Linear compressor and gas thrust bearing therefor

A technology of thrust bearings and compressors, applied in the direction of linear motion bearings, bearings, shafts and bearings, which can solve problems such as increased operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

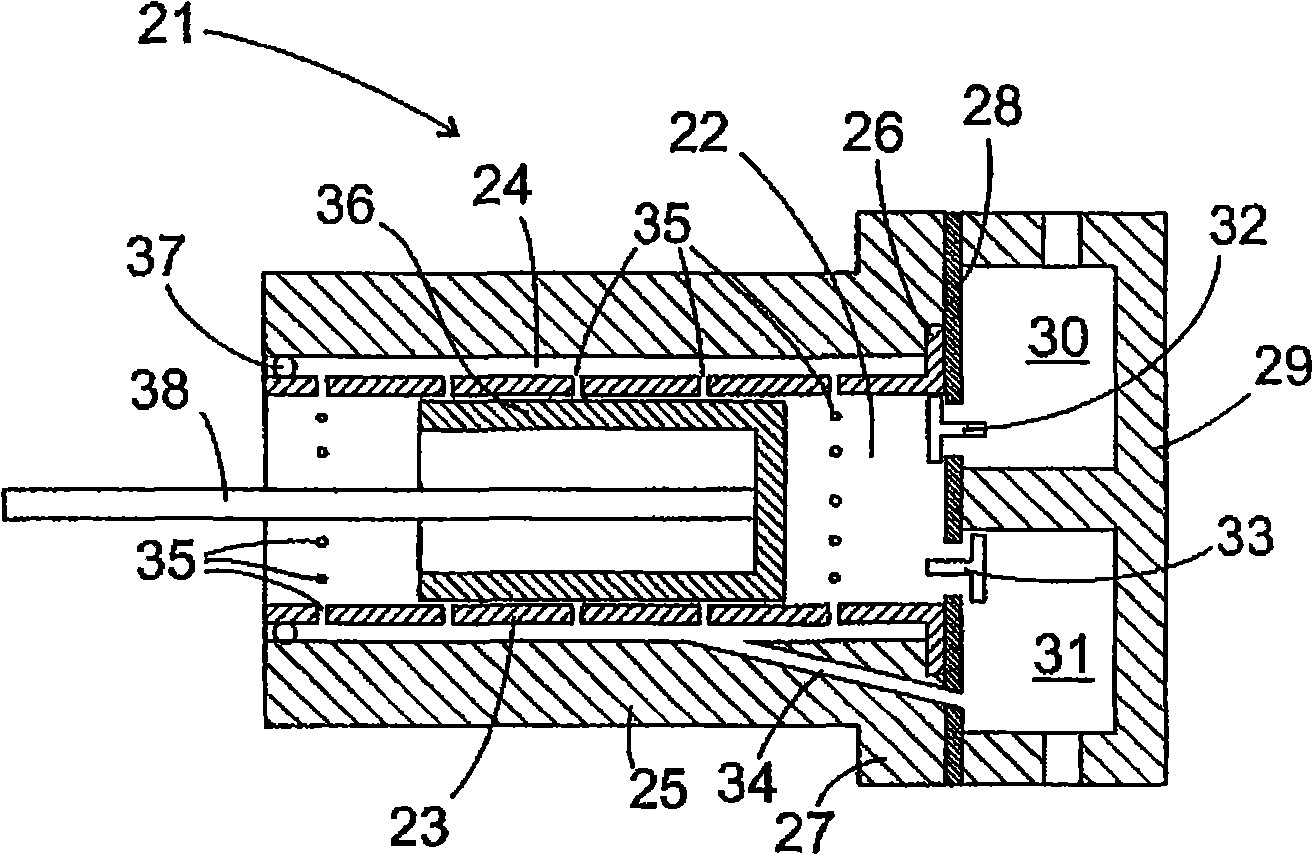

[0018] exist figure 1 The compressor shown in includes a housing 21 having a hollow cylindrical bearing bush 23 delimiting a working volume 22 . The bearing bushing 23 is surrounded by a cavity 24 which in turn is defined by a generally cylindrical housing portion 25 . The bearing bush 23 and the housing part 25 respectively extend around one end thereof with an annular flange 26 or 27, wherein the flange 26 of the bearing bush 23 engages on one side with a cutout defined by the housing part 25 and on the other. One side engages with the spring piece 28, while the bearing bushing 23 is fixed to the housing part 25, and the spring piece 28 is rigidly connected with the flange 27 of the housing part 25 in any suitable manner, and forms an air connection with the spring piece 28. Tight seal. At the end remote from the flanges 27 , 28 the cavity 24 is sealed by an O-ring 37 clamped between the bearing bushing 23 and the housing part 25 .

[0019] A cover 29 attached to the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com