Floating chuck apparatus and floating chuck unit

A technology of floating chucks and chucks, which is applied in the direction of chucks, etc., can solve the problems of reduced productivity, difficulty in ensuring positioning accuracy, and tilting of the chuck axis, and achieve the effects of improving productivity, realizing positioning accuracy, and realizing compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

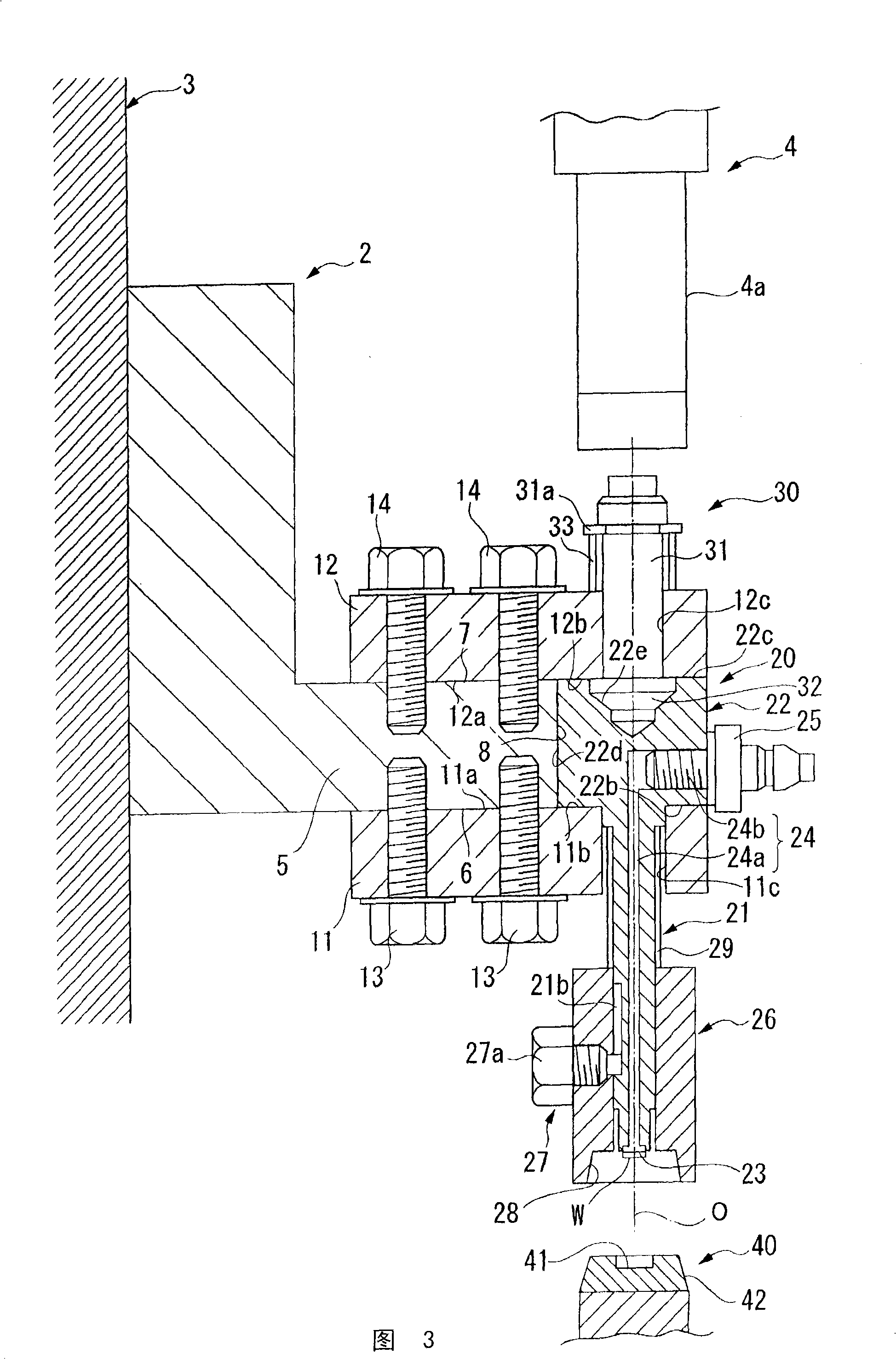

[0051] Hereinafter, embodiments of the present invention will be described with reference to the drawings. Here, an embodiment of the floating chuck device of the present invention will be described together with a floating chuck unit of the present invention incorporating the floating chuck device.

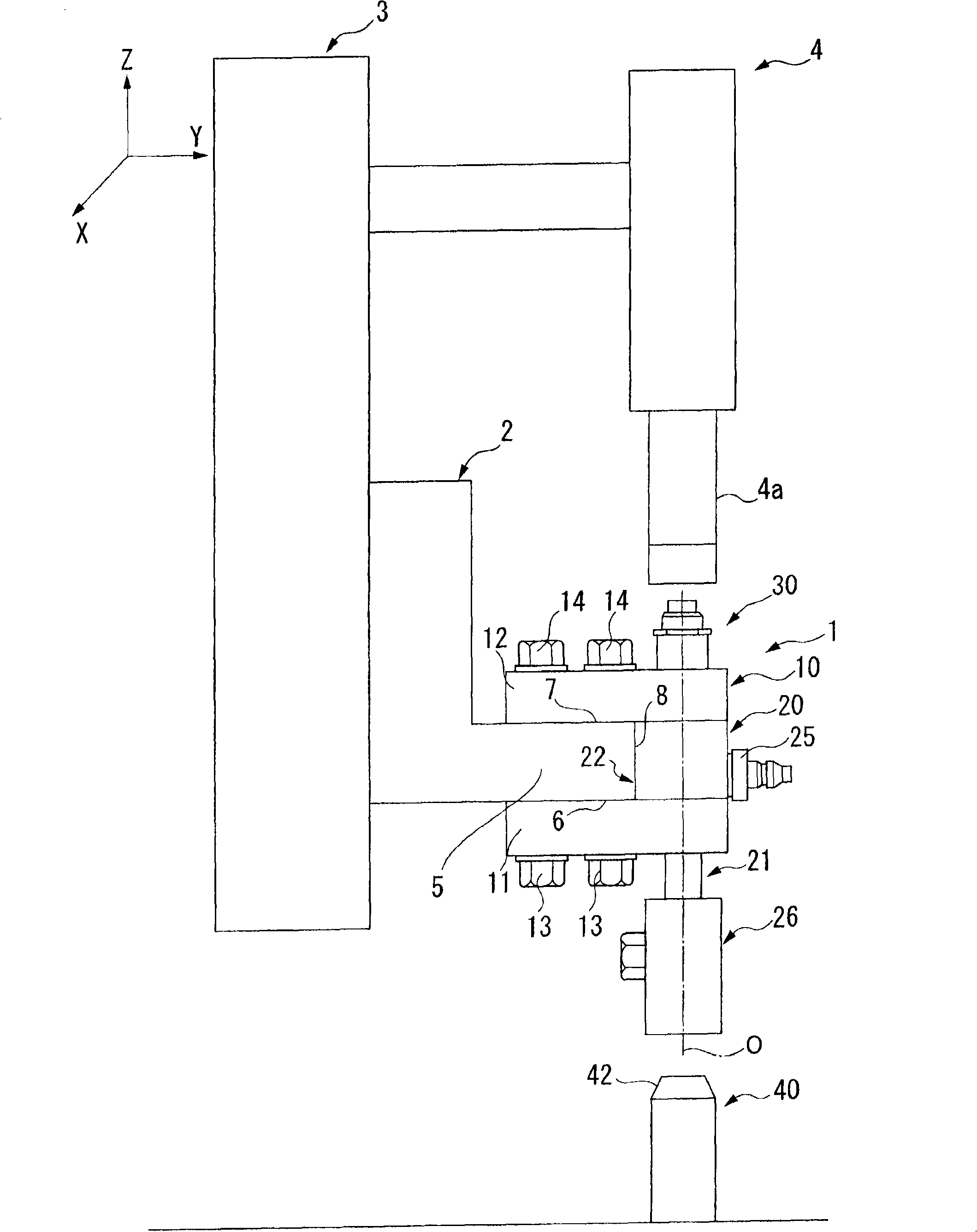

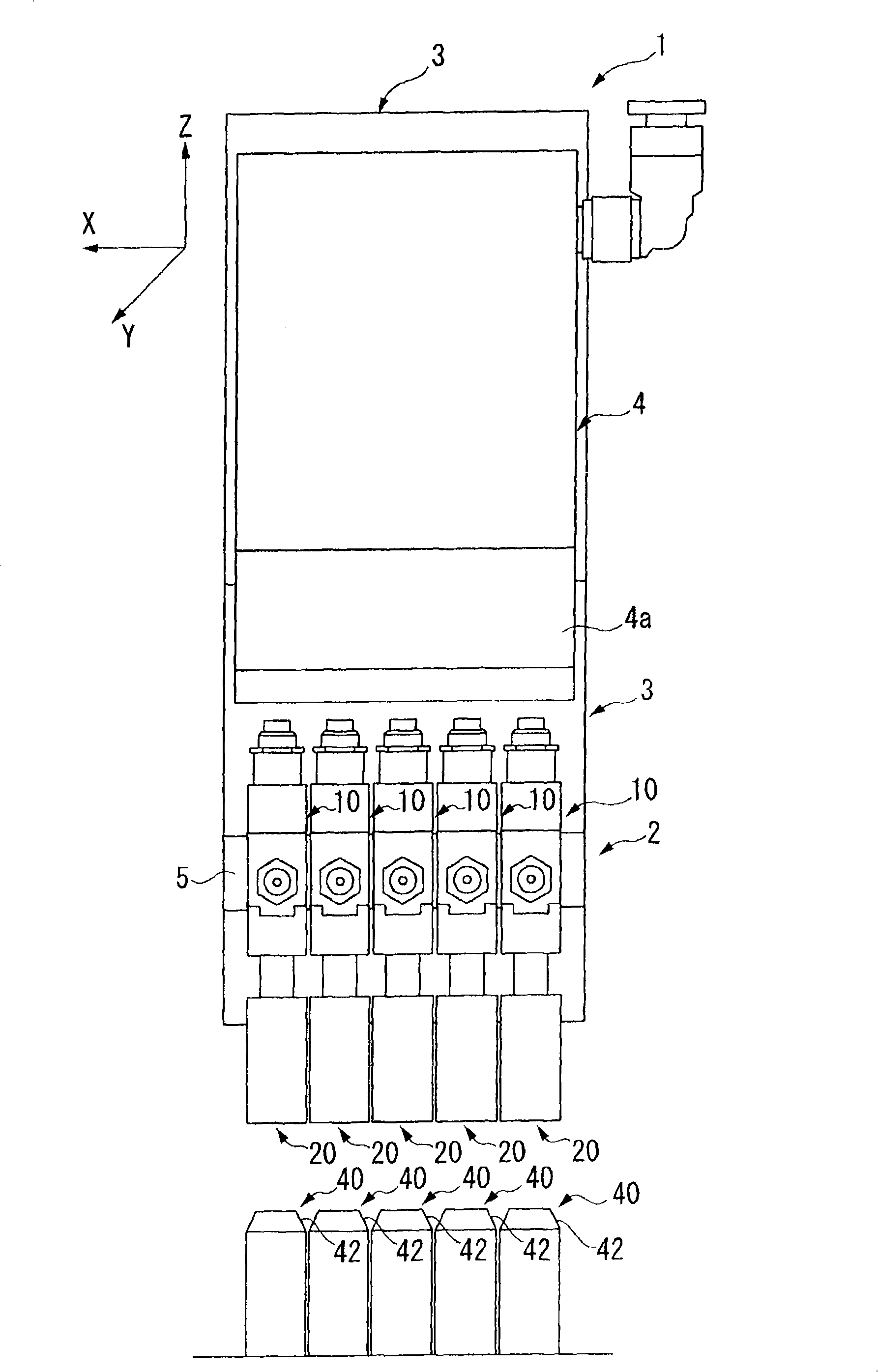

[0052] figure 1 It is a side view showing the floating chuck unit of this embodiment, figure 2 It is a side sectional view showing the floating chuck unit of this embodiment, and FIG. 3 is a side sectional view of a floating chuck device constituting the floating chuck unit, Figure 4 It is a partially enlarged view of Fig. 3 .

[0053] Such as figure 1 and figure 2 As shown, the floating chuck unit 1 of this embodiment is constituted by arranging a plurality of (five in this embodiment) floating chuck devices 10 in parallel, and each of the floating chuck devices 10 is installed by means of an angle iron (angle) 2 on the mobile substrate 3 . Furthermore, directly above t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com