Rotor drive of an open-ended spinning apparatus

A driving device, free end technology, applied in the processing of textile materials, bearings, shafts, etc., can solve the problems of spinning rotor wear, uncoordinated adjustment characteristics, and increased implementation costs, and achieve the effect of reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

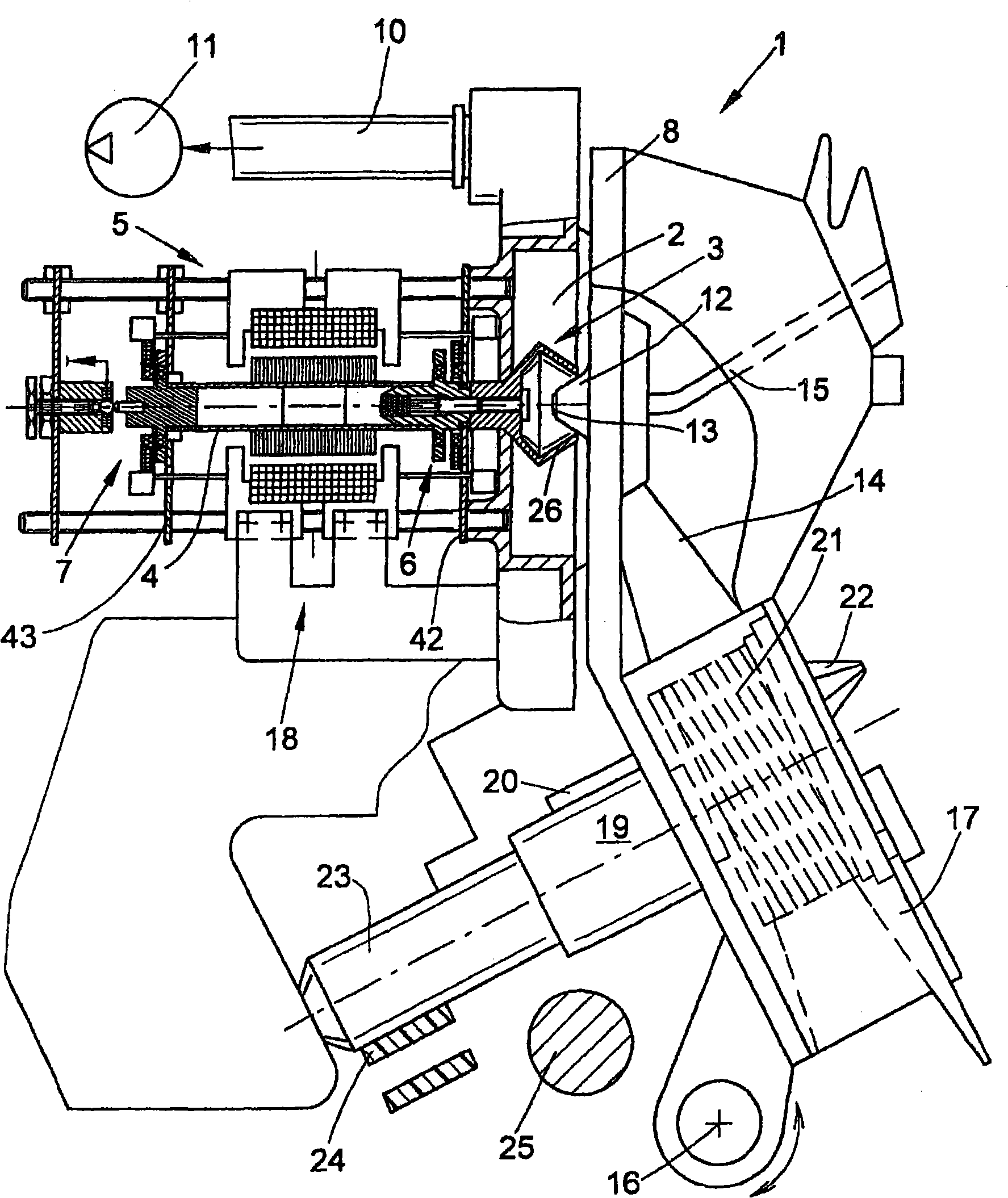

[0023] figure 1 An open-end spinning device 1 is shown, which is known in principle and has been described in detail, for example, in EP 0 972 868 A2.

[0024] Such an open-end spinning device 1 has a rotor housing 2 in which a spinning cup 26 of a spinning rotor 3 rotates at a high rotational speed.

[0025] Usually, the rotor housing 2 , which is itself open on the front, is closed during operation by a pivotally mounted cover element 8 , is connected via corresponding pneumatic lines 10 to a negative pressure source 11 which generates a rotor Necessary spinning negative pressure in housing 2.

[0026] As usual, a channel plate adapter 12 is arranged in the cover element 8 in a replaceable manner, the channel plate adapter 12 having the thread withdrawal mouth 13 and the mouth of the fiber guide channel 14 . The yarn withdrawal nozzle 13 is connected to the yarn withdrawal tube 15 as known. In addition, the opening roller housing 17 is also fixed on the cover element 8 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com