High-pressure discharge lamp and light irradiation device

A technology for high-pressure discharge lamps and discharge tubes, which is applied in the manufacture of parts, ships or lead wires of gas discharge lamps, etc., can solve the problems of difficulty in forming a hollow layer 85, individual differences, and inability to obtain stable output effectively.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

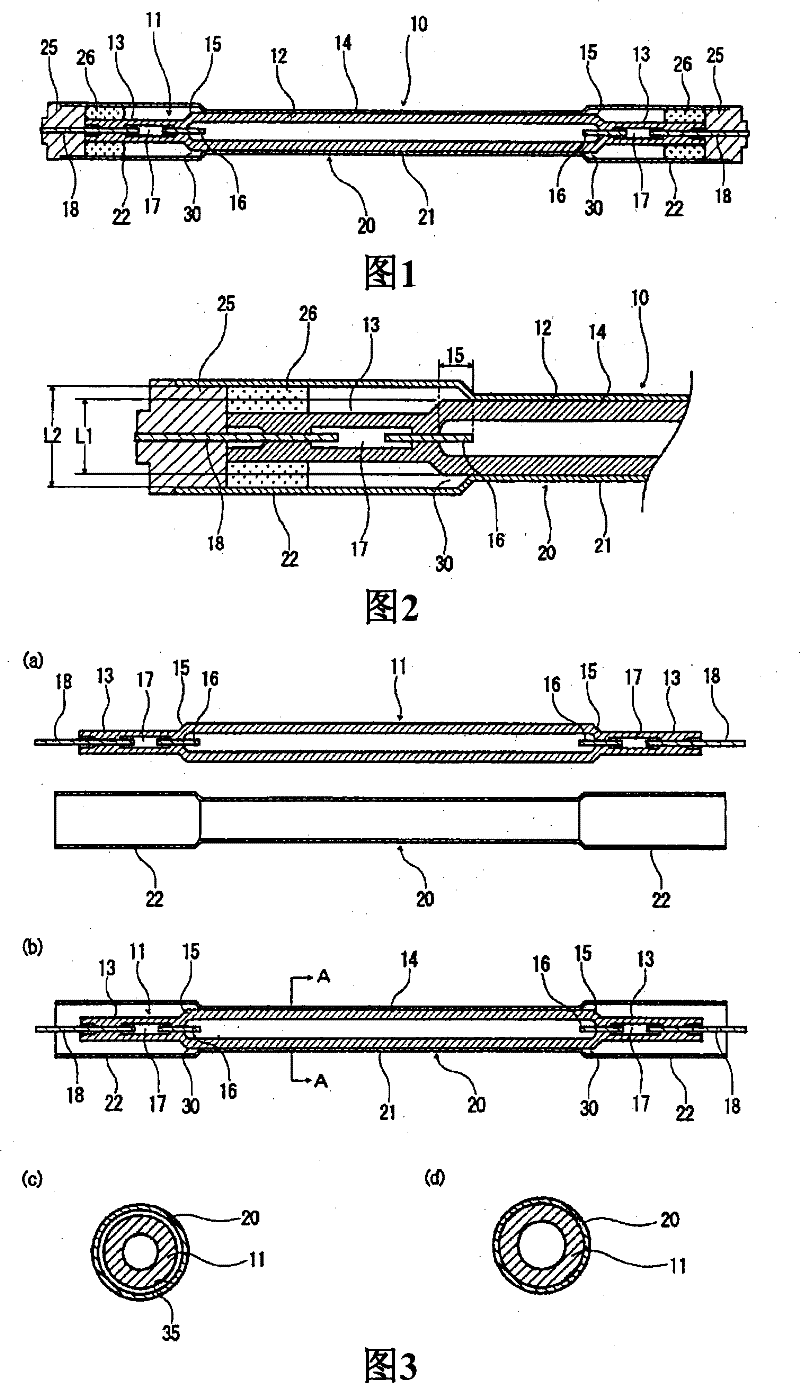

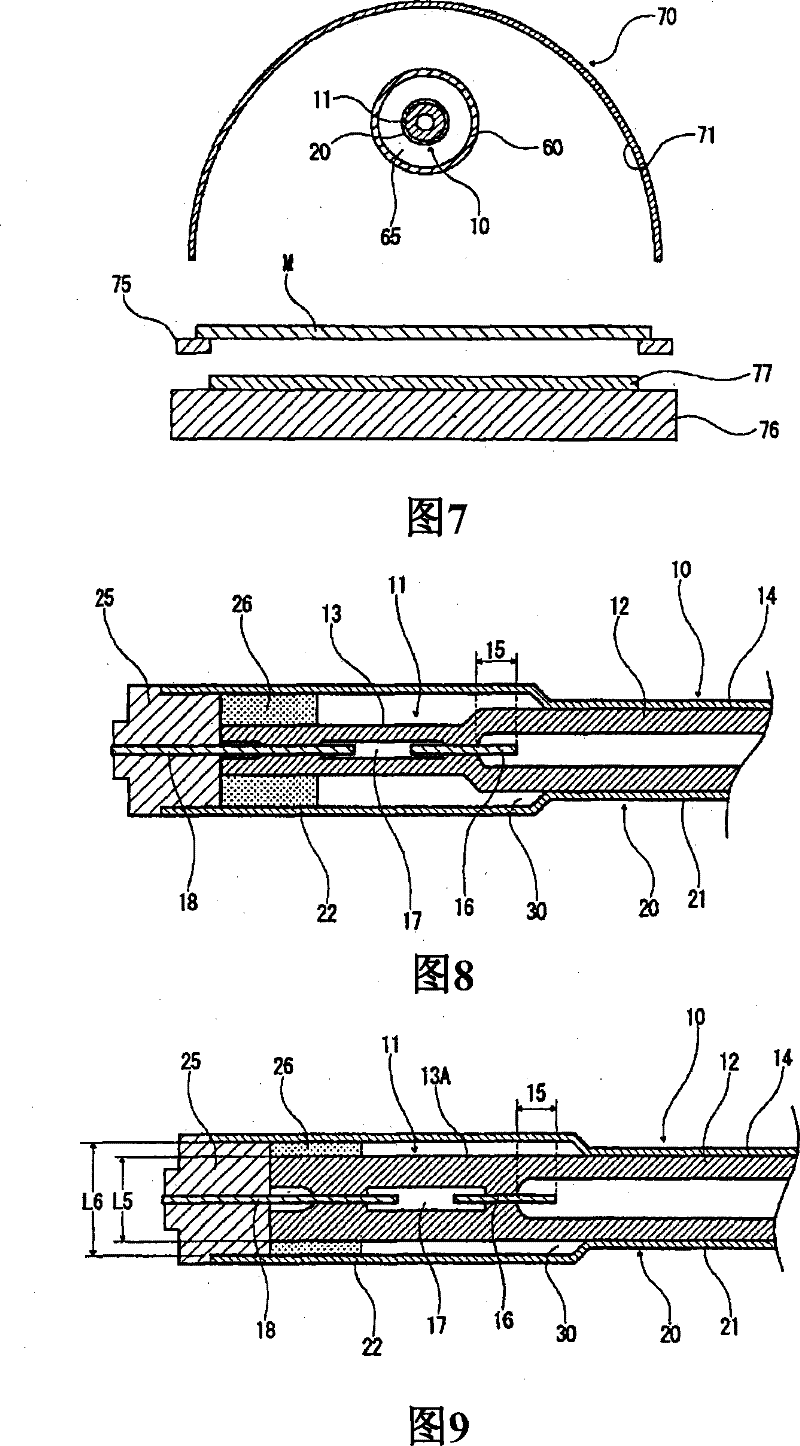

[0037] The high-pressure discharge lamp according to the first embodiment is configured by adopting a specific structure as the outer tube so that a gap extending over the entire circumference is formed between the outer peripheral surface of the portion around the electrodes of the discharge tube and the inner peripheral surface of the outer tube. Hereinafter, the configuration of the high-pressure discharge lamp according to the first embodiment will be specifically described.

[0038] figure 1 It is an explanatory cross-sectional view showing an outline of the configuration of an example of the high-pressure discharge lamp according to the first embodiment of the present invention. figure 2 yes means figure 1 An enlarged sectional view of the main part of the high pressure discharge lamp shown.

[0039] The high-pressure discharge lamp 10 is composed of the following two parts: a rod-shaped discharge tube 11 as a whole, sealed at both ends, and inside a straight tube-s...

no. 2 approach

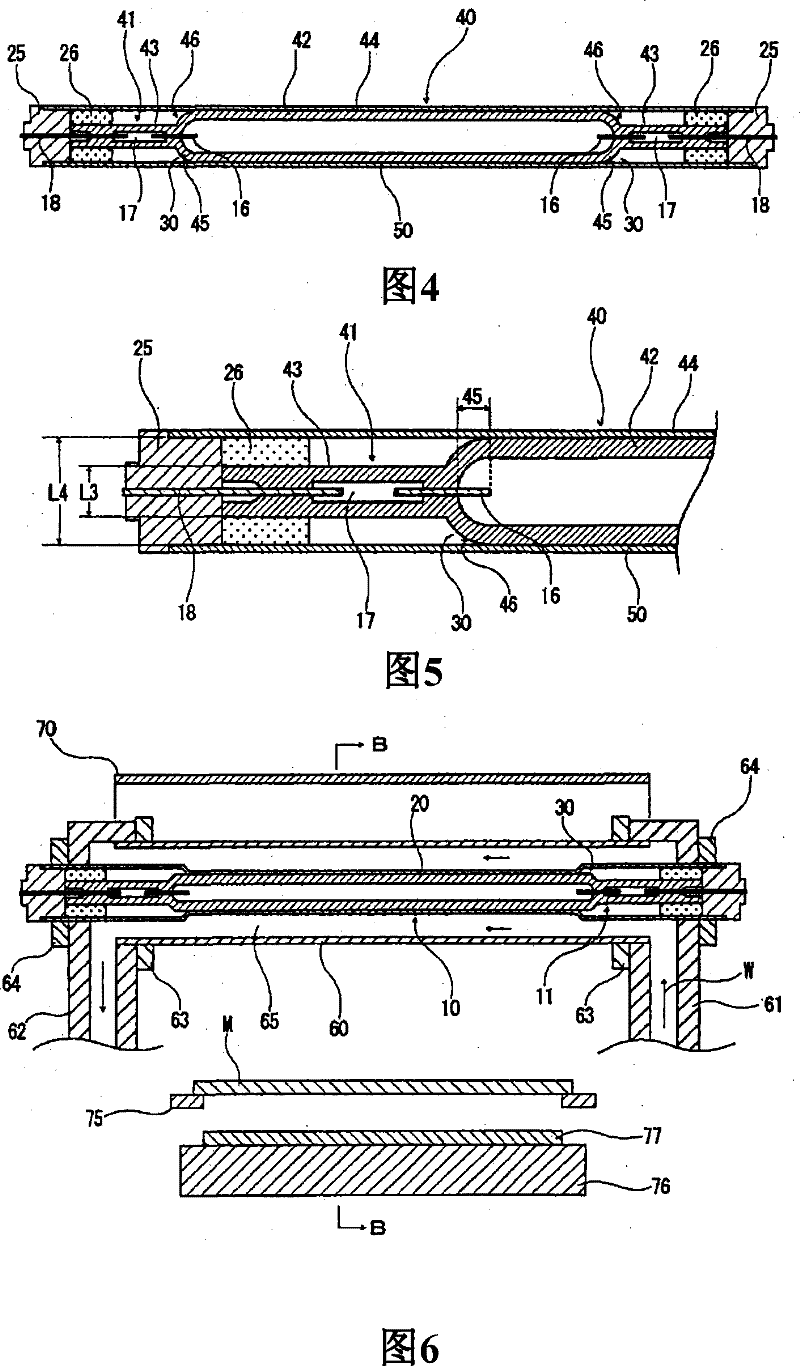

[0068] The high-pressure discharge lamp related to the second embodiment uses, for example, a straight tube whose inner diameter is uniform in the axial direction as the outer tube, and uses a rod-like material whose diameter is smaller than that of the central part located around the electrode and is located around the electrode. A gap extending over the entire circumference is formed between at least the outer peripheral surface of the supercooling preventing portion of the discharge tube and the inner peripheral surface of the outer tube. Hereinafter, the structure of the high-pressure discharge lamp concerning this 2nd Embodiment is demonstrated concretely.

[0069] Figure 4 It is an explanatory cross-sectional view showing an outline of the configuration of an example of the high-pressure discharge lamp according to the second embodiment of the present invention. Figure 5 yes means Figure 4 An enlarged sectional view of the main part of the high pressure discharge la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com