Connection structure between door body and sliding rail of car shed door

A technology of slide rail connection and door body, which is applied to the layout of wing leaves, door/window accessories, building structures, etc. Smooth sliding, saving mechanism materials and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

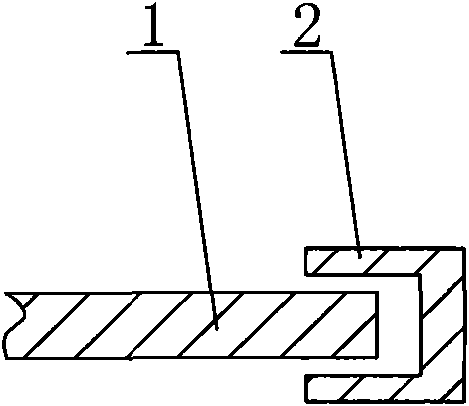

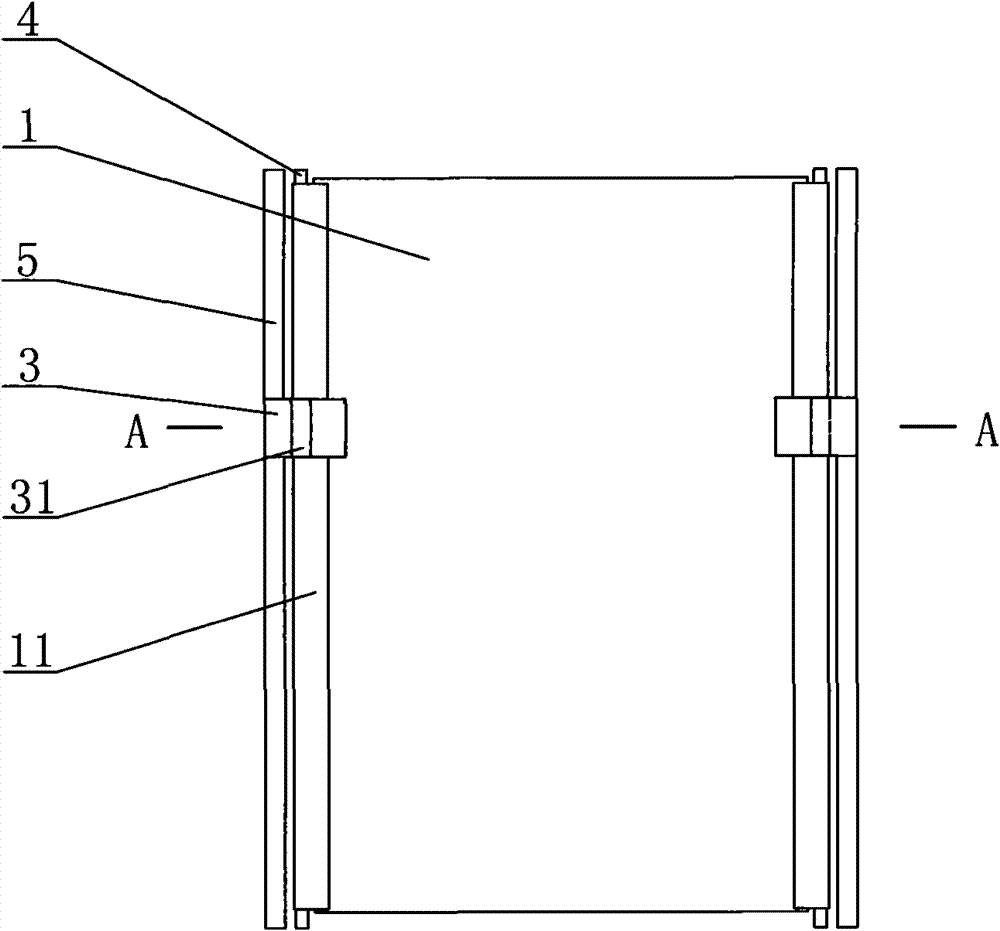

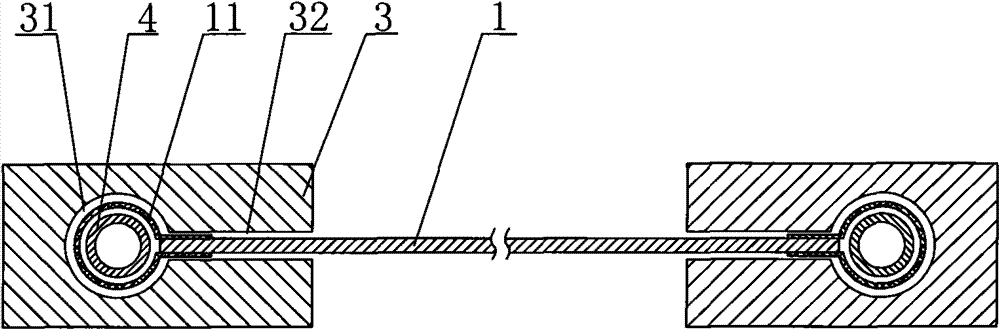

[0016] like figure 2 , image 3 The connection structure between the door body and the slide rail of the carport door of the present invention as shown includes a track 4 arranged on the side of the door body 1 and a fastener 3 arranged on the door frame 5 to fix the rail 4, and the fastener 3 is installed in the middle of the door frame The location and the number of installations can be determined according to actual needs, and the upper and lower ends of the door frame can also be installed for better stability. The track 4 is installed on the side of the door body 1 through a flexible connector 11, and the fastener 3 has a non-return groove mechanism that restricts the lateral movement of the track, and the track 4 is embedded in the groove together with the flexible connector 11 within the institution. The groove mechanism includes a slot 31 arranged inside the fastener 3, a bottle-neck opening 32 is provided on one side of the slot 31 to the edge of the fastener 3, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap