High-efficiency automatic wire connecting double-side socket

An automatic wiring, double-sided technology, applied in the direction of clamping/spring connection, etc., can solve the problems of poor wiring, poor contact, high cost, and achieve the effect of good quality, reduced production and assembly costs, and high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

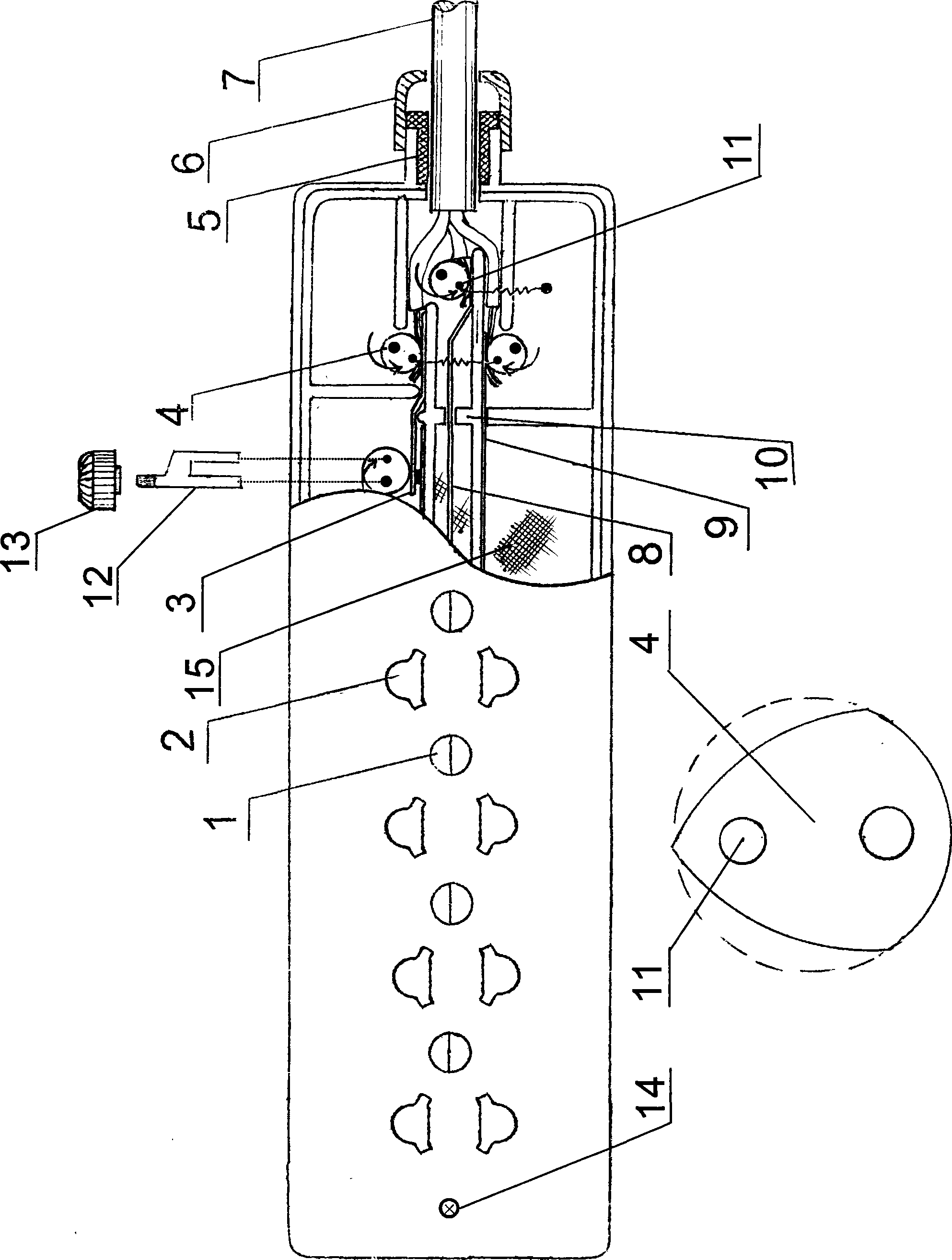

[0014] Referring to the accompanying drawings, the present invention includes a power supply copper plate (9), a cam (4), a switch fork (12), a rubber sleeve (5) and a tight hoop (6), and it is characterized in that one side of each of the three copper plates is provided Cam (4); another switch cam (4) is arranged on the other side of the copper plate (3), and two eyes on the switch cam (4) cooperate with the switch fork (12); the three wiring cams ( 4) A return spring eye (11) is respectively arranged on the opposite corners of the shaft eye, and the small spring pulls the return spring eye (11) so that the deflection of the cam (4) leans against the copper plate. One end of the rubber sleeve (5) is engaged with the wire sleeve at the wire entry, and the other end is provided with a tight hoop (6), which is tightened with the wire sleeve; the grounding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com