Connecting element for low-temperature applications, compressor for operation in the low-temperature range

A technology for connecting components and low-temperature applications, which can be used in the direction of connecting components, mechanical equipment, threaded fasteners, etc., and can solve problems such as low tensile strength dimensions, and achieve the effects of size-saving design, small space expansion, and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

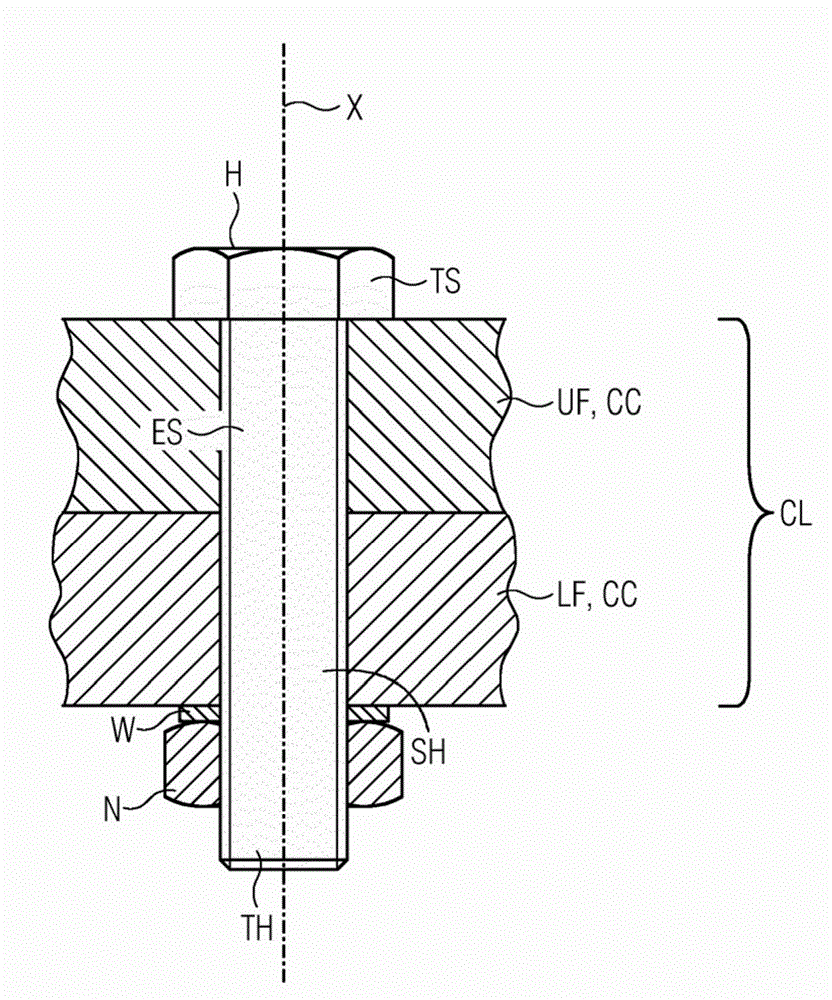

[0026] figure 1 A schematic cross-section is shown in the region of the junction of a turbocompressor not shown in detail for cryogenic applications. The turbocompressor has a housing CC with a horizontal joint SP which involves an upper housing half (the upper housing flange UF is shown in the drawing) and a lower housing half (The lower housing flange LF is shown in the drawing). The two housing halves or flanges UF, LF are held together by means of joining screws SH, one of which is shown in the drawing. The engaging screw SH extends along the longitudinal axis X and has a head H at its upper end with a wrench flat TS for accommodating a tool. The expansion shaft ES of the screw SH extends along the clamping length CL as far as the thread section TH, which terminates at the second end. A nut N is screwed onto the threaded section TH, which clamps together with the screw SH the two flanges LF, UF in the region of the clamping length CL with the washer W inserted in betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com