Shutter type hydraulic self-control gate

A hydraulic automatic control, shutter-type technology, applied in water conservancy projects, marine engineering, coastline protection and other directions, can solve the problems of slow opening and closing speed, high technical level requirements, large opening and closing resistance of lying down doors, etc., to reduce navigation. The effect of water level error, shortening navigation time and improving navigation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

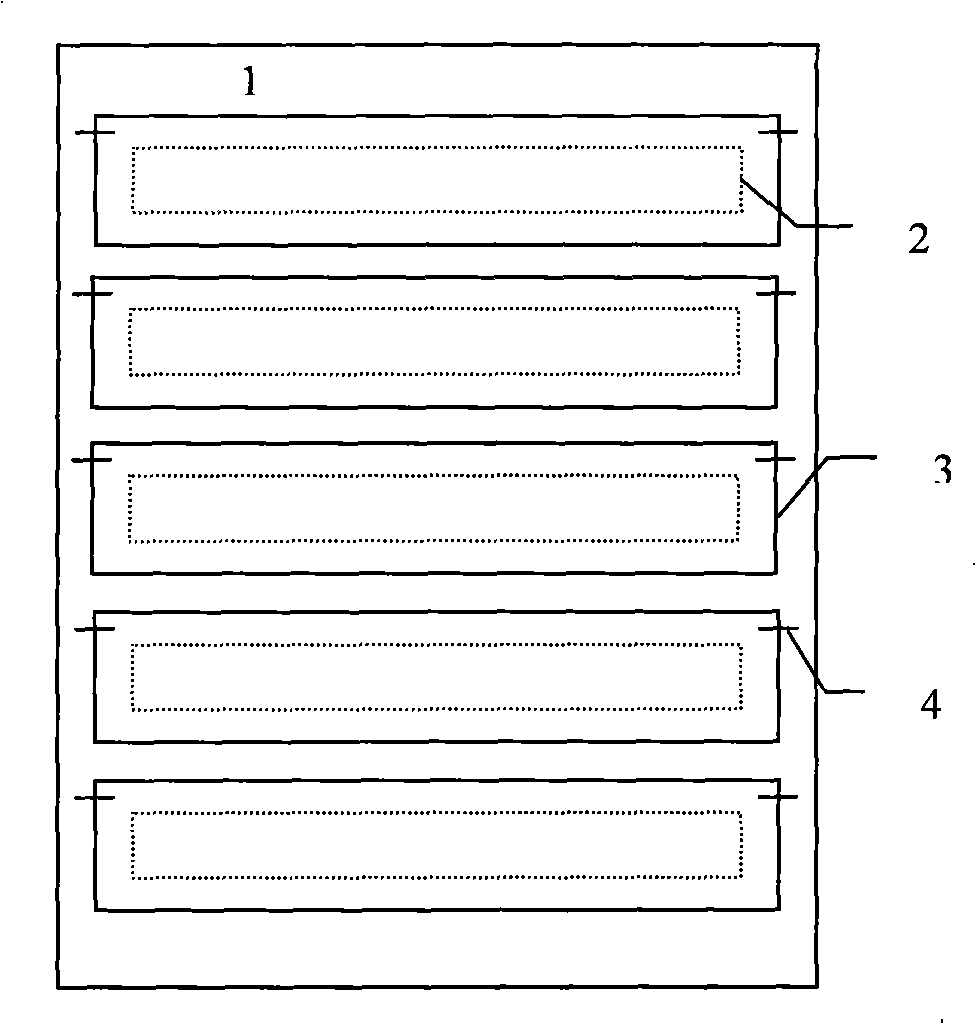

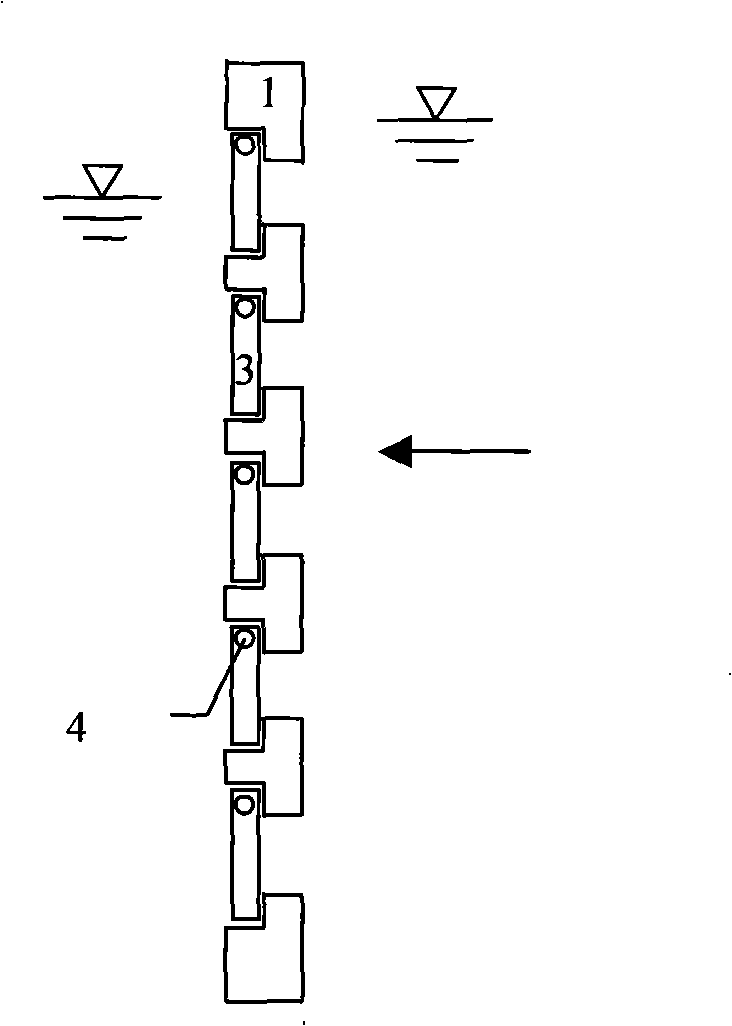

[0015] like figure 1 , 2 As shown, the louver type hydraulic automatic control gate includes a gate frame 1, a window mullion 2, a small door leaf 3 and a small door shaft 4; a plurality of window mullions 2 are arranged in the gate frame 1, and a small door shaft 4 is arranged on the top of the window mullion 2, Hang the small door leaf 3 on the small door shaft 4.

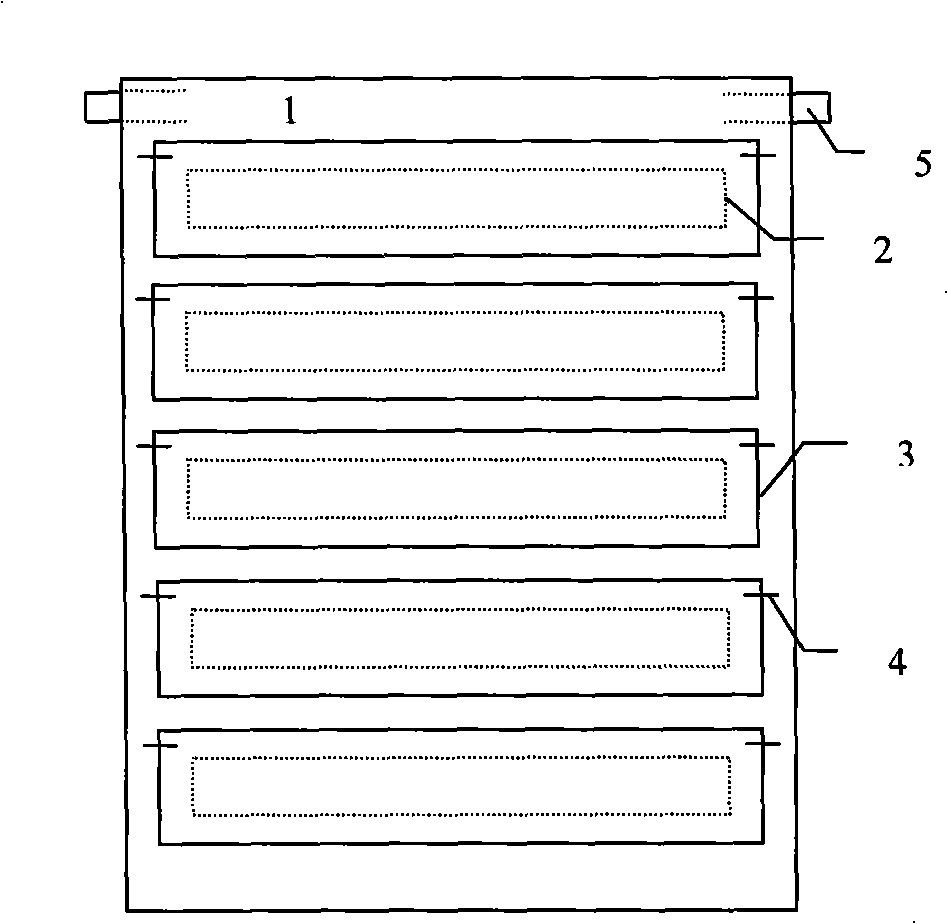

[0016] like image 3 As shown, the louver type hydraulic automatic control gate includes a gate frame 1, a window mullion 2, a small door leaf 3 and a small door shaft 4; a plurality of window mullions 2 are arranged in the gate frame 1, and a small door shaft 4 is arranged on the top of the window mullion 2, A small door leaf 3 is hung on the small door shaft 4, and a large door shaft 5 is arranged on the top of the gate frame 1 to form a jacking type louver hydraulic automatic control gate.

[0017] like Figure 4 As shown, the louver type hydraulic automatic control gate includes a gate frame 1, a window m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com