Molding process and mould for reducing internal stress in PC lens production

A technology of internal stress and process, applied in applications, home appliances, and other home appliances, can solve the problems of mold cavity volume non-adjustability, flash internal stress, filling dissatisfaction, etc., to reduce the lens joint line, product The effect of improving the qualified rate and reducing the generation of cold material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

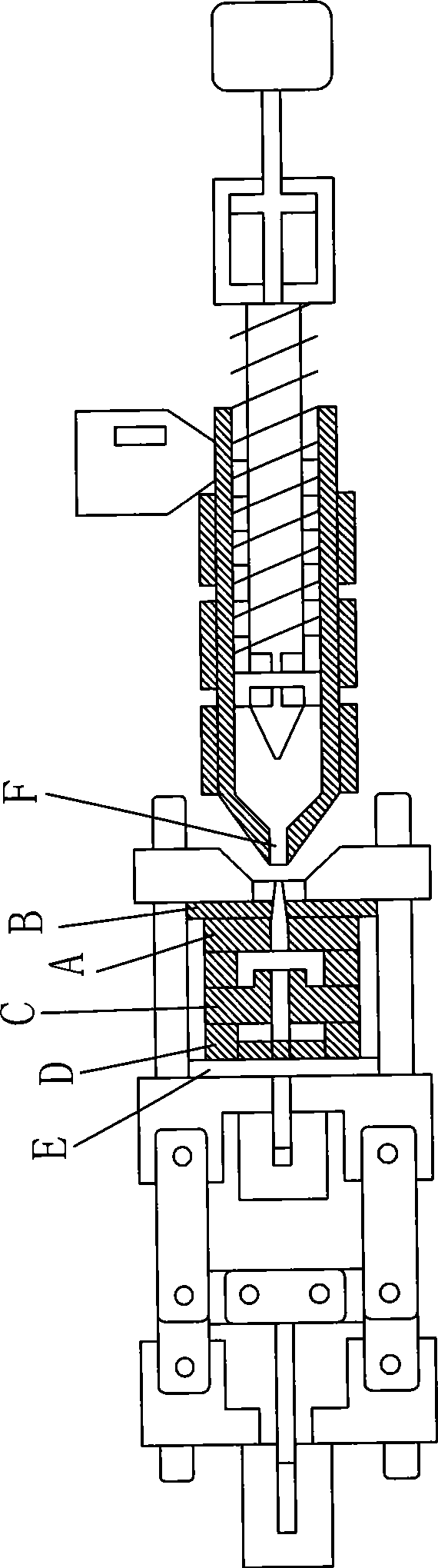

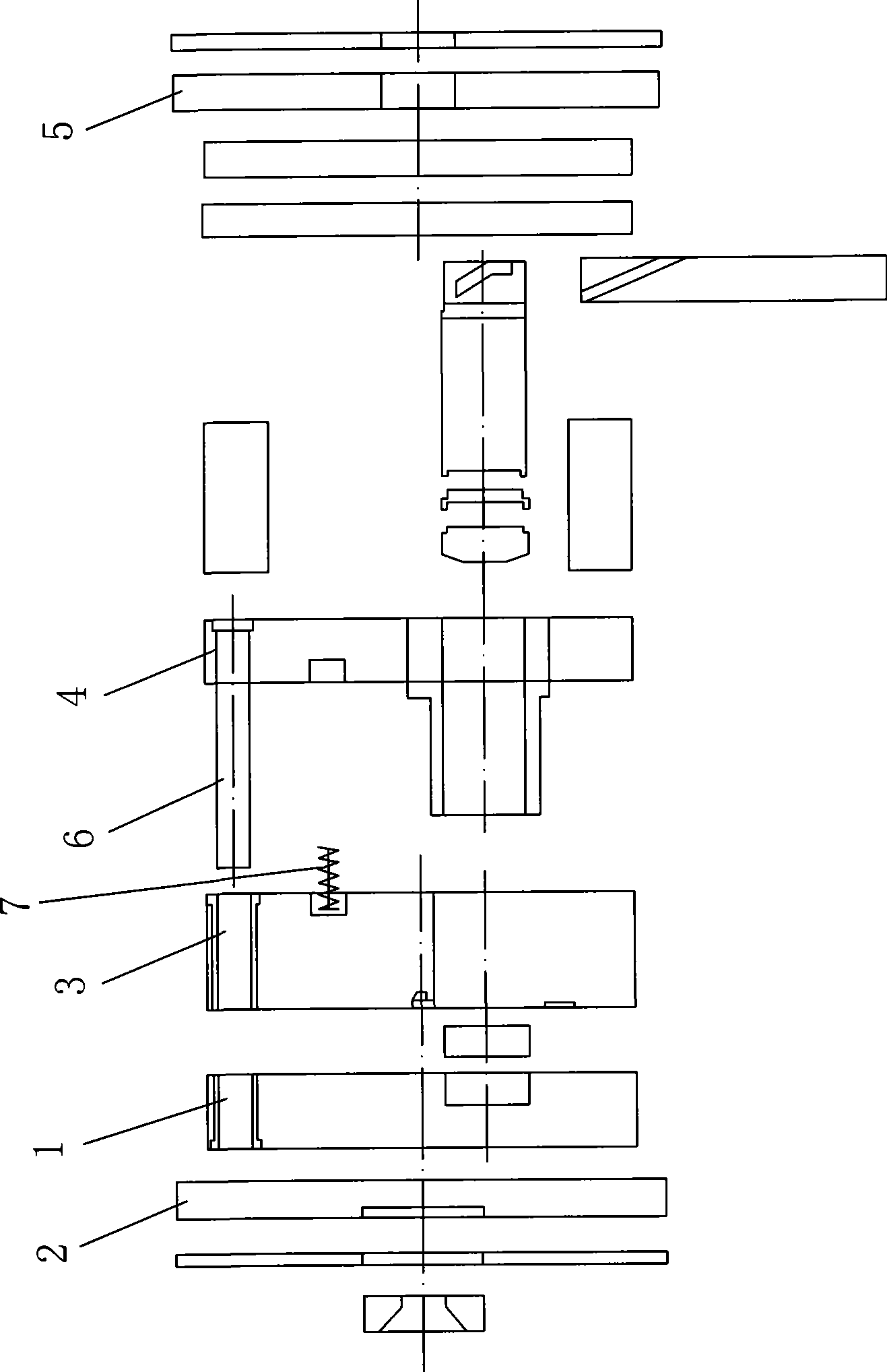

[0030] A process and mold for reducing internal stress in the production of PC lenses, the process of which is: slow mold clamping - low pressure - fixed position (adjusted according to the specification of the lens) - seating - injection (the amount of injection is adjusted according to the specification of the lens) )—compression mold clamping and simultaneous injection—high pressure mold clamping (mold fully closed)—holding pressure—feeding—cooling—mold opening (after mold opening)—ejection—top retreat—slow mold clamping; The addition of seat-in and injection processes between the high-pressure mold clamping processes can reduce the generation of internal stress. This process is injection while clamping the mold.

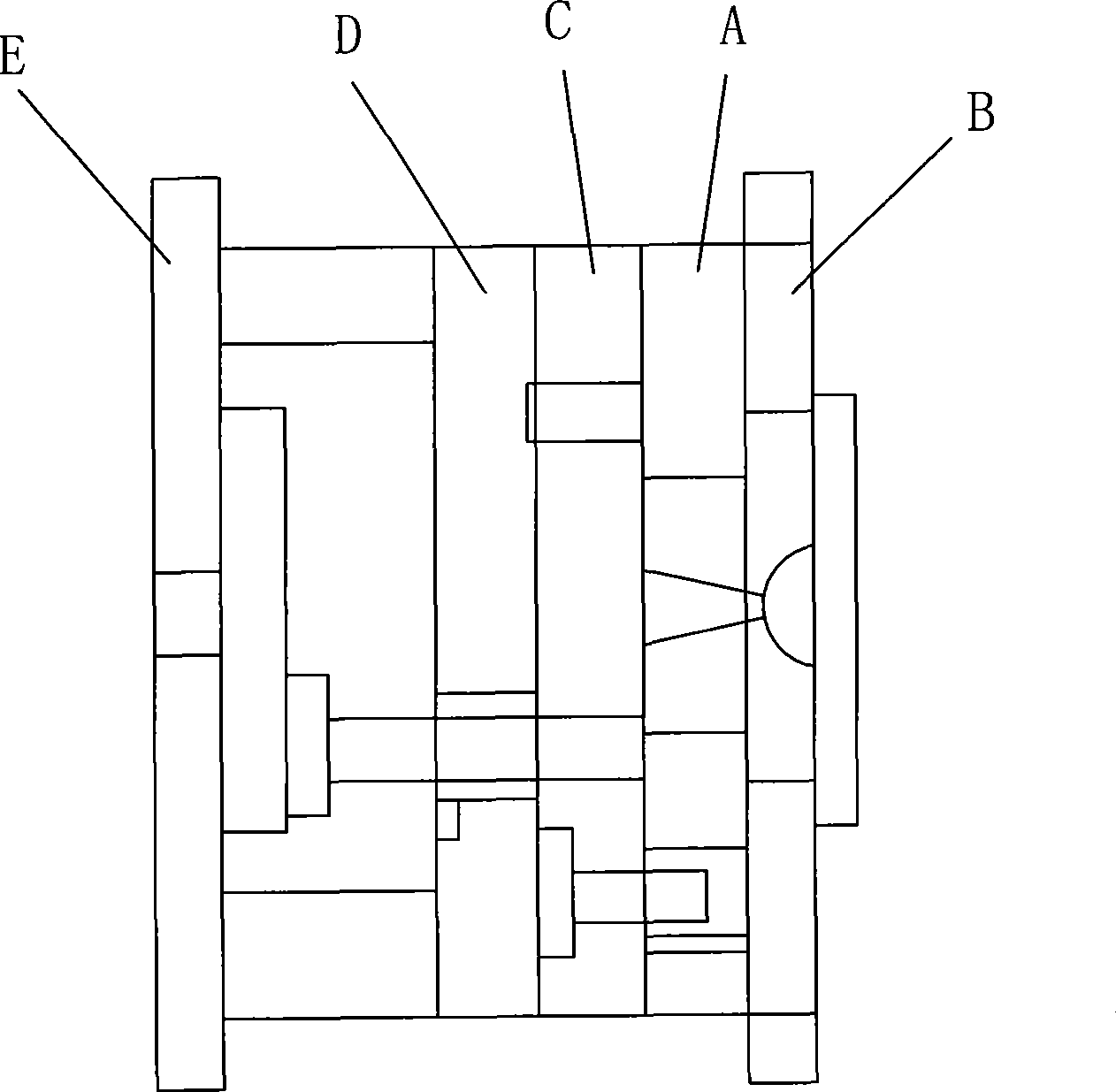

[0031] The mold includes a fixed side template 1, which is installed on the fixed side template mounting plate 2, and a movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com