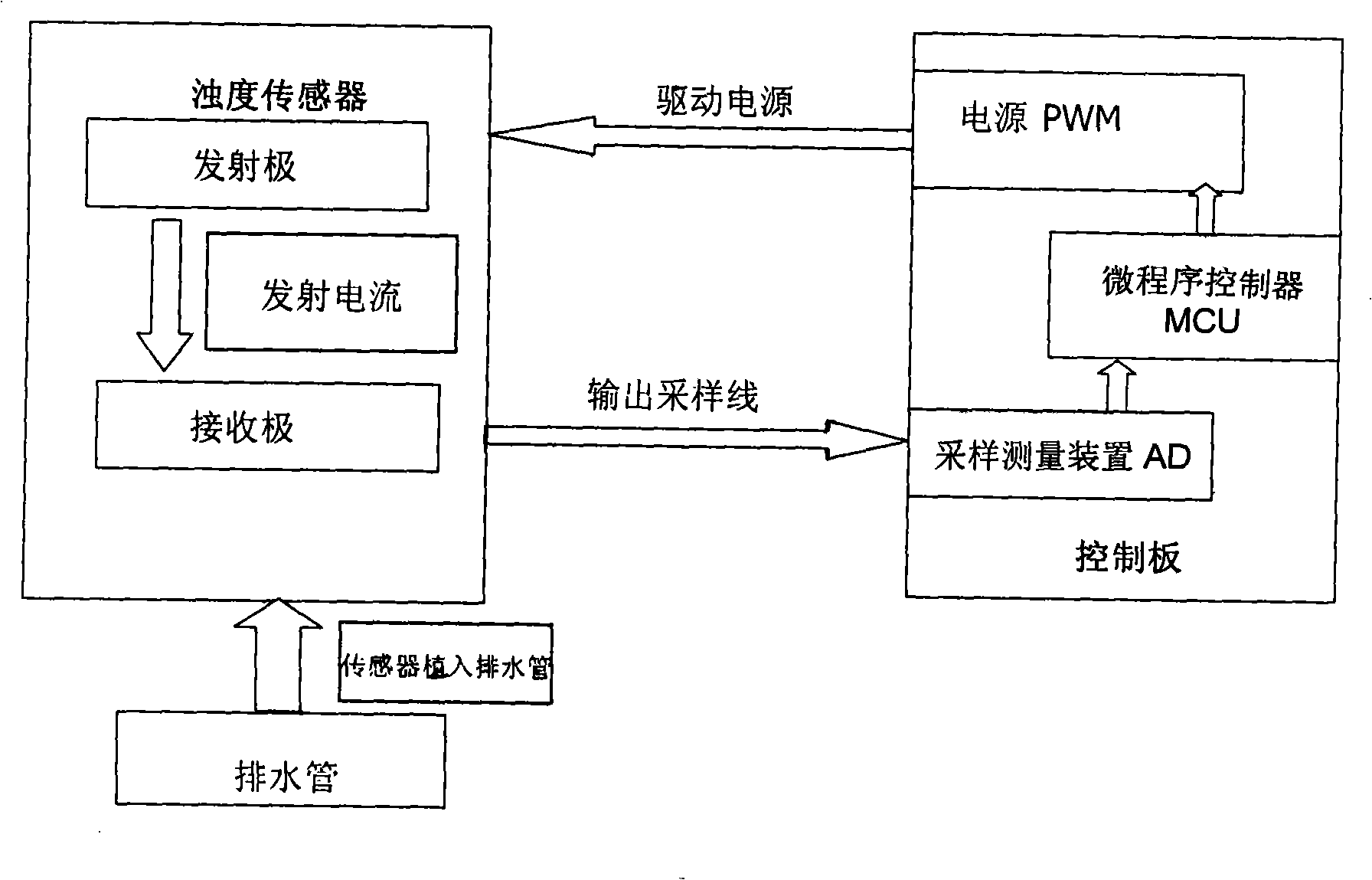

[0014] see figure 1 , the present invention is a washing machine with intelligent rinsing function, which is equipped with a turbidity sensor and a control panel, the turbidity sensor is implanted in the drain pipe, and the turbidity sensor detects the rinsing water in the dehydration state of the rinsing process when the motor rotates The resulting foam is tested.

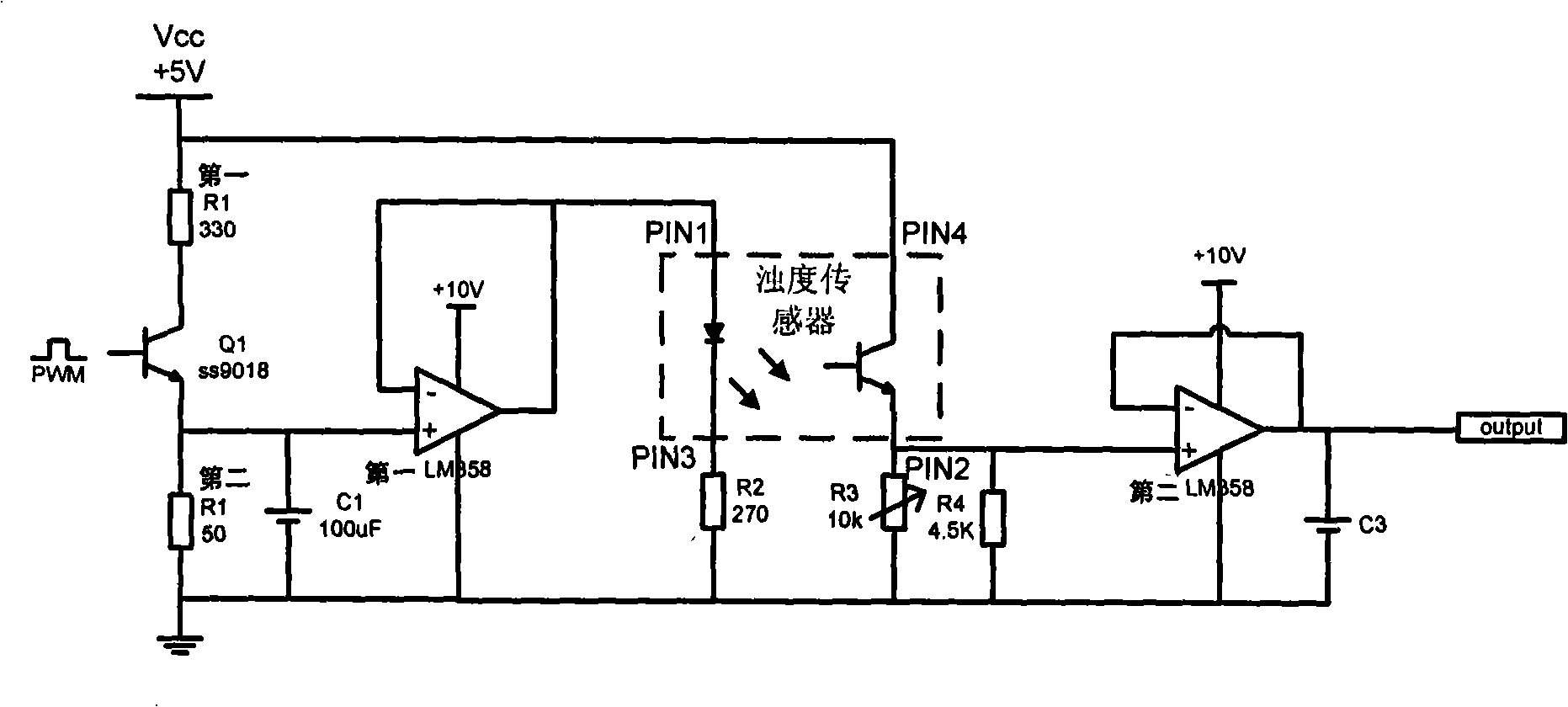

[0015] Connect the wiring terminal to the control board through the output sampling line. The turbidity sensor is driven by the PWM power supply, and the emitter of the turbidity sensor emits to the receiver.

[0016] The sampling and measuring device AD on the control board is connected with the microprogram controller MCU, and the microprogram controller MCU is connected with the power source PWM. The control circuit on the control board is connected with the turbidity sensor and connected with the microprogram controller MCU.

[0017] The drainpipe is bent to have a certain height, and the turbidity sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com