Method and device for reducing over-high deflection in amplitude changing process of caterpillar-band crane arm support

A technology of crawler cranes and cranes, which is applied in the direction of cranes, etc., to achieve the effect of reducing the deflection of the boom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

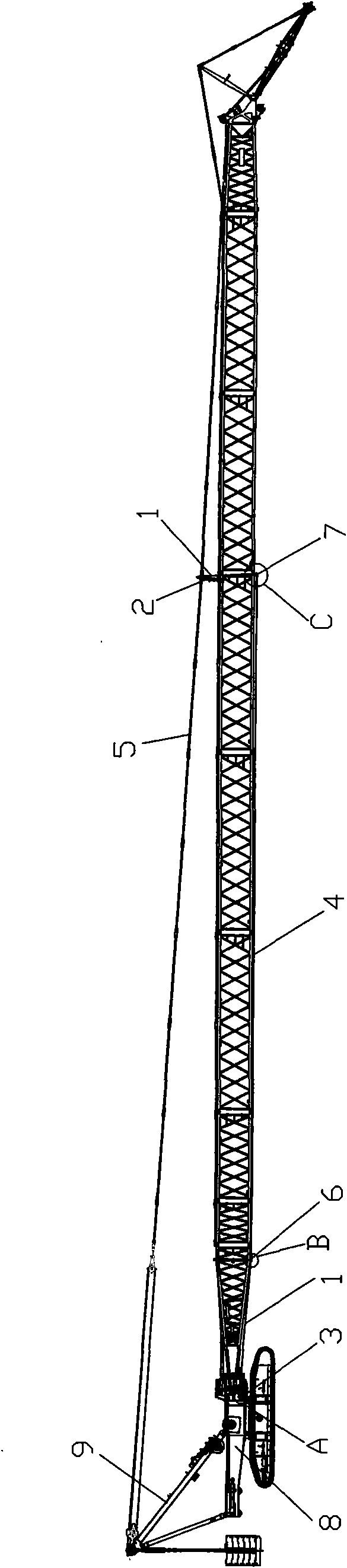

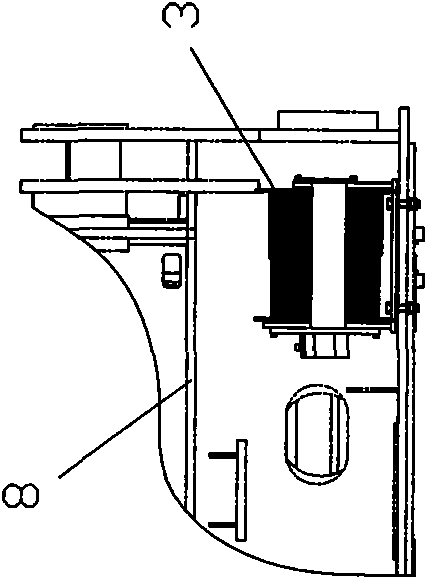

[0031] see Figure 1 to Figure 7 , the method for reducing the excessive deflection of the crawler crane jib during the luffing process of the present invention is to install a steel wire rope 1 at the position where the deflection of the jib 4 of the crane 8 is the largest, and the steel wire rope 1 is connected with a retractable waist rope device 2. A support point of the rope device 2 is located on the crane pull plate 5 (or pull rope, or pull pipe), the other end is connected to the jib frame 4, and the other end of the wire rope 1 is connected to a hoist 3, and the hoist 3 is arranged on a crawler crane 8 host.

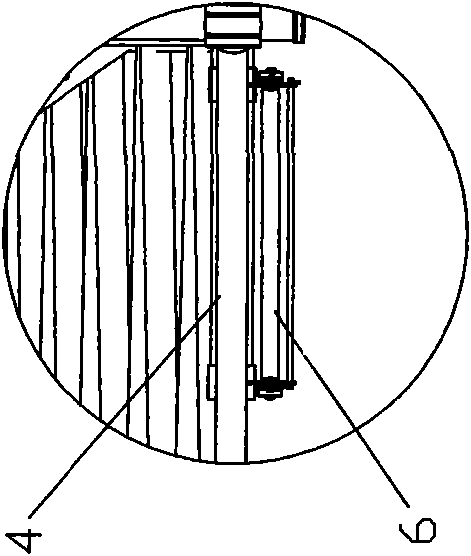

[0032] Described waist rope device 2, it is suspension type, comprises, upper pulley group 21, and this upper pulley group comprises upper fixed support 211, is arranged on the upper pulley 212 of upper fixed support 211 by s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com