Bending die

A technology of bending molds and bending blocks, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of low mold debugging efficiency and inconvenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

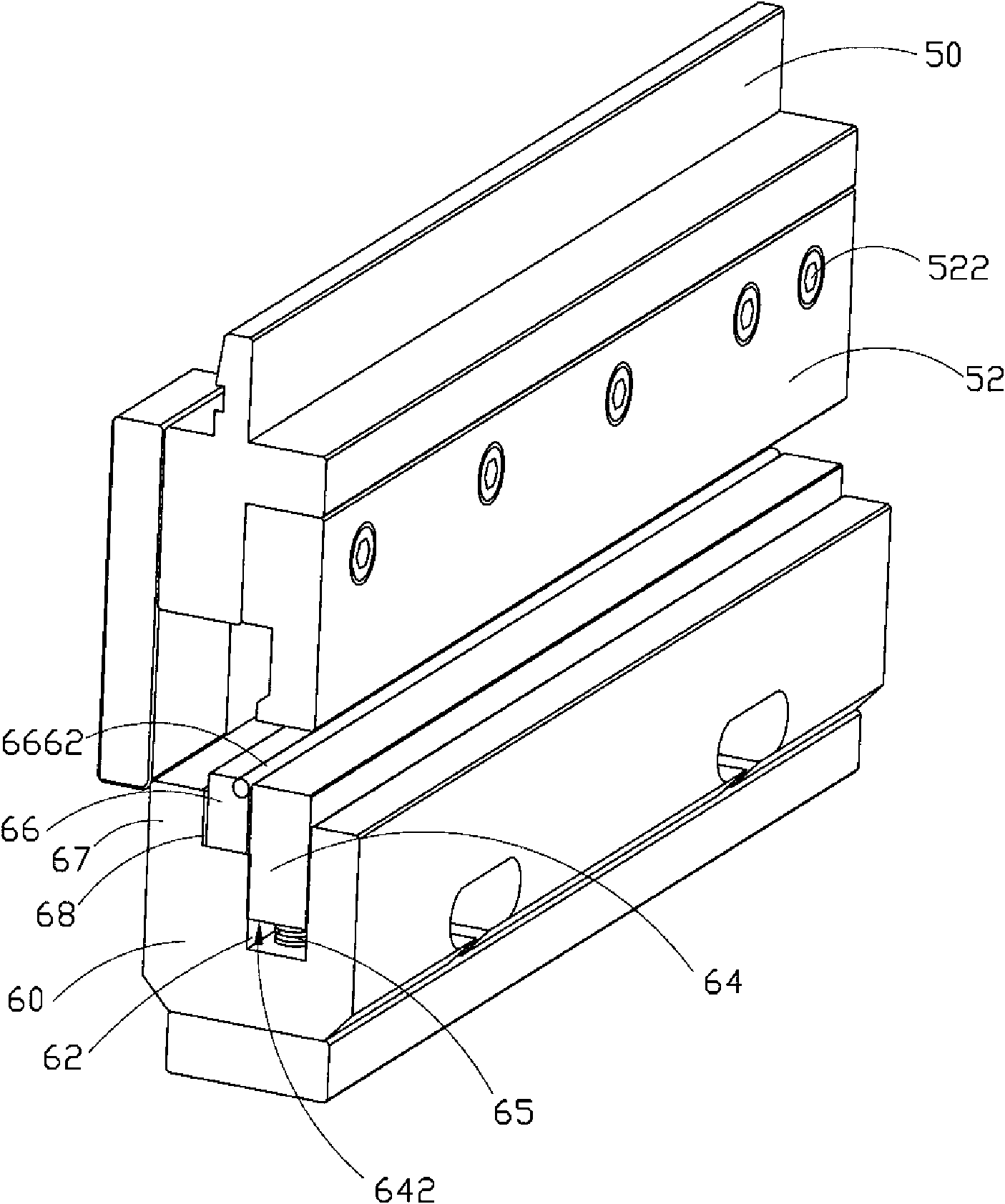

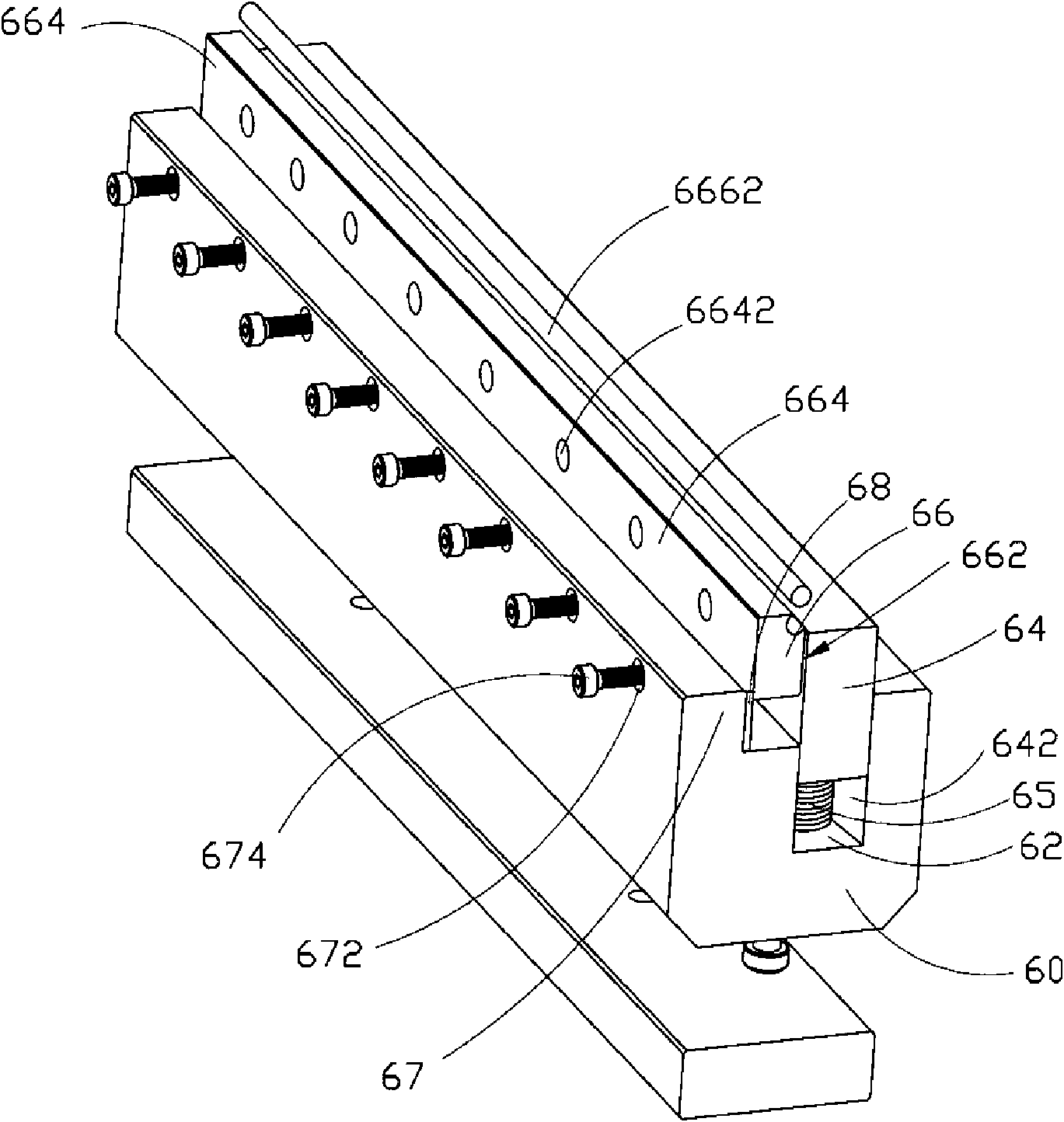

[0014] see figure 2 with image 3 , which shows a bending die in a preferred embodiment of the present invention, the bending die includes an upper mold base 50 and a lower mold body 60, and the upper mold base 50 and the lower mold body 60 are arranged correspondingly up and down On the CNC bending machine (not shown in the figure).

[0015] The cutter head 52 is fixedly connected to the upper mold base 50 by a plurality of screws 522 . The lower mold body 60 is provided with a groove 62 , and the groove 62 is arranged opposite to the cutter head 52 . The stripping block 64 is accommodated in the groove 62, and a spring 65 is arranged between the bottom surface 642 of the stripping block 64 and the lower mold body 60, and the stripping block 64 can be moved relative to the bottom surface 64 by the spring 65. The lower mold body 60 moves elastically. The bending block 66 includes a first side 662 and a second side 664 , the first side 662 is adjacent to the stripping bloc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap