Piezoelectric motor

A technology of piezoelectric motors and motor shafts, applied in electrical components, piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, etc., can solve problems affecting motor output, occupation, large space, etc. To achieve the effect of compact structure and increased output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical problems to be solved, technical solutions and beneficial effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

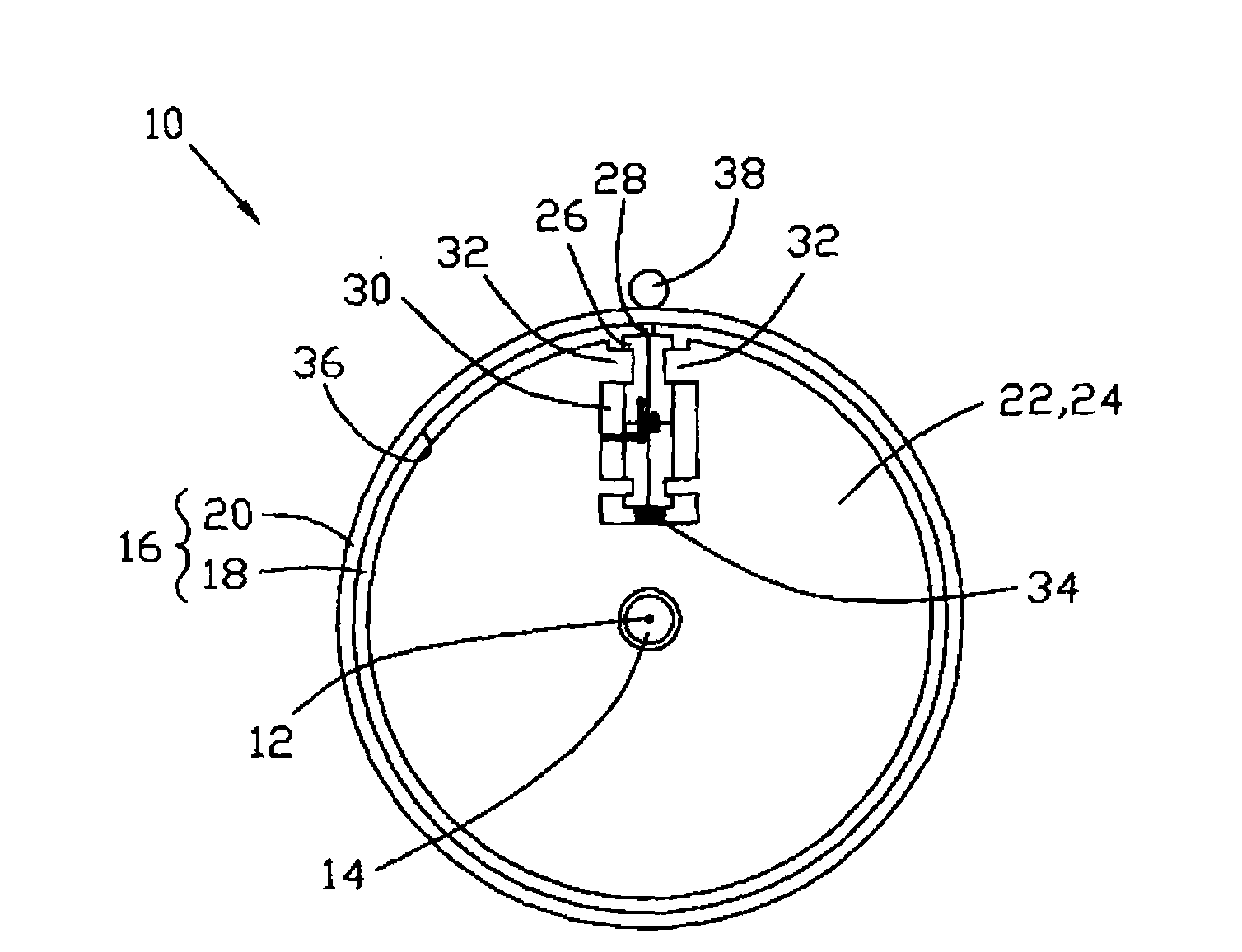

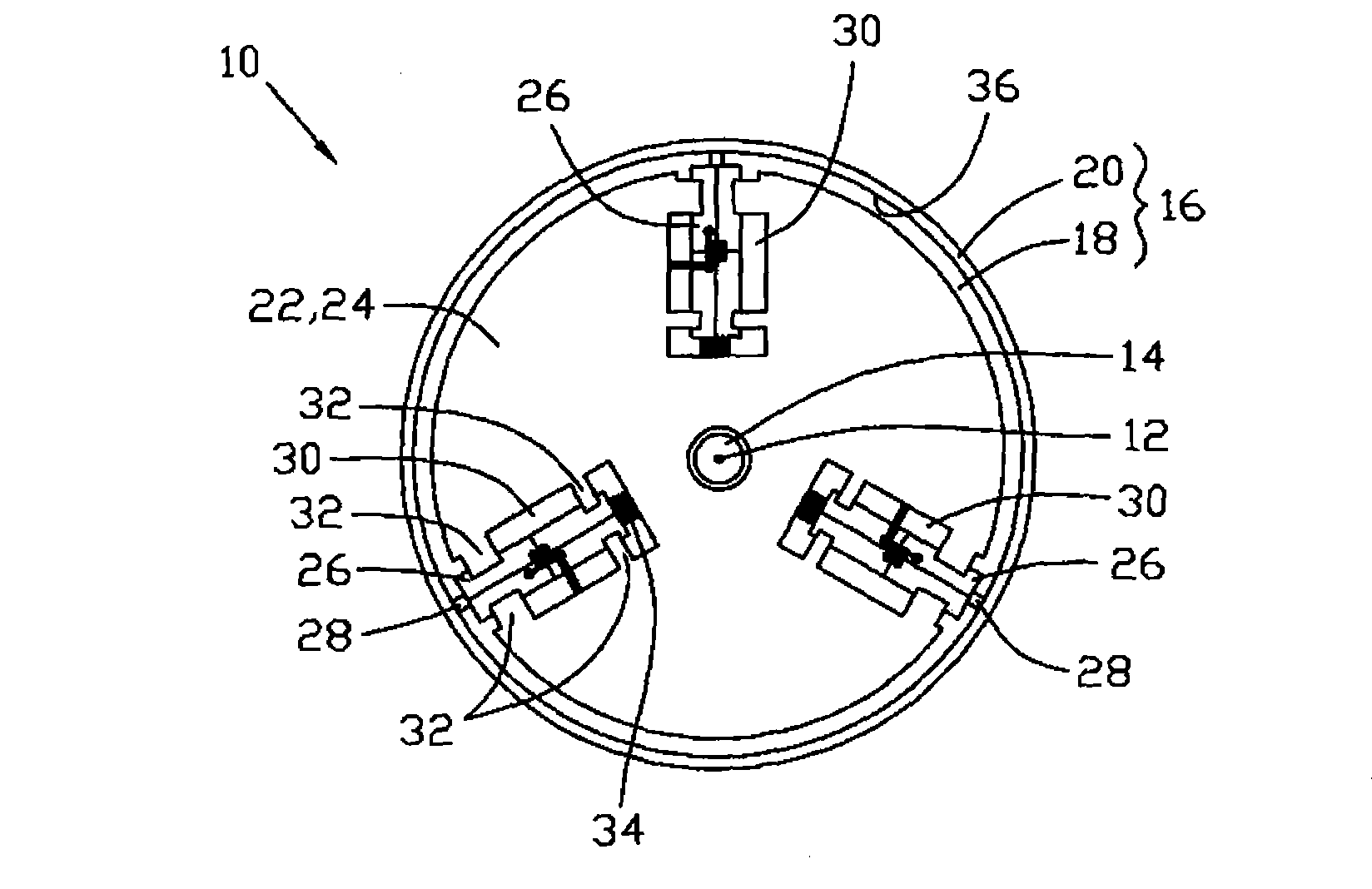

[0019] figure 1 Shown is a side view of a piezoelectric motor 10 perpendicular to the axis 12 provided by the embodiment of the present invention. A motor shaft 14 of piezoelectric motor 10 extends along axis 12 . The piezoelectric motor 10 includes a rotor 16 and a stator 22 . The rotor 16 is fixed on the motor shaft 14 and has a cup-shaped appearance. It includes a body 18 extending radially and a rotating body 20 extending axially from the outer edge of the body 18. A receiving space is formed between the body 18 and the rotating body 20 Between, the stator 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com