Hydraulic control apparatus of an automated multi-step change-speed gearbox

一种控制装置、变速器的技术,应用在传动装置控制、带有齿的元件、皮带/链条/齿轮等方向,能够解决成本劣势结构空间、功能限制等问题,达到避免不利影响的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

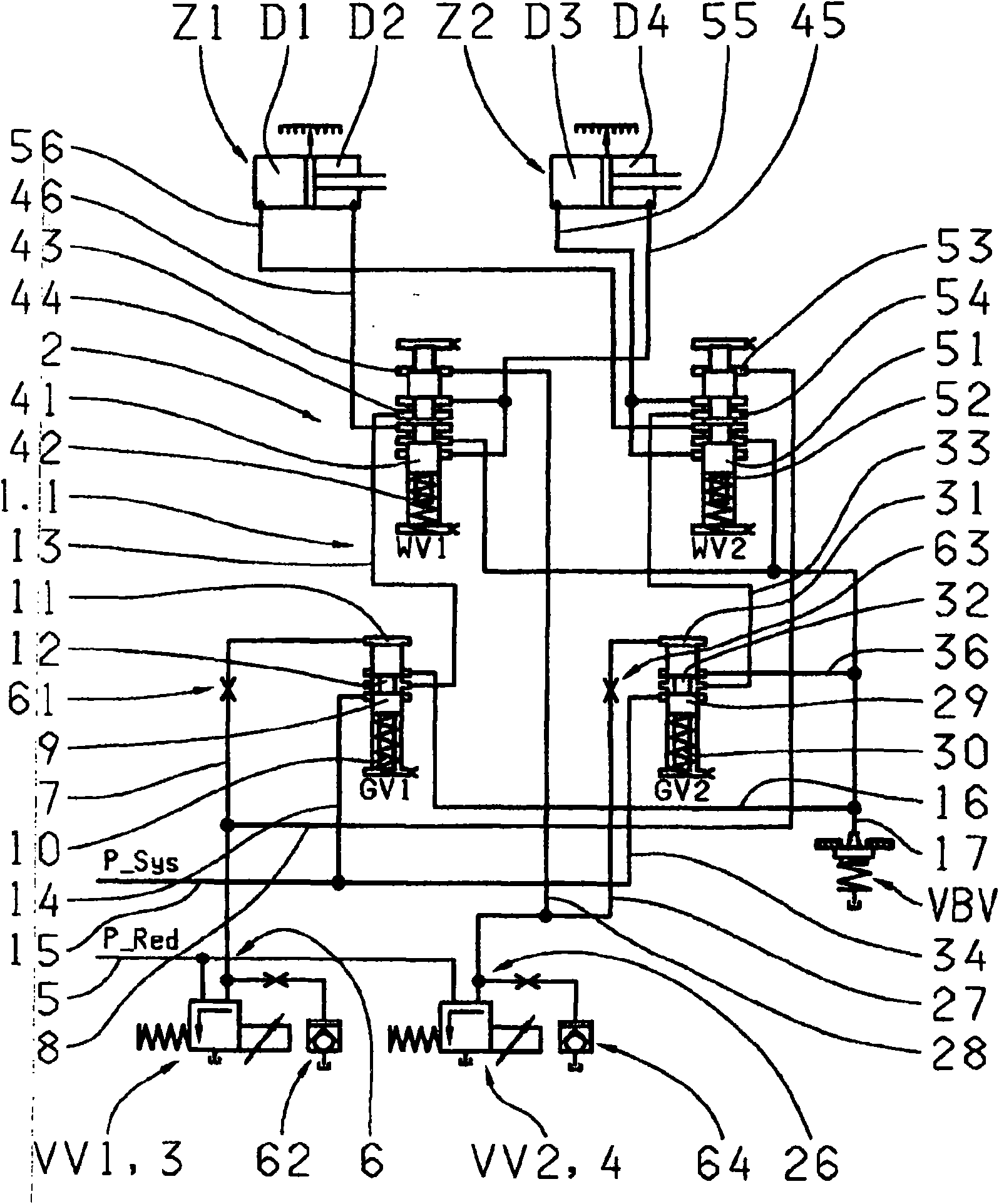

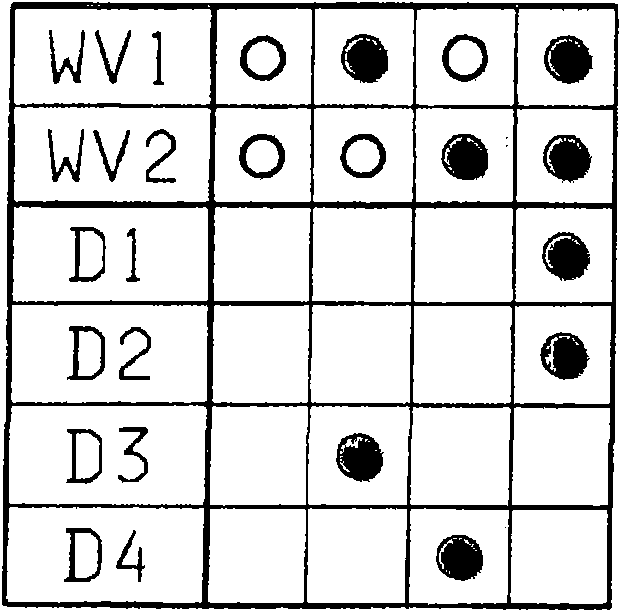

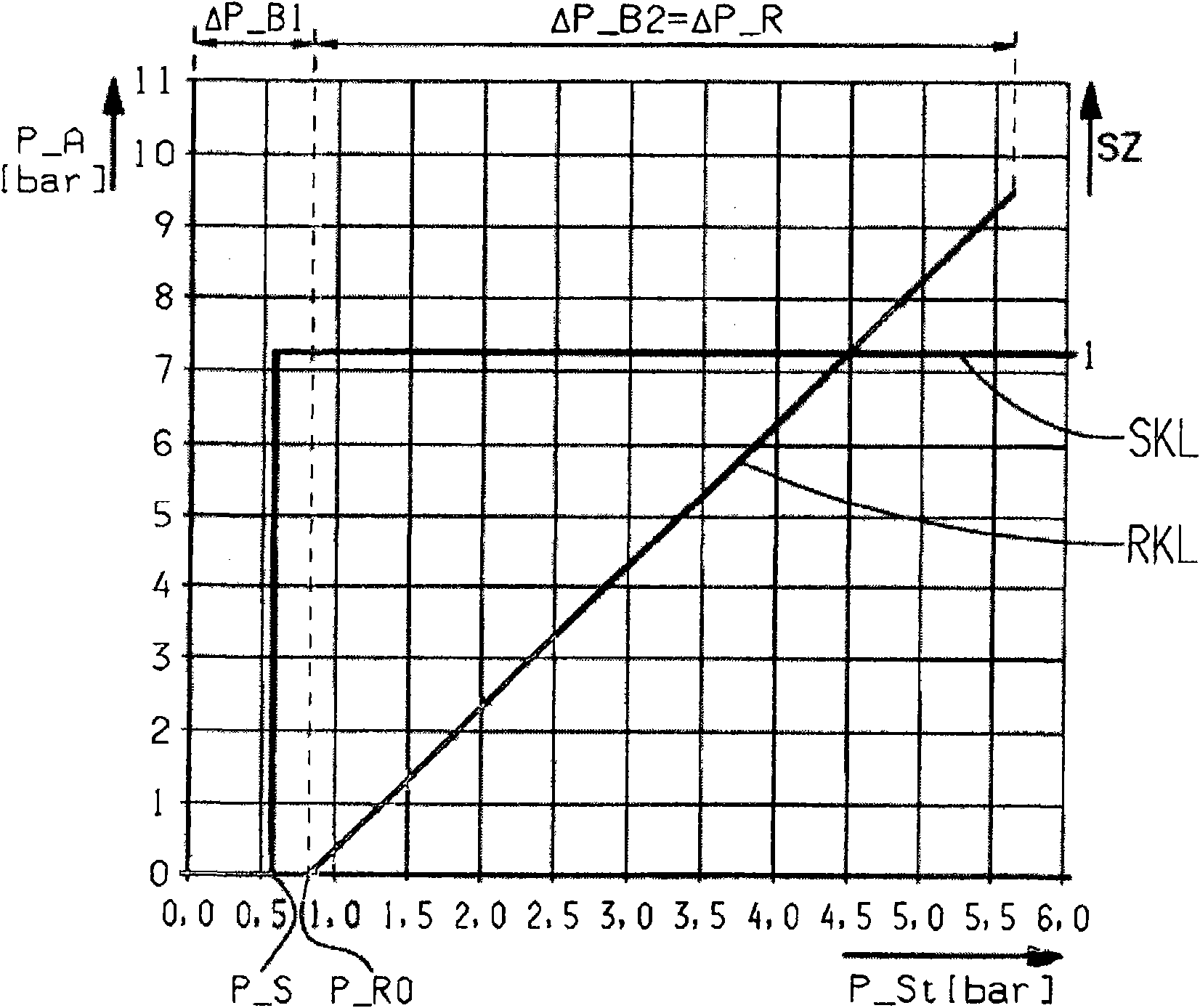

[0036] Corresponding to the embodiment of the control device described in DE 103 47 203 A1 with reference to FIG. 43 there, the known hydraulic control device 1.3 of the dual clutch transmission according to Figure 6 It has: four double-acting gear servo cylinders Z1-Z4, which each have two pressure chambers D1-D8 for the assigned gears G1-G7 and R to engage and remove gears; two The pressure-controlled gear adjustment valves GV1, GV2 are used to adjust the working pressure in two of the pressure chambers D1-D8; one has a pressure-controlled sub-transmission selector valve TWV and two pressure-controlled cylinder selector valves ZWV1, ZWV2 The multi-way mechanism 202, the two cylinder selection valves ZWV1, ZWV2 are used to selectively distribute the two gear adjustment valves GV1, GV2 to two of the eight pressure chambers D1-D8; The pre-control valves VV1 and VV2 of the valves 203 and 204 are used to regulate the two gear adjustment valves GV1 and GV2; Select valves TWV, ZW...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com