Release paper recovering device

A recycling device and release paper technology, which is applied in the directions of transportation and packaging, sending objects, and thin material handling, etc., can solve the problems of poor vacuum, sticking to the baffle 31 on the side wall of the recycling station 3, etc., and achieves the improvement of recycling efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

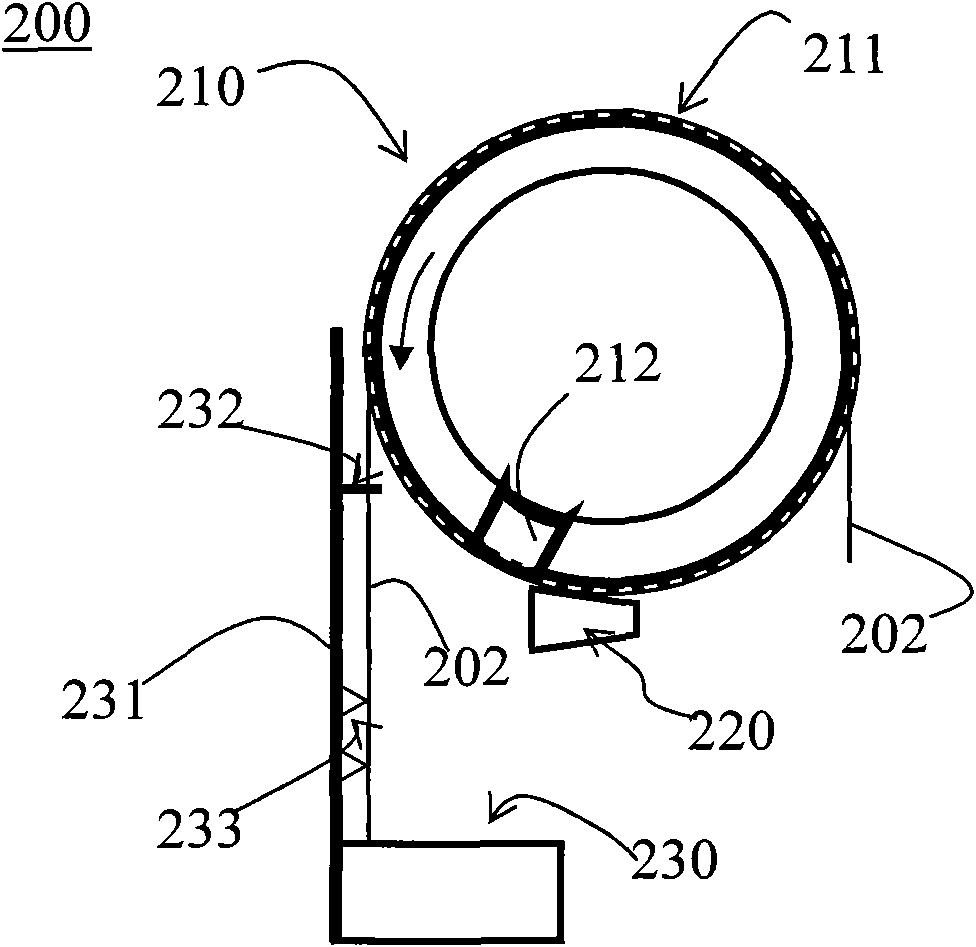

[0014] See image 3 , image 3 It is a schematic diagram of a release paper recovery device 200 according to an embodiment of the present invention. The release paper recycling device 200 includes a vacuum roller 210 and an anti-winding part 220 . The vacuum roller 210 includes a plurality of vacuum suction nozzles 211 and air jet holes 212. These vacuum suction nozzles 211 adsorb the release paper 202 on the vacuum roller 210. The vacuum roller 210 drives the release paper 202 to rotate. The air jet holes 212 are set On the obliquely lower side of the vacuum roller 210, and blow air outward. The anti-winding portion 220 is disposed on the side of the vacuum roller 210 to prevent the release paper 202 blown away from the vacuum roller 210 through the air injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com