Outer rotor type motor and outdoor unit having the same

A technology of external rotor and motor, which is applied in the field of outdoor units of air conditioners, and can solve problems such as inability to rotate the rotor and damage to the external rotor motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0049] In the outer rotor type motor according to the first embodiment, the bracket is integrally formed on the outer circumferential surface of the lower cover. However, in the outer rotor type motor according to the second embodiment, an additional support bracket is assembled to the outer circumferential surface of the lower cover.

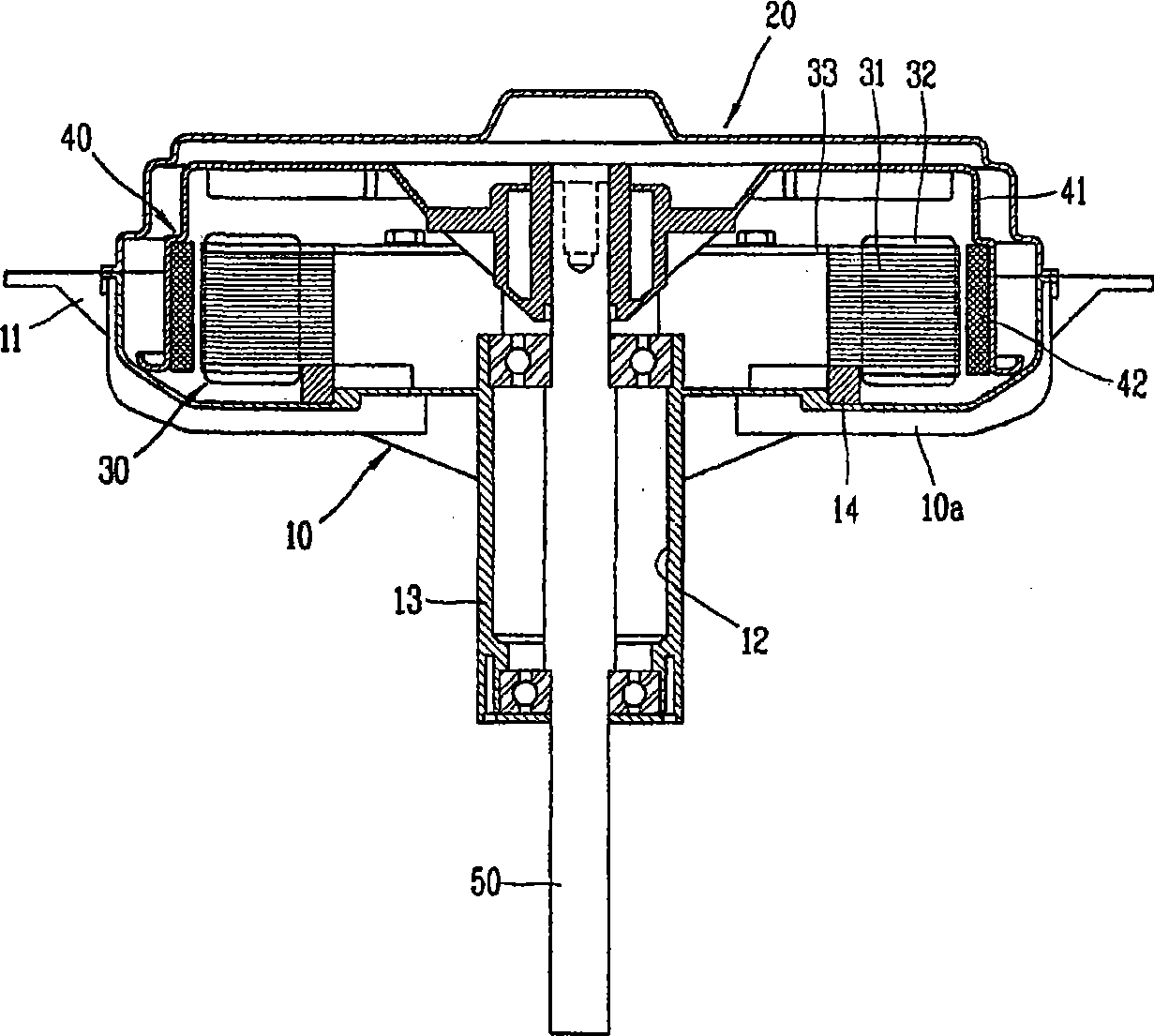

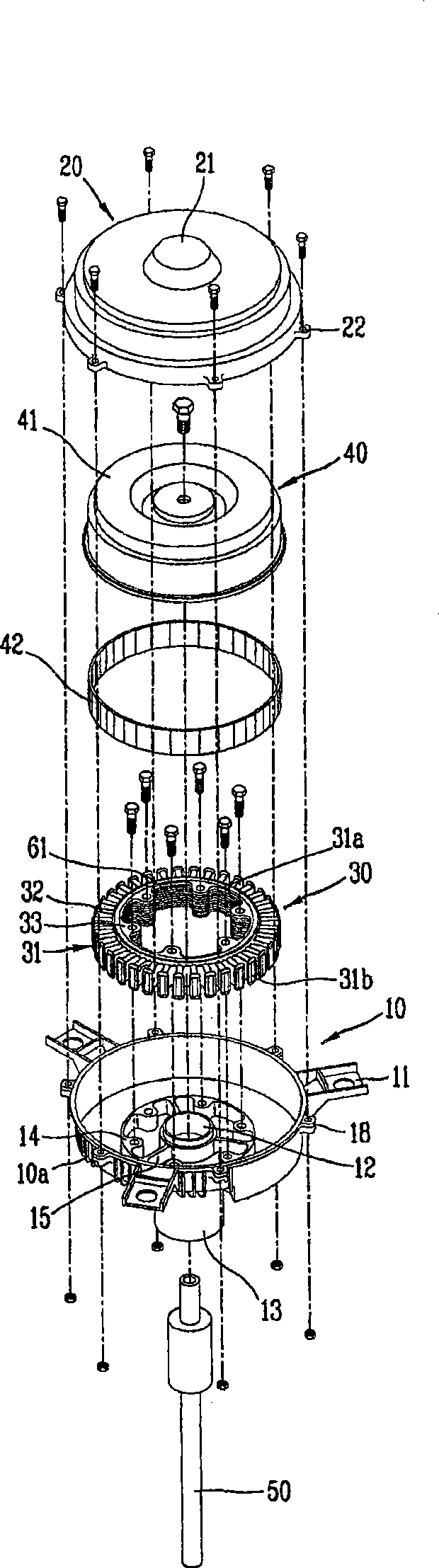

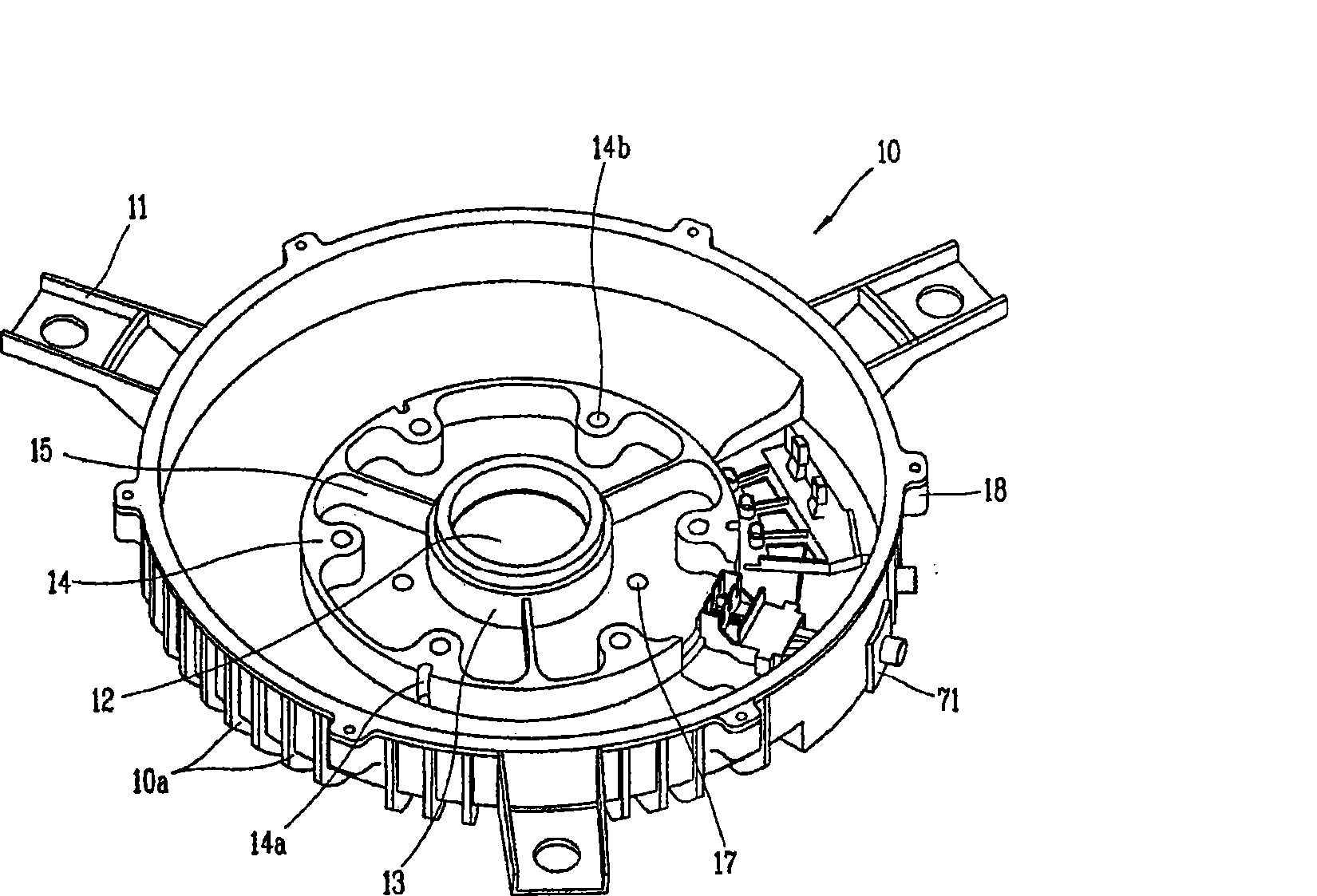

[0050] as in Figure 7 and Figure 8 As shown in , the outer rotor type motor according to the second embodiment includes: a support bracket fixed to a position where the outer rotor type motor is to be installed; a lower cover 10 coupled to the support bracket 70 and having an inner space; coupled to the lower cover 10 and close the upper cover 20 of the inner space of the lower cover 10; the stator 30 fixedly installed in the inner space of the lower cover 10; the rotor 40 placed on the outer peripheral surface of the stator 30 in a rotatable manner; and coupled to the rotor 40 The center of the rotating shaft 50 thereby transmitting the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com