Hand machine tool with a vibration damped rounded handle

A technology for hand-held machine tools and handles, applied in the field of hammer drills and/or impact hammers, which can solve the problems of increased number of components, increased component inventory costs, and increased assembly costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

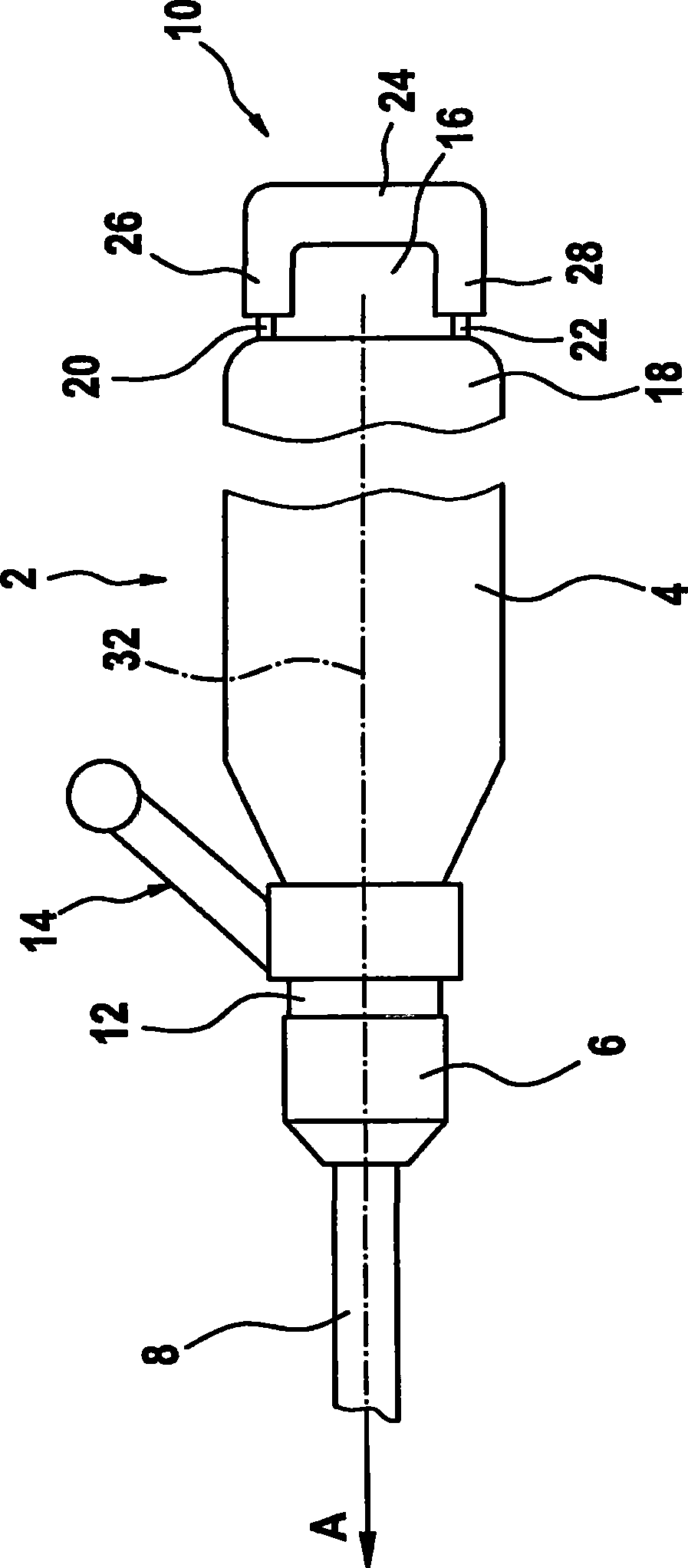

[0018] figure 1 A hand-held power tool 2 in the form of a hammer drill or percussion hammer shown schematically in the figure basically consists of a housing 4, a tool holder 6 for receiving a tool 8 and a drive unit (not shown) surrounded by the housing 4 ) composition, the drive device is used to drive the tool 8 mounted in the tool holder 6 in rotation and impact.

[0019] In a known manner, the drive device consists of an electric drive motor and a percussion mechanism also driven by the drive motor, which drives the tool 6 in rotation via a reduction gear or shift gear, by means of which the percussion mechanism can be used to Impact forces in the working direction A of the machine tool 2 act on the tool 8 in the tool holder 6 .

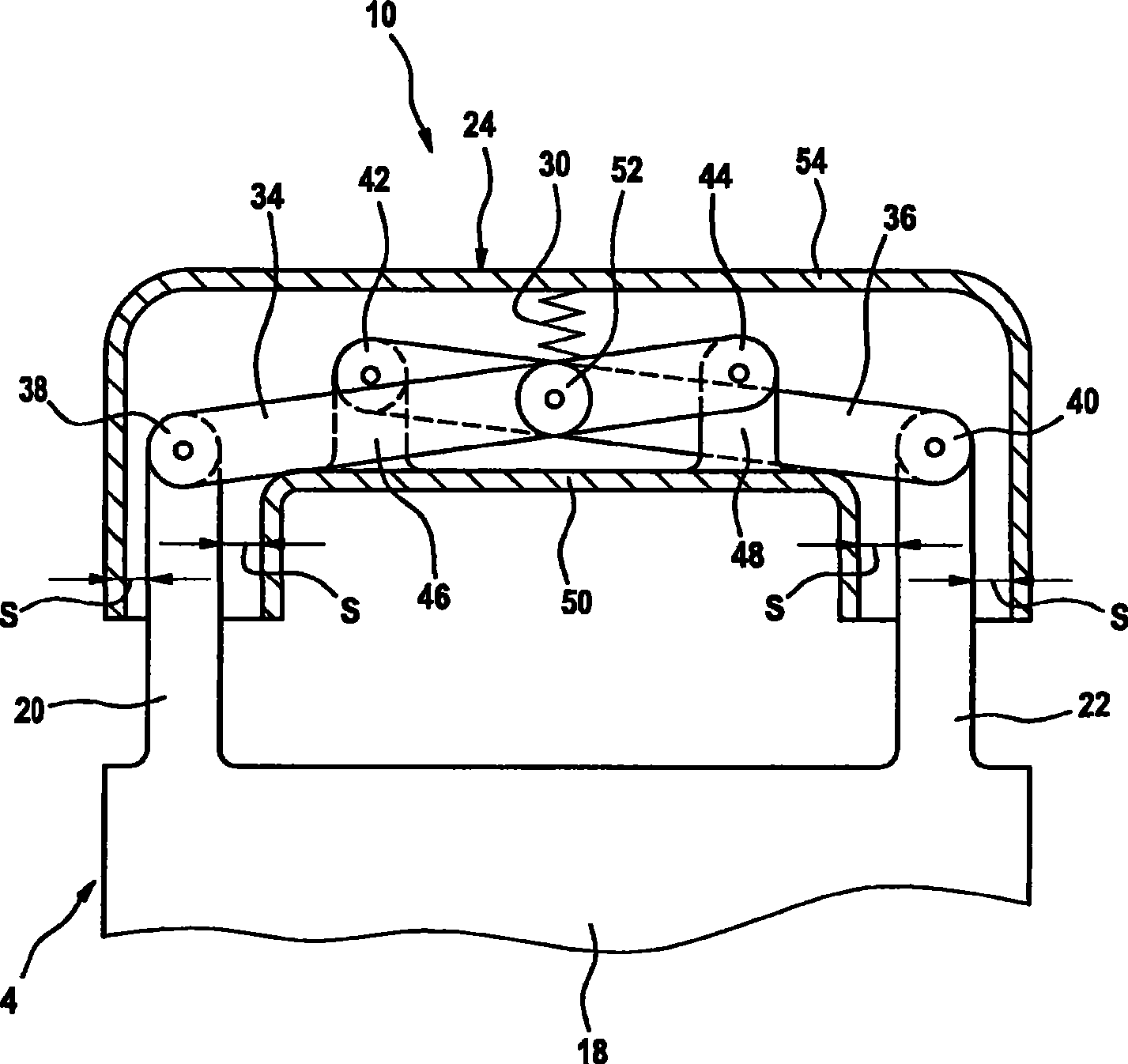

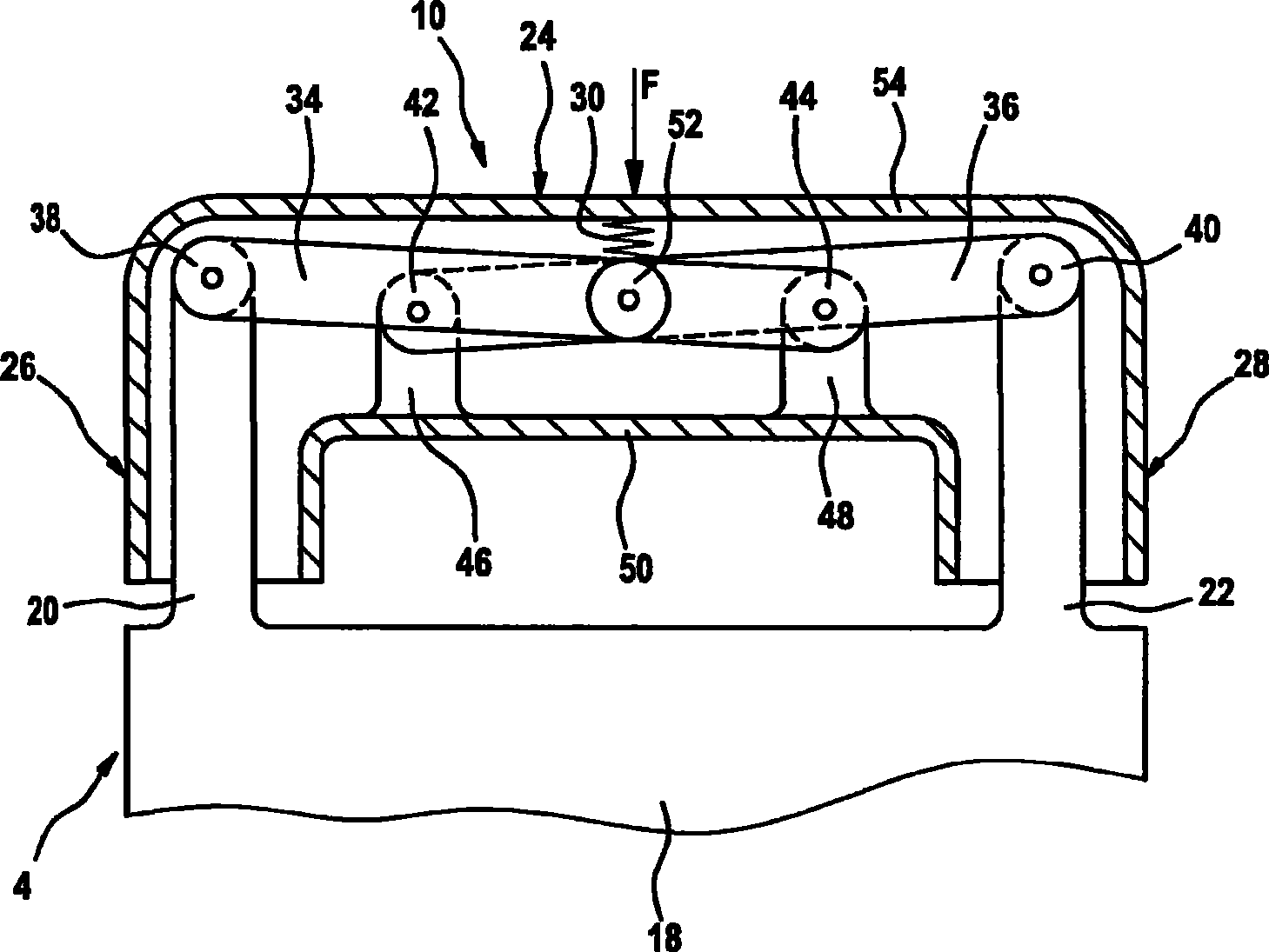

[0020] On its rear end facing away from the tool holder 6, the housing 4 is provided with an arcuate handle 10, which is connected to an additional handle detachably mounted on the housing 4 at 12 near the tool holder 6. 14 together are used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com