Universal bed insert constructed from an air cushion incorporating an airtight valve and method for its production

A technology for inserts and air cushions, used in tire inflation valves, mattresses, applications, etc., to solve problems such as not allowing low density and not guaranteeing dynamic operation of the insert or cushion, low compressive stress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

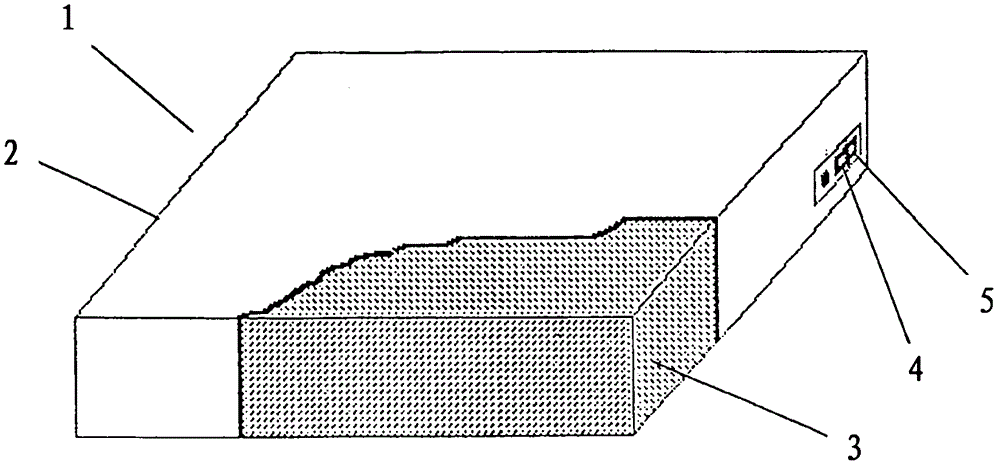

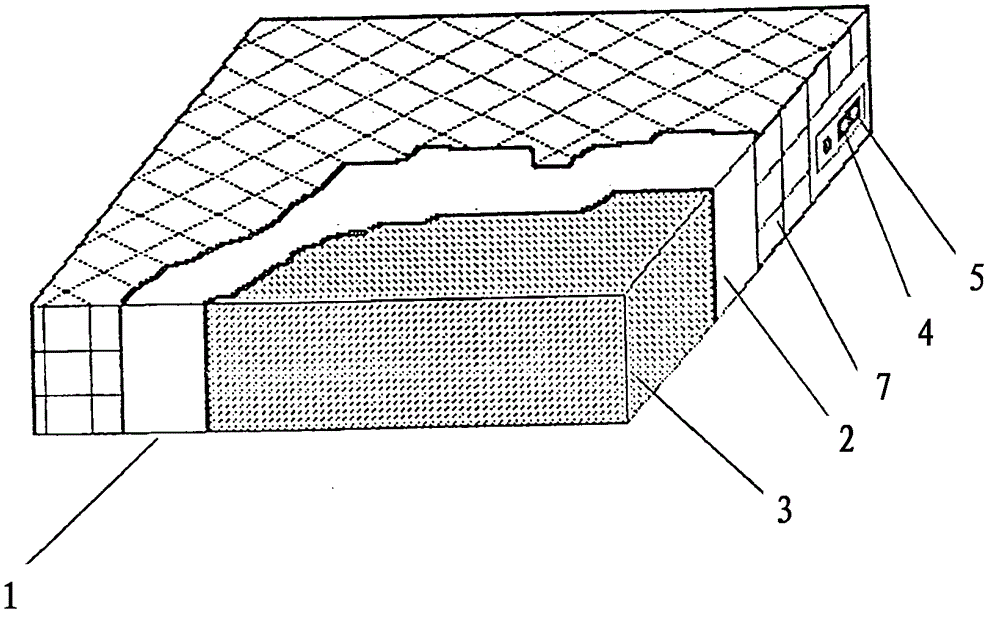

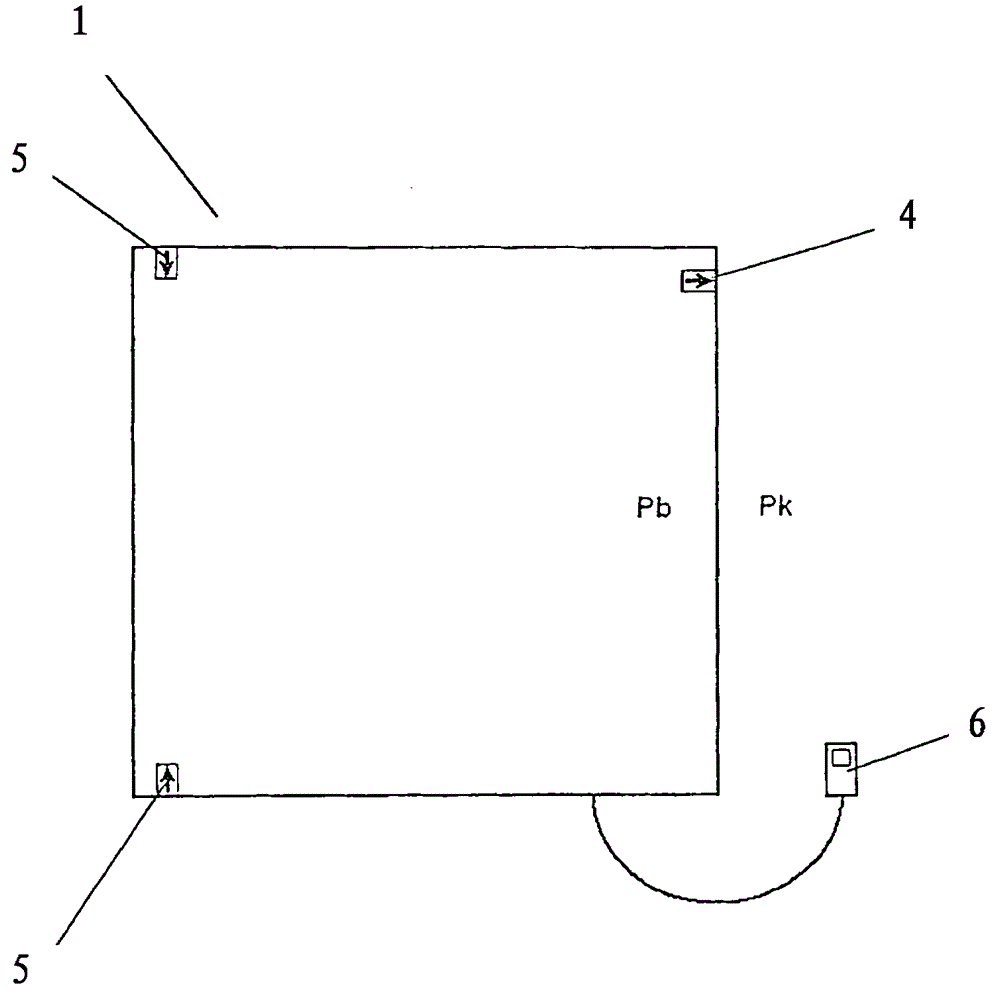

[0039] figure 1 The most common realization of the insert 1 according to the invention is shown partially broken. In this figure, an insert 1 can be seen comprising an air cushion 2 and a flexible sponge 3 of open cellular structure in the interior of the air cushion 2 . In the insert 1 , the regulating valve 4 and the non-return valve 5 are also connected in an airtight manner to the airtight covering of the air cushion 2 . The regulating valve 4 and the non-return valve 5 are fixed to the airtight covering of the air cushion 2 in a gas-tight manner, preferably by plastic welding.

[0040] Both the regulator valve 4 and the check valve 5 allow air to flow in one direction only. During loading, the air in the insert 1 leaves the interior of the insert 1 through the regulating valve 4 until the desired comfort position caused by the load 12 is achieved and at the same time a pressure equilibrium corresponding to the internal pressure set by the regulating valve 4 is achieved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com