Reinforced glass substrate

A tempered glass and substrate technology, applied in glass molding, glass molding, glass manufacturing equipment, etc., can solve the problem of significantly improving the mechanical strength of glass substrates, achieving glass ion exchange performance and devitrification resistance at the same time, and difficult Maintaining the mechanical strength of the glass substrate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Hereinafter, the present invention will be described based on examples.

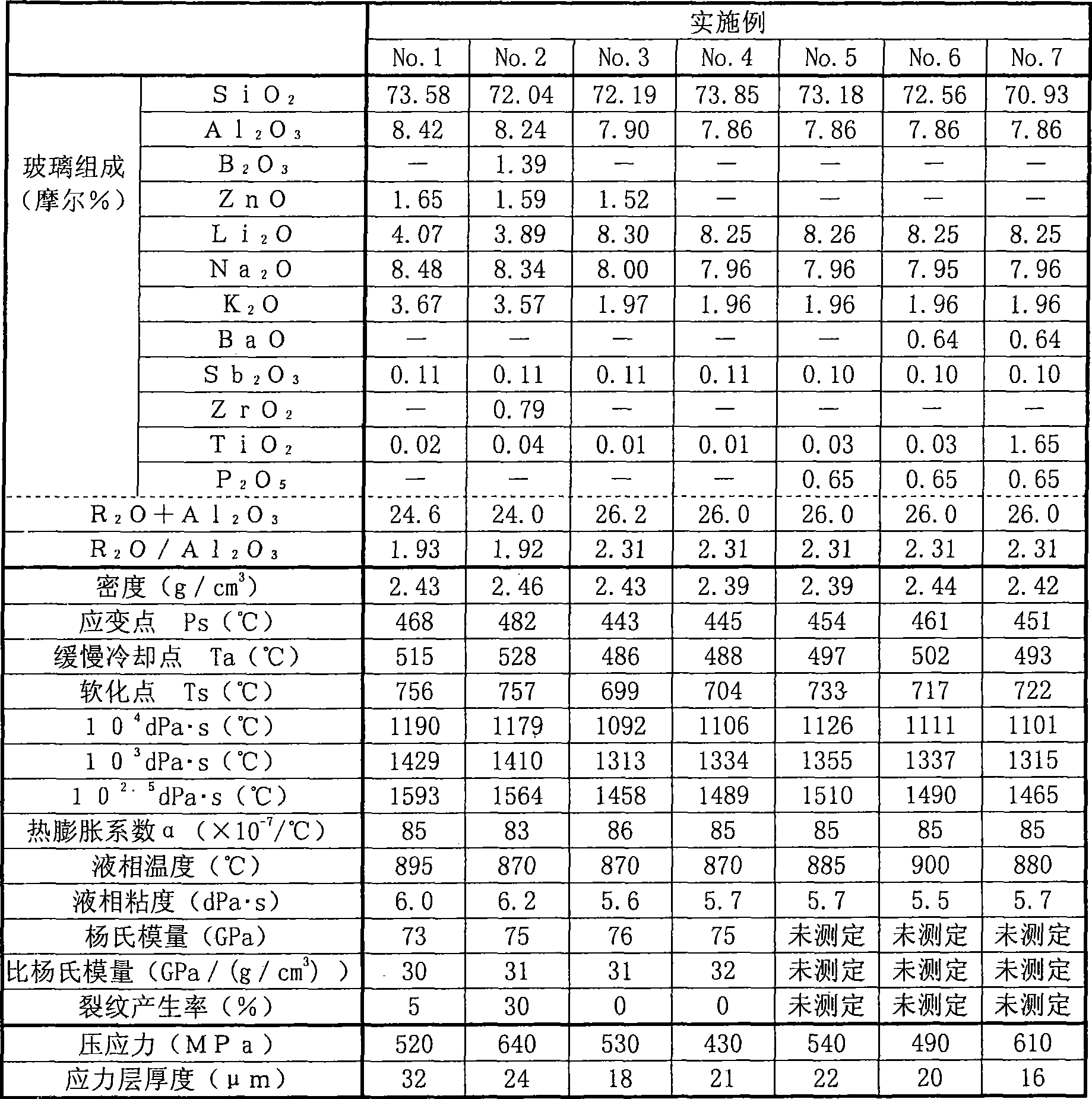

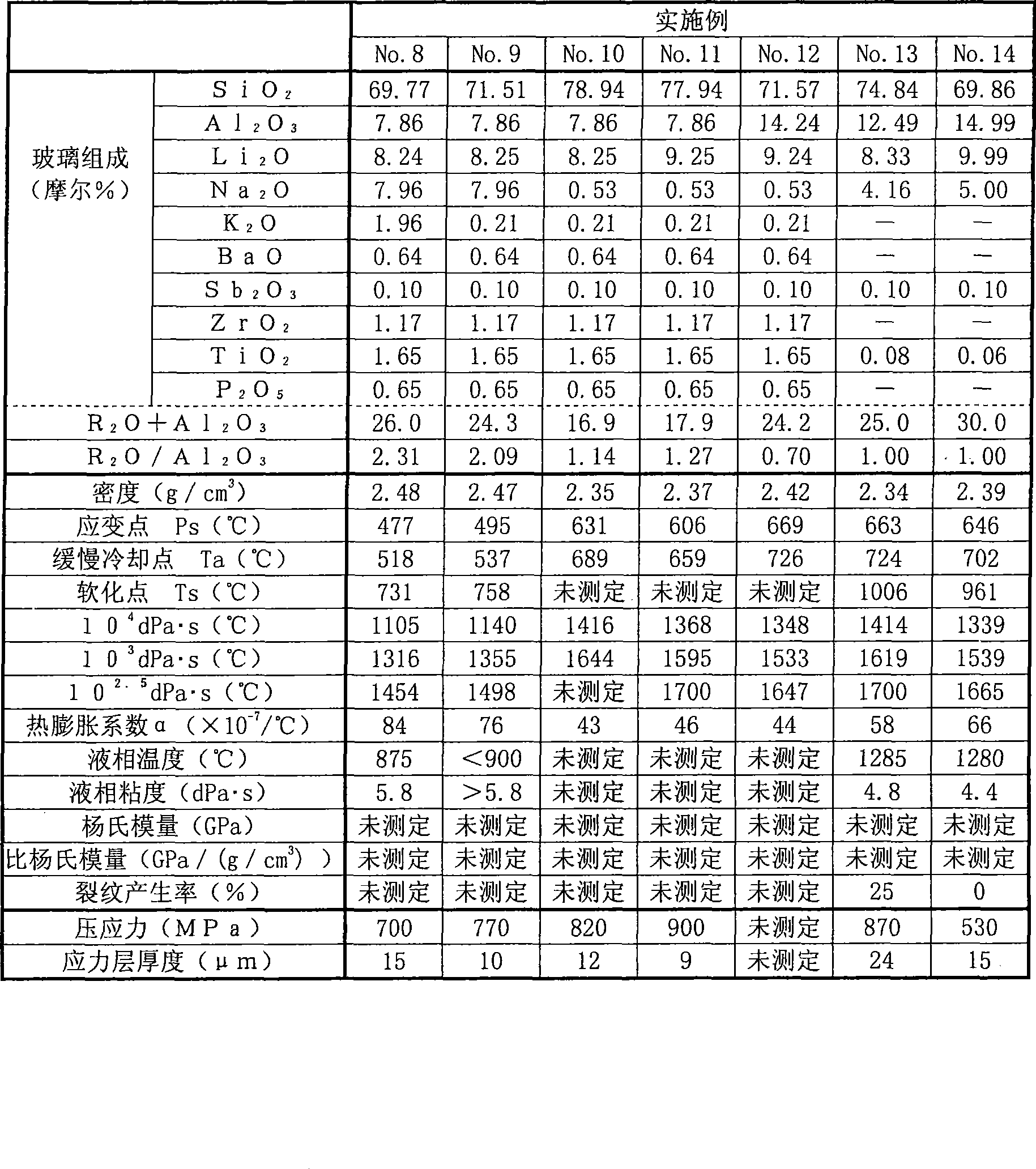

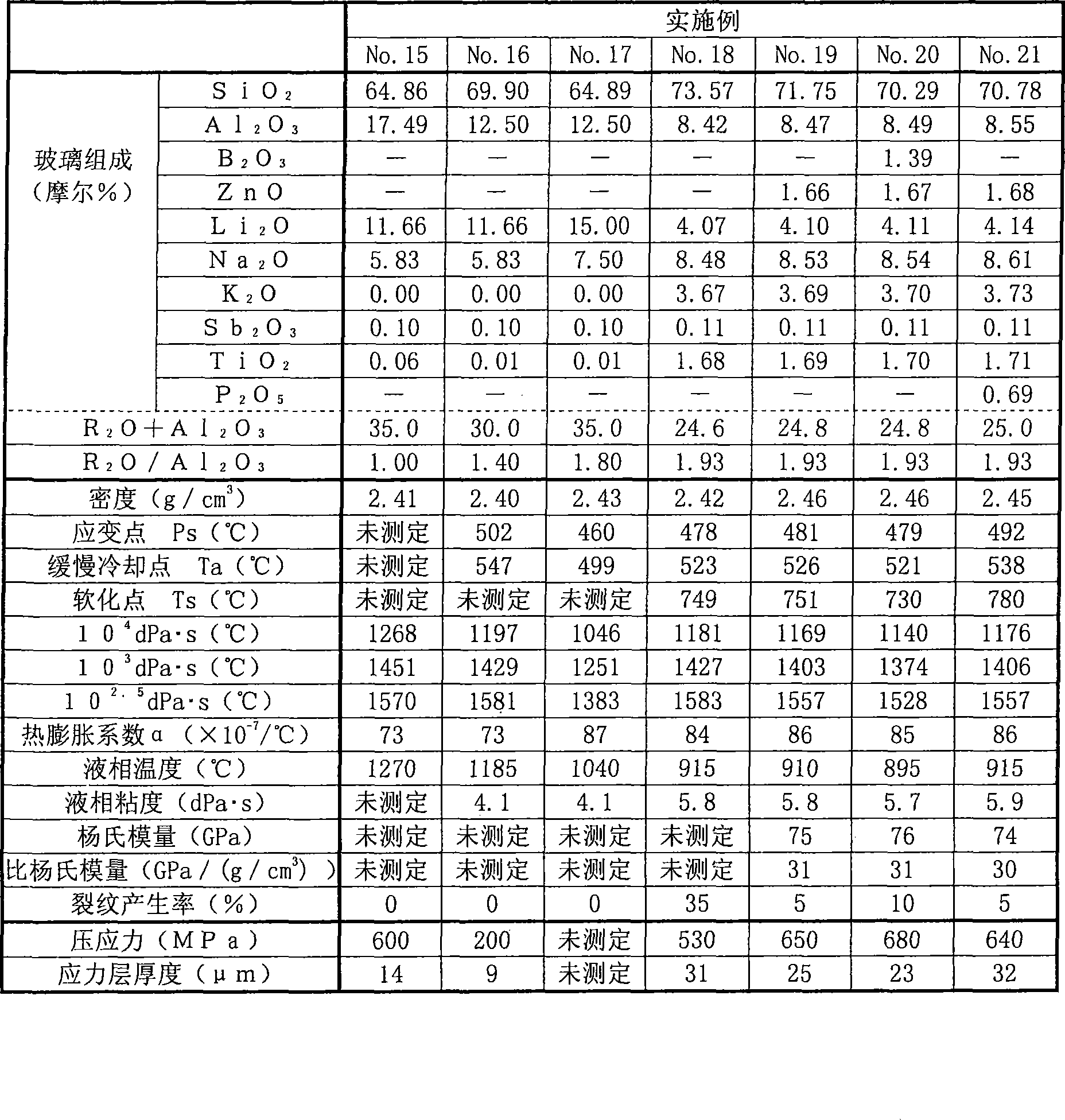

[0088] Tables 1 to 7 show examples (sample Nos. 1 to 46) of the present invention and comparative examples (sample Nos. 47 and 48) of the present invention.

[0089] 【Table 1】

[0090]

[0091] 【Table 2】

[0092]

[0093] 【table 3】

[0094]

[0095] 【Table 4】

[0096]

[0097] 【table 5】

[0098]

[0099] 【Table 6】

[0100]

[0101] 【Table 7】

[0102]

[0103] Each sample was produced as follows. First, glass raw materials were blended so as to have the glass compositions shown in Tables 1 to 7, and were melted at 1600° C. for 8 hours using a platinum boat. Then, the molten glass was flowed onto a carbon plate, and formed into a plate shape. Various characteristics were evaluated about the obtained glass substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com