High-voltage vacuum breaker

A vacuum circuit breaker, high-voltage technology, applied in high-voltage air circuit breakers, high-voltage/high-current switches, circuits, etc., can solve the problems of contact surface burnout, unfavorable post-open phase, unfavorable breaking inductance, etc., to achieve Reduce the opening speed, reduce shaking, and facilitate the effect of arc extinguishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

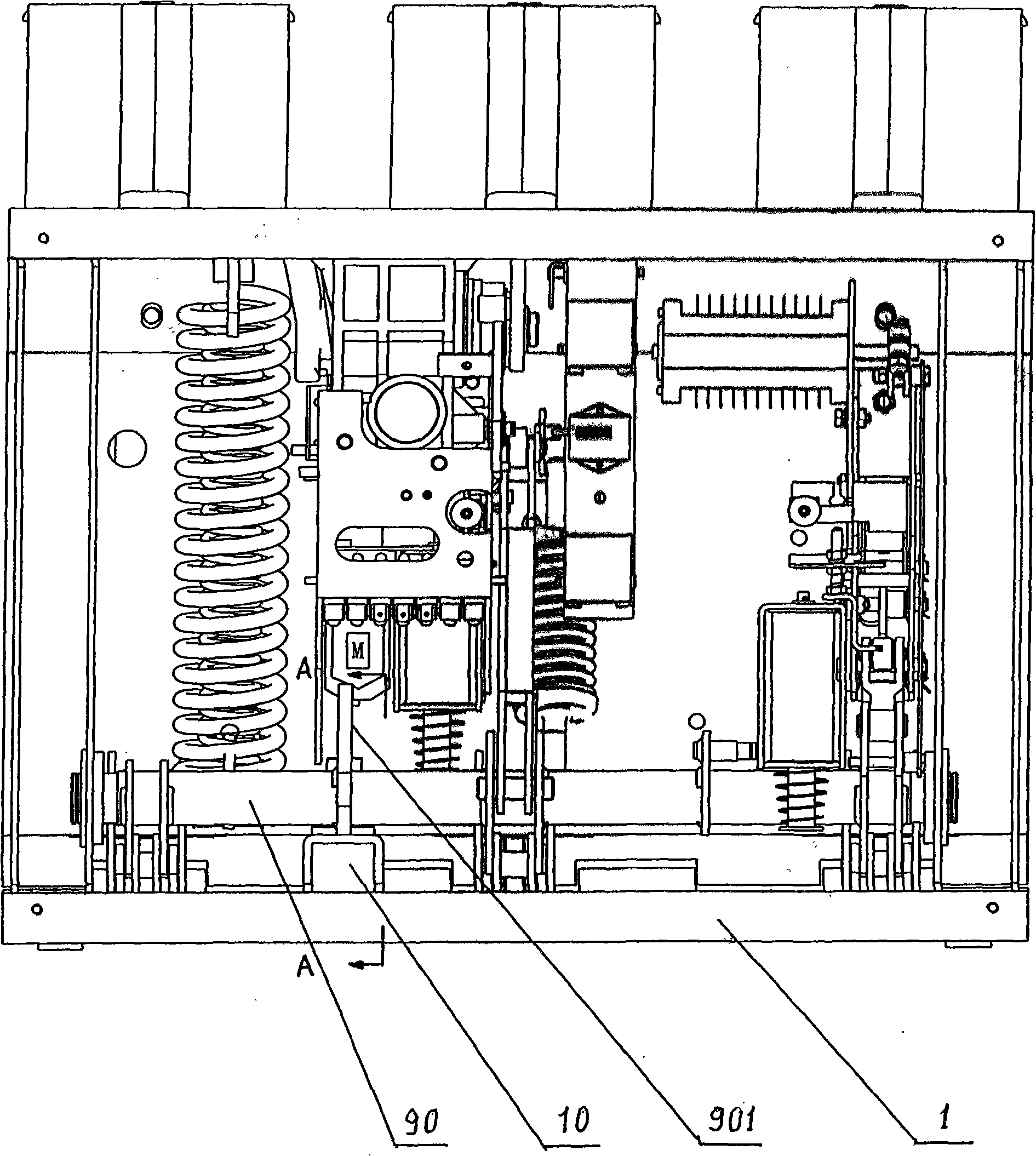

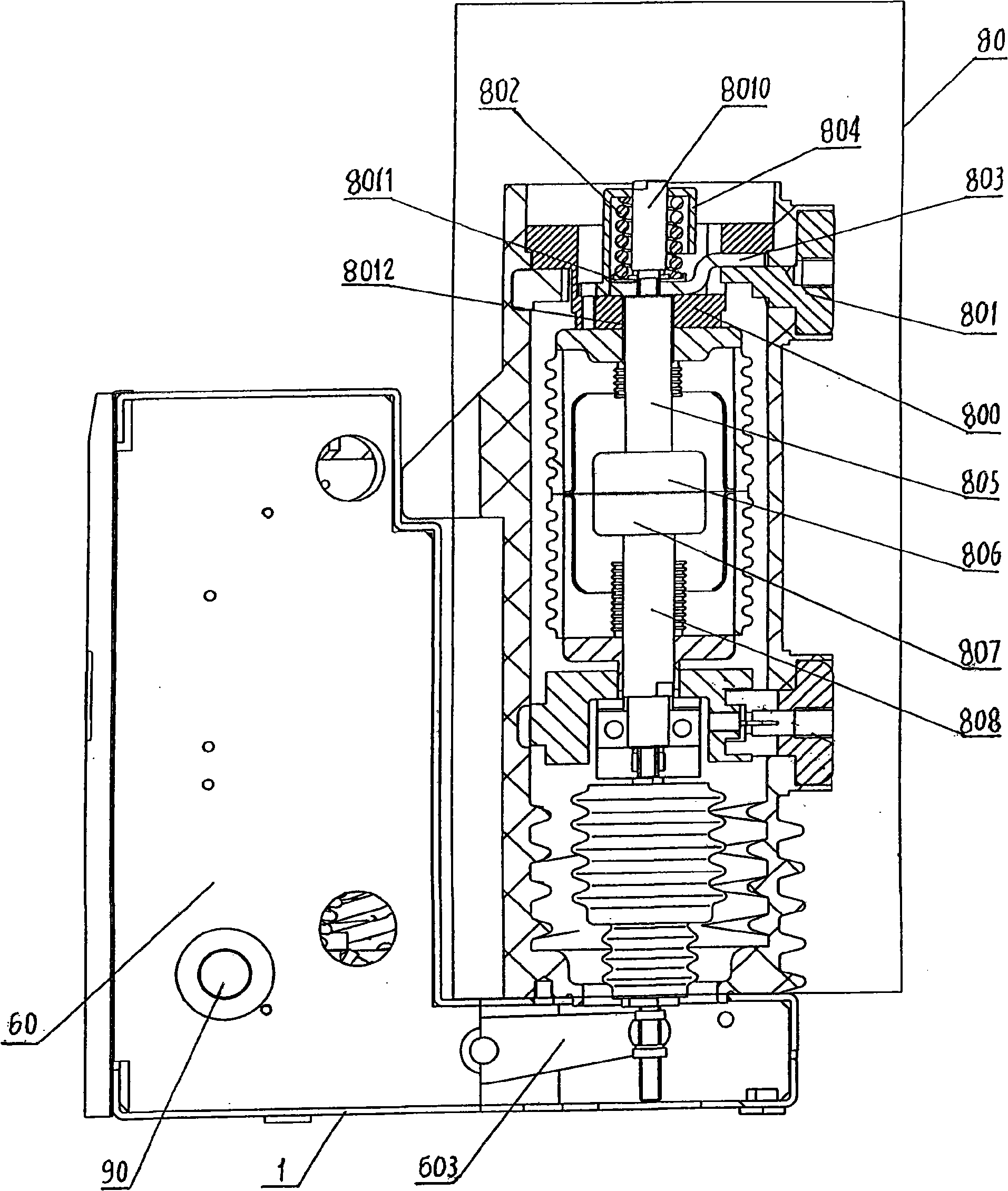

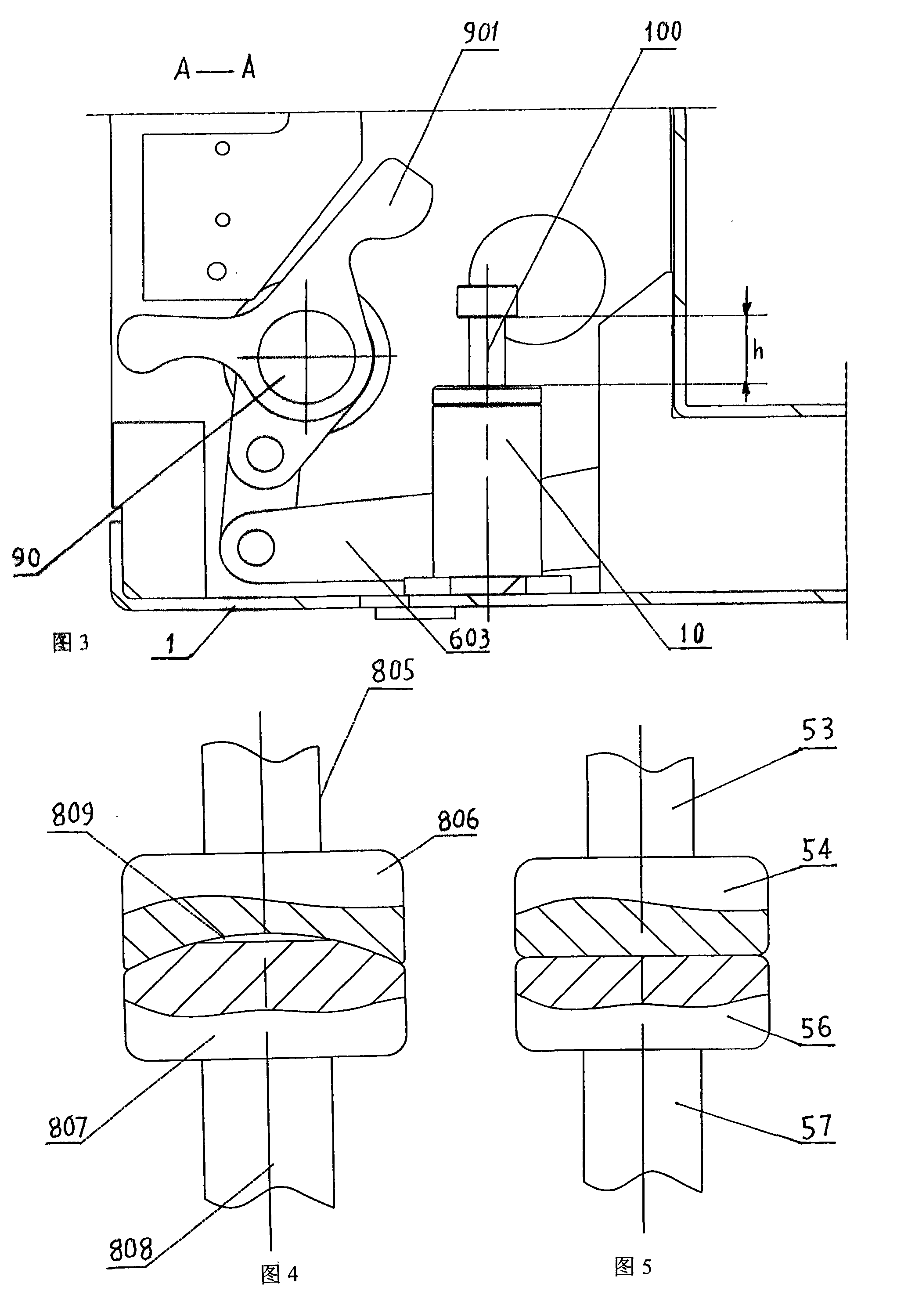

[0023] refer to figure 1 and figure 2 , The high-voltage vacuum circuit breaker of the present invention includes a frame 1 , a main shaft 90 , an operating mechanism 60 and its four-bar linkage assembly 603 , a main circuit 80 and an opening buffer 10 . The main shaft 90 is connected to one end of the four-bar linkage assembly 603 , and the other end of the four-bar linkage assembly 603 is connected to the main circuit 80 .

[0024] The main circuit 80 includes an upper bracket 800, an upper outgoing line 801, a soft connection 803, a contact spring 802, a spring cover 804 for a built-in contact spring 802, a contact spring seat 8011, an upper conductive rod 805, an upper contact 806, a lower The contact 807 , the lower conductive rod 808 and the guide rod 8010 located in the contact spring 802 . The upper conductive rod 805 passes through the through hole of the upper bracket 800 , and an insulating ring 8012 is sleeved between the upper conductive rod 805 and the throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com