Floating spindle

A main shaft and moving ring technology, applied in the field of floating main shaft, can solve the problems of low processing efficiency, broken tool castings, rising product defect rate, etc., and achieve the effect of prolonging the service life and avoiding rigid collision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

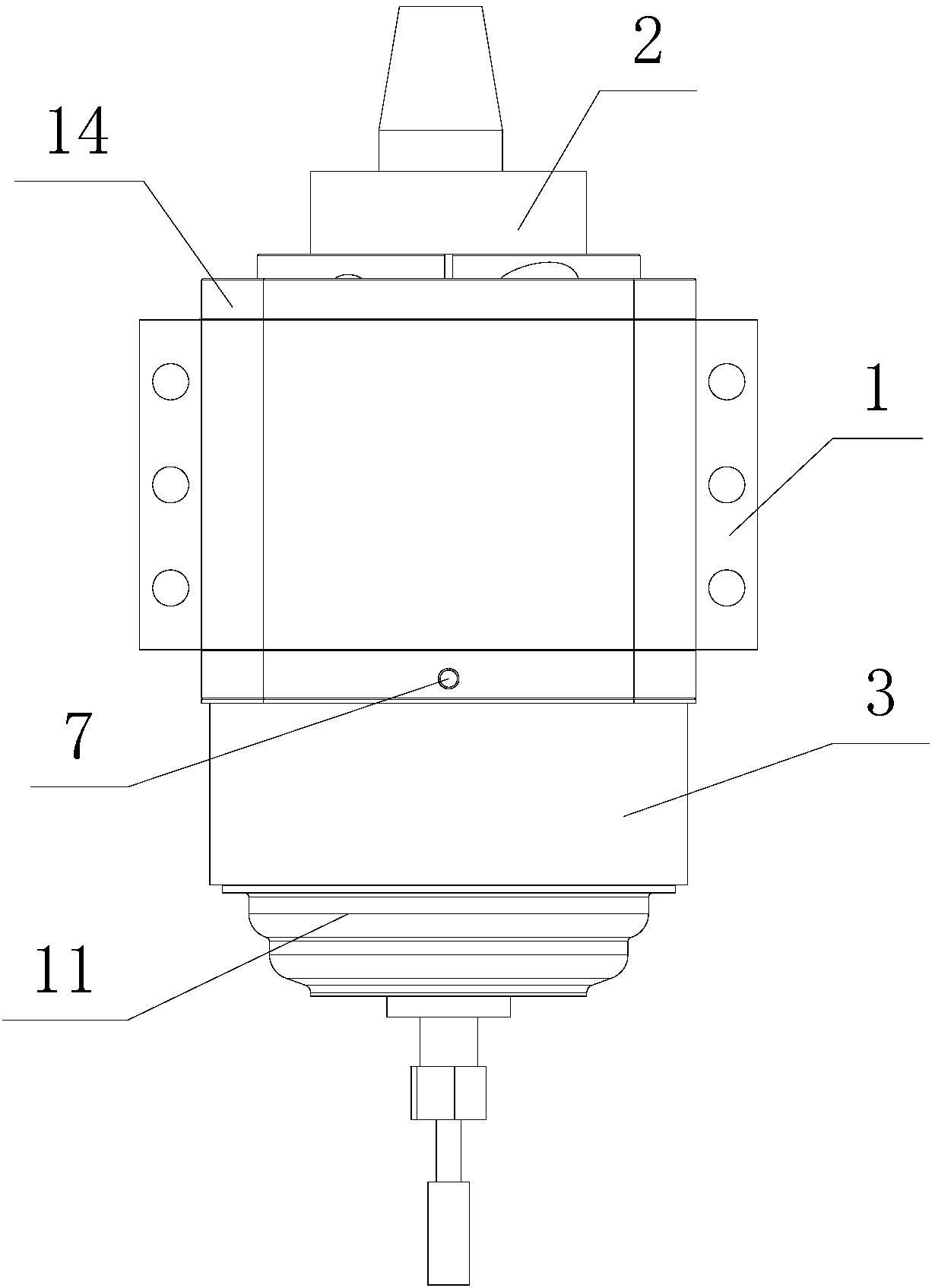

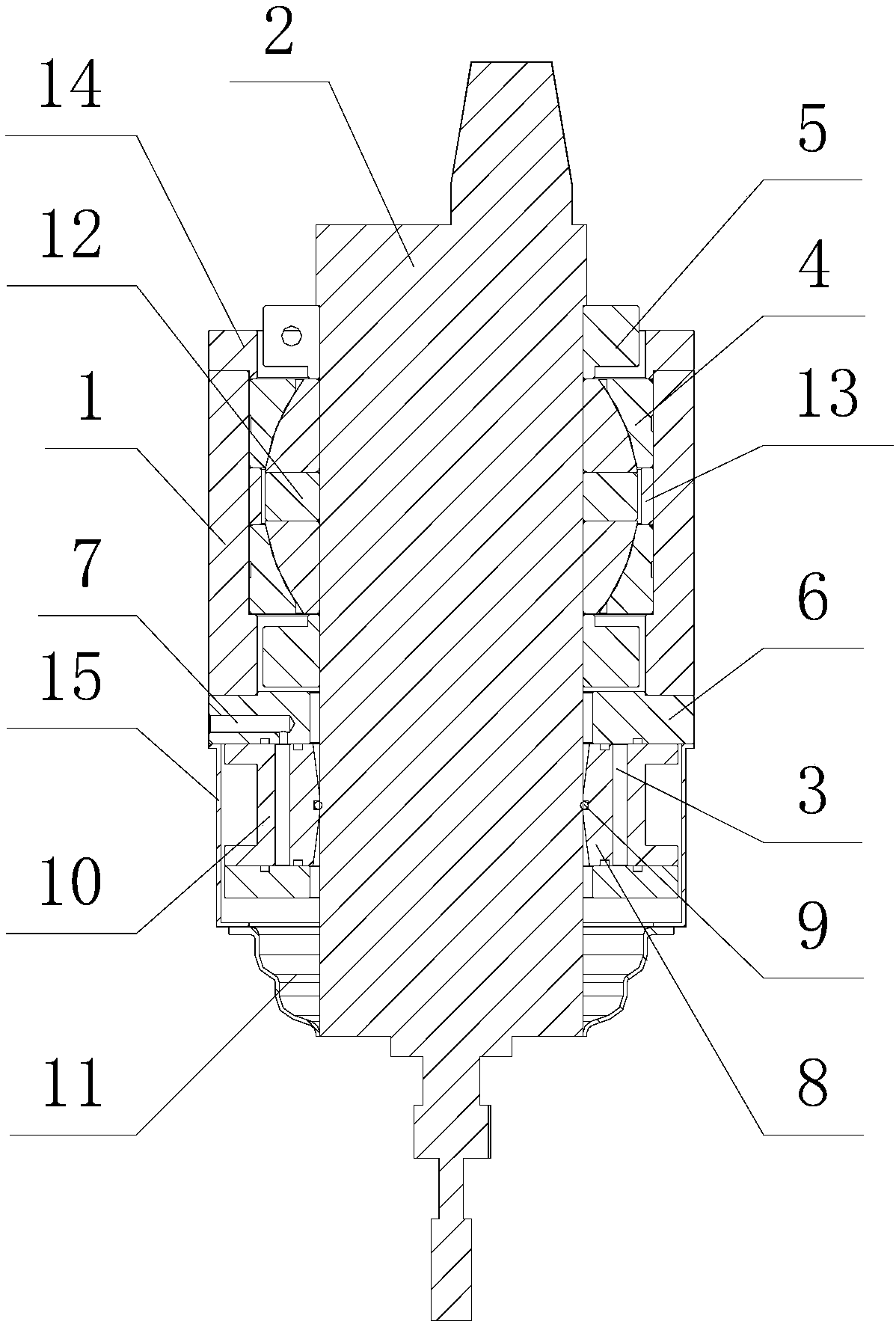

[0020] Such as figure 1 and figure 2 As shown, the floating spindle provided by this embodiment includes a coaxial installation housing 1, a spindle body 2 and an air pressure chamber 3. Inside the housing 1, the lower part is located in the air pressure chamber 3, the top of the installation housing 1 is provided with an end cover 14, and the installation housing 1 is provided with an angular contact joint bearing 4, and the angular contact joint bearing 4 is sleeved on the upper part of the main shaft body 2. An inner lining ring 12 is provided between the inner wall of the angular contact spherical plain bearing 4 and the outer wall of the main shaft body 2, and an outer lining ring 13 is provided between the outer wall of the angular contact spherical plain bearing 4 and the inner wall of the installation shell 1. The top of the angular contact spherical plain bearing 4 and the The bottom is respectively provided with a spindle limit lock ring 5, and the two spindle limi...

Embodiment 2

[0023] This embodiment is basically the same as Embodiment 1, except that the air inlet 7 is changed, and an air pressure regulating device is connected to the outside of the air inlet 7 through an air pipe, and the air pressure regulating device includes an air storage tank and an air pressure regulating valve. , the air inlet 7 is connected to the air storage tank through an air delivery pipe, and the air delivery pipe is provided with an air pressure regulating valve.

[0024] Working principle of the present invention: add compressed air into the air pressure chamber 3 from the air inlet 7 (the air pressure in the air pressure chamber 3 can be adjusted between 0.1-0.8Mpa), when the air pressure chamber 3 is filled with pressure gas, according to the principle of gas pressure, the air pressure The floating moving ring 8 in the chamber 3 will automatically move to the center of the air pressure chamber 3, the main shaft body 2 is set on the floating moving ring 8, the main sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com