Wedge-shaped chopper suitable for full-automatic bonding and processing method thereof

A fully automatic, wedge-shaped technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of pendulum wire, unqualified bonding solder joints, etc., to achieve the effect of large constraints and avoidance of pendulum wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

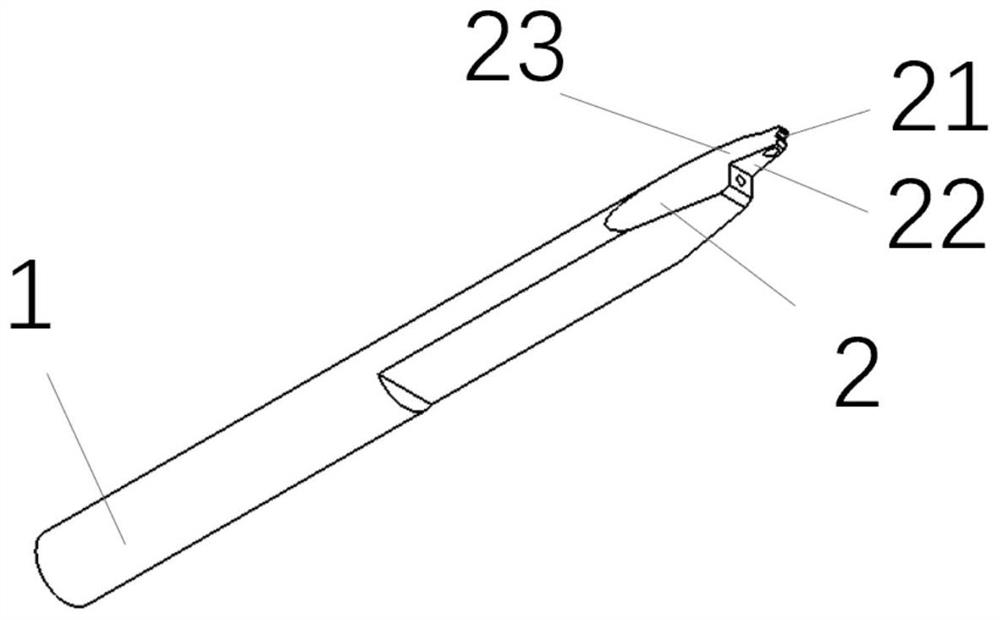

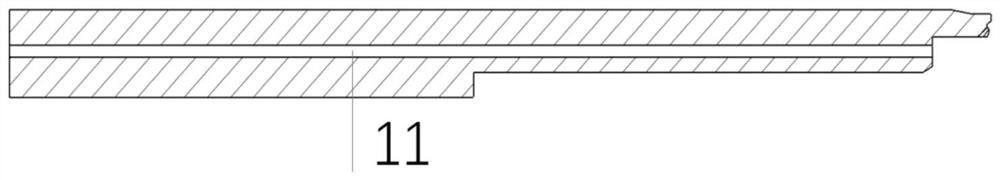

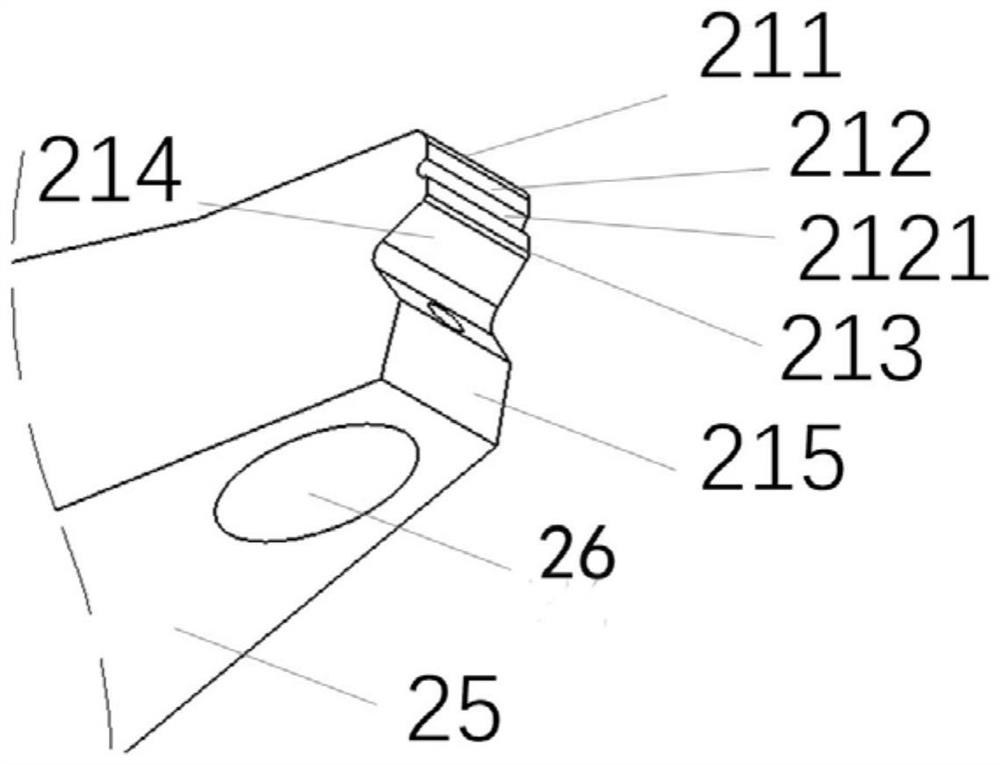

[0031] exist Figure 1-5 In the shown wedge-shaped capillary structure suitable for automatic bonding, the first chamfered surface 22 is provided with a second lead hole 26 extending to the groove 214, the second lead hole 26 is tapered, and the taper is 1°, The diameter of the small circle is 0.02mm, the cross section of the groove 2121 is an arc, the radius of the arc is 0.01mm, and the width is 0.01mm.

Embodiment 2

[0033] like Figure 1-5 In the shown wedge-shaped capillary structure suitable for automatic bonding, the first chamfered surface 22 is provided with a second lead hole 26 extending to the groove 214, and the second lead hole 26 is tapered with a taper of 10°, The diameter of the small circle is 0.05mm, the cross section of the groove 2121 is a trapezoid, the angle between the two waists of the trapezoid groove is 1°, and the length of the lower bottom is 0.01mm.

Embodiment 3

[0035] like Figure 1-5 In the wedge-shaped capillary structure shown for fully automatic bonding, the first chamfered surface 22 is provided with a second lead hole 26 extending to the groove 214, and the second lead hole 26 is tapered with a taper of 20°, The diameter of the small circle is 0.09mm, the cross-section of the groove 2121 is trapezoid, the angle between the two waists of the trapezoid groove is 120°, and the length of the lower bottom is 0.08mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com