Flow characteristics test method and device of a plate-fin heat exchanger fin

A technology of plate-fin heat exchanger and flow characteristics, which is applied in the field of fluid mechanics and can solve problems such as difficult fin quality judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

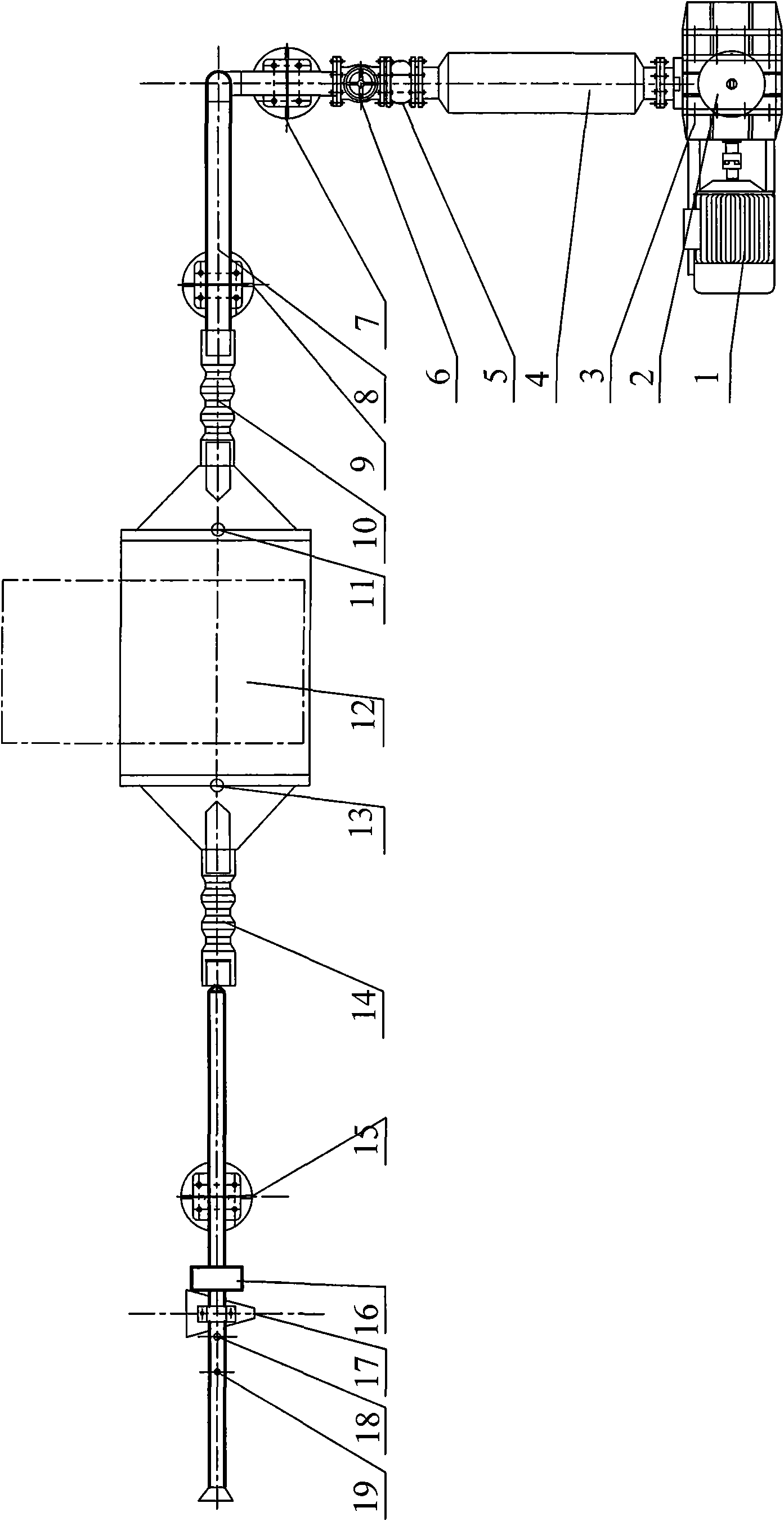

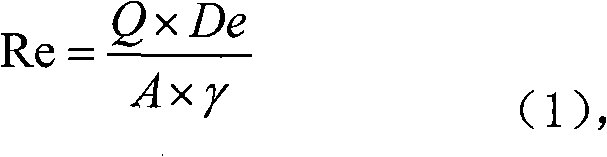

[0032] The present invention will be described in detail below with reference to the accompanying drawings: The method for testing the fin flow characteristics of the plate-fin heat exchanger of the present invention is to use a fin flow characteristics test device with computer control and calculation functions to measure air flow in real time. The pressure drop across the fins, the flow rate and the temperature before and after the fins are determined by the following technical formula (1):

[0033] Re = Q × De A × γ - - - ( 1 ) ,

[0034] Among them: Q-air flow, m 3 / s;

[0035] De——Equivalent diameter of the channel, m;

[0036] A——Circulation area, m 2 ;

[0037] γ——Kinematic viscosity, m 2 / s.

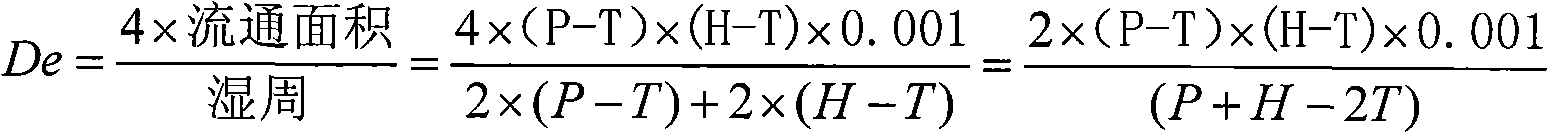

[0038] The equivalent diameter De of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap