Detection method of thick beam structure damage based on guide wave

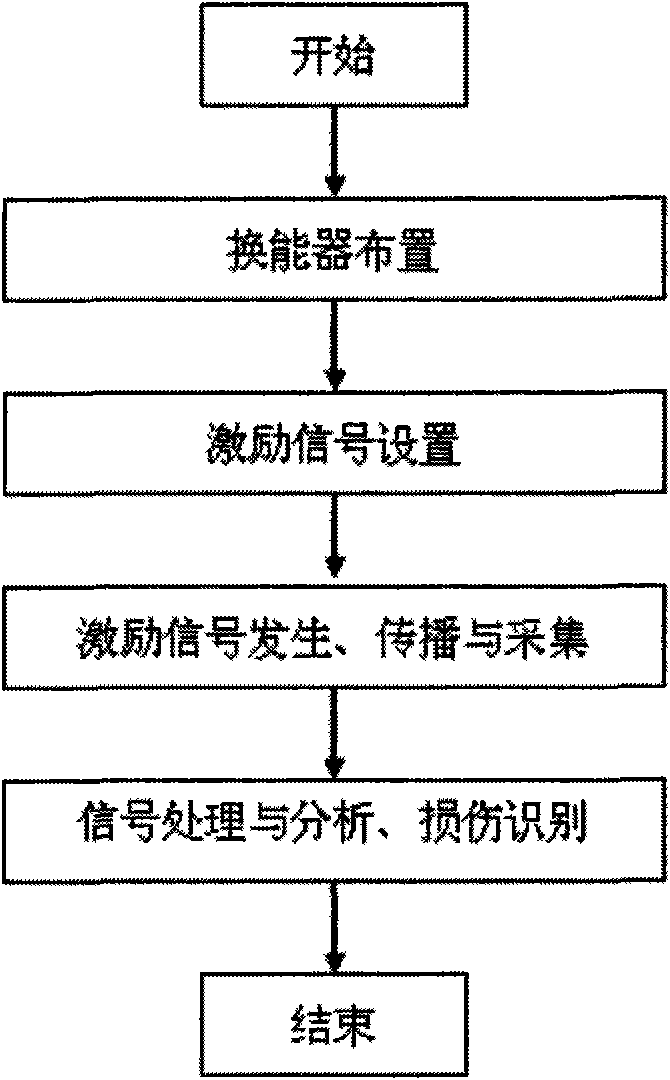

A technology of damage detection and beam structure, applied in the field of detection, can solve the problems of complex Lamb waves, increase the complexity of signal processing and analysis, and achieve the effect of realizing damage monitoring and simple operation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below with reference to the drawings: this embodiment is implemented on the premise of the technical solution of the invention, and detailed implementation modes and specific operation procedures are given, but the protection scope of the present invention is not limited to the following embodiments .

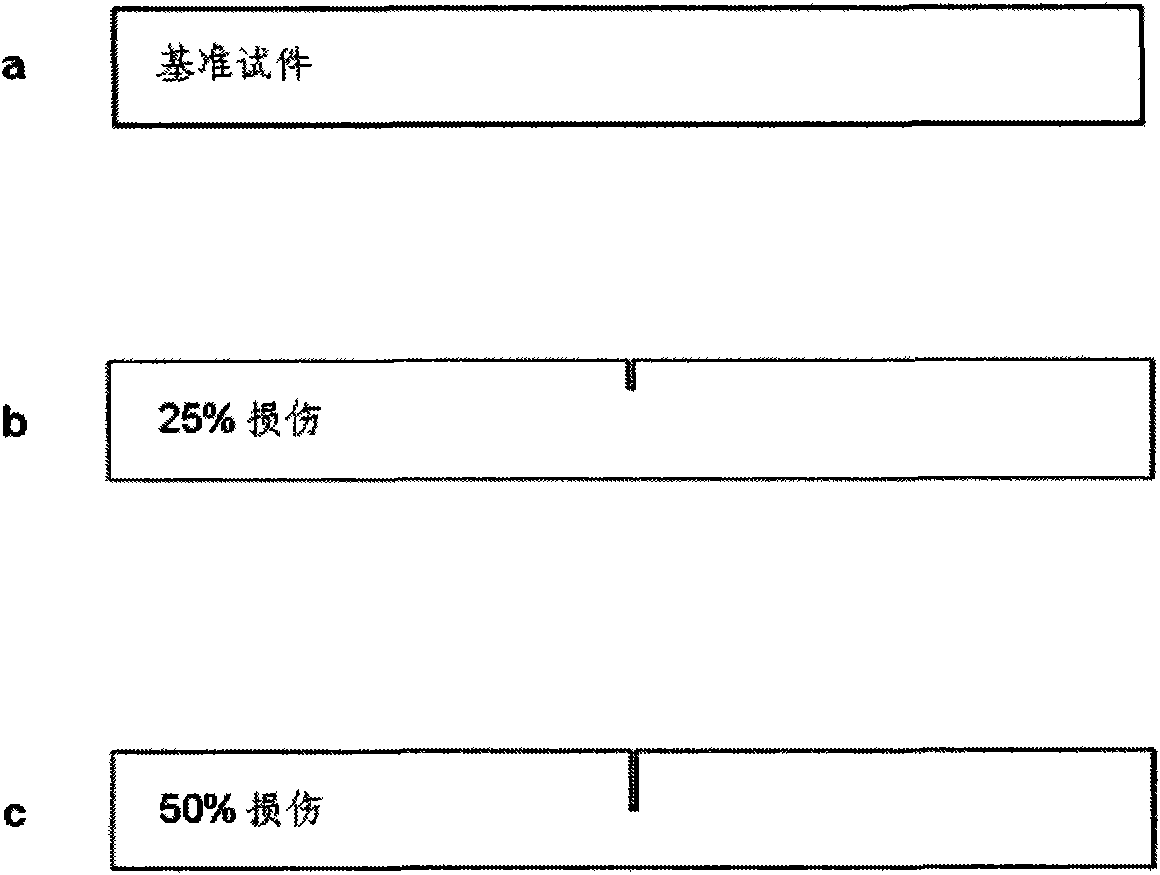

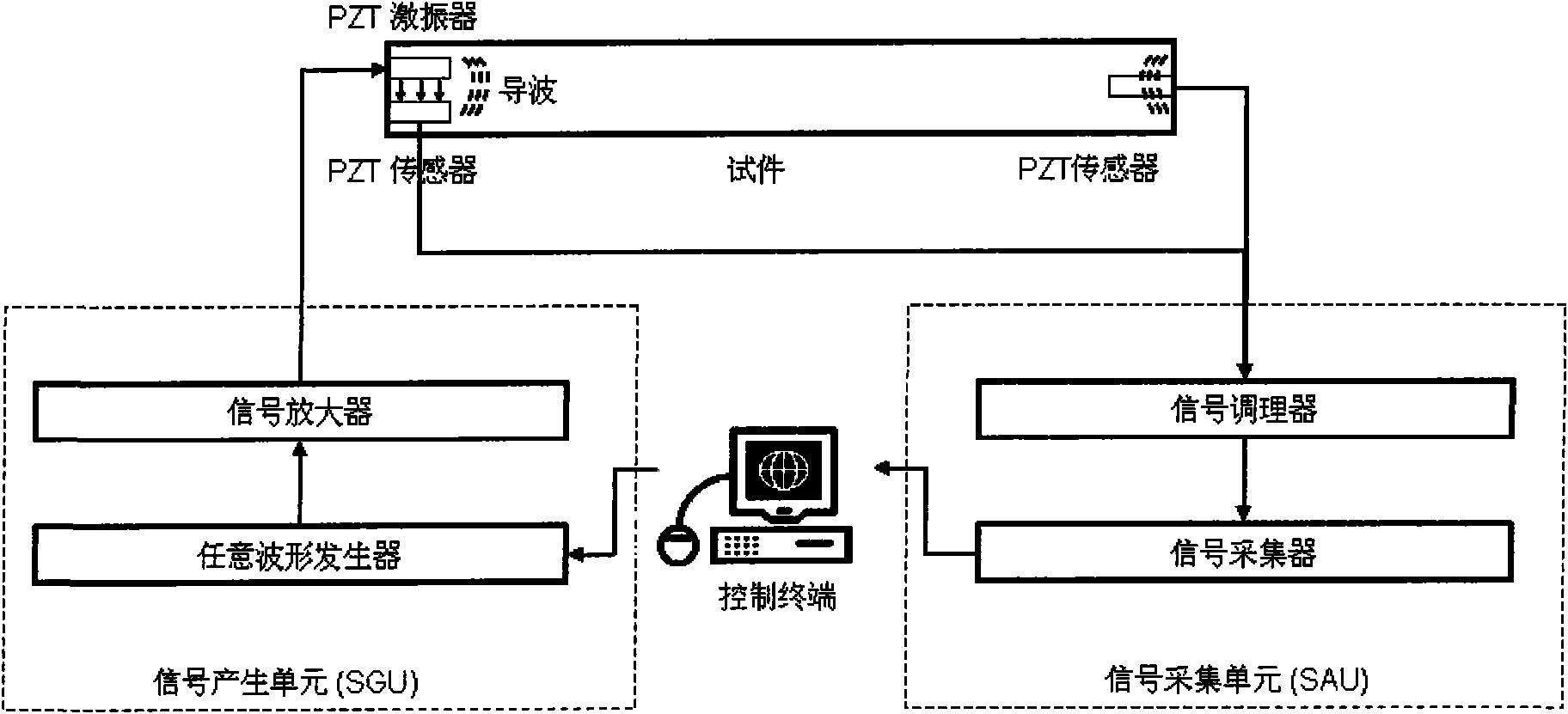

[0031] This embodiment adopts such as figure 2 Specimen shown. The test piece is a stainless steel beam with a size of 300mm×34mm×25mm. In order to demonstrate the principle and effect of the test, a total of three specimens were made, one of which was the reference specimen (without damage), and the other two specimens had incisions with different depths in the middle of the specimen, and the damage degree was 25 respectively. % And 50% (definition of damage degree: ratio h / d of notch depth h to beam thickness d). Three PZT transducers are arranged for each test piece, one is a vibration exciter, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com