Two-degree-of-freedom floating device for robot gripper

A floating device and robot technology, applied in the field of robots, can solve problems such as difficulty in meeting assembly requirements, and achieve the effects of energy-saving operation, compact overall structure, and reliable locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

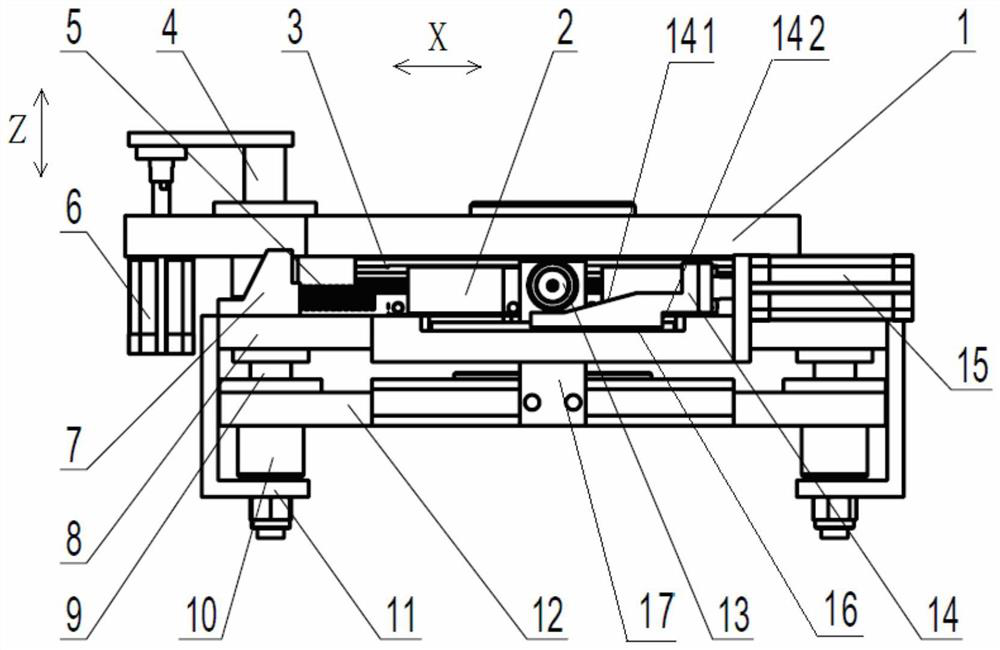

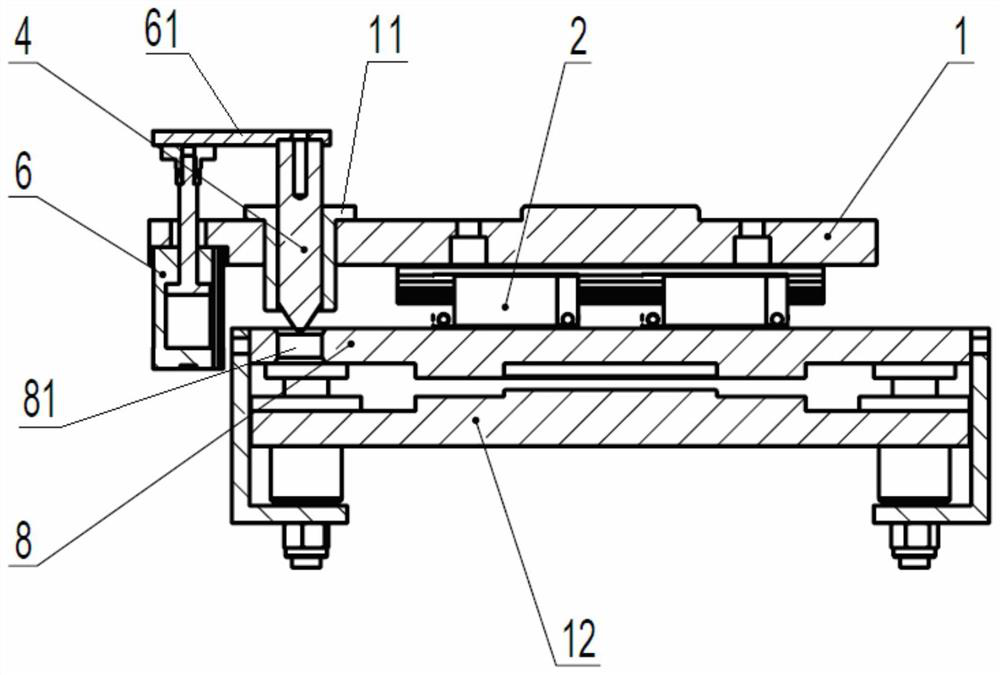

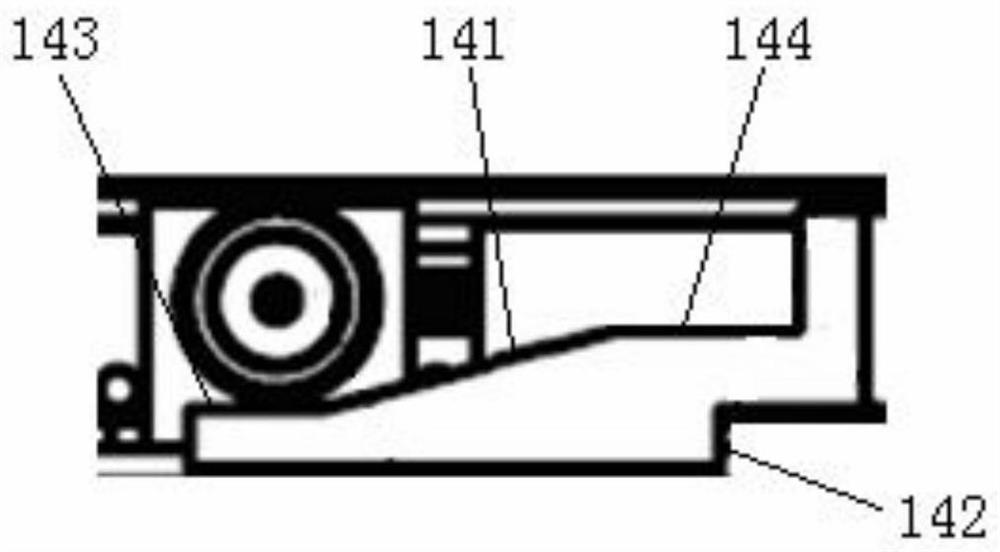

[0024] Such as Figure 1~2 As shown, the present invention includes a robot mounting plate 1, a mounting base plate 8, a jaw mounting plate 12, an X-axis locking mechanism and a Z-axis locking mechanism, wherein the mounting base plate 8 is mounted on the robot mounting plate 1 movably along the X direction, and clamping The claw mounting plate 12 is mounted on the mounting base 8 movably along the Z axis, the X-axis locking mechanism is arranged on the robot mounting plate 1, and the mounting base 8 is locked by the X-axis locking mechanism, and the Z-axis locking mechanism is located on the The mounting base plate 8 and the jaw mounting plate 12 are locked by the Z-axis locking mechanism. When the present invention works, the robot mounting plate 1 is connected to the end of the robot, and the jaw mounting plate 12 is connected to the jaws.

[0025] Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com