Work device and emergency release system

一种应急下降、工作机的技术,应用在移土机/挖土机、上部结构、载荷吊挂元件等方向,能够解决驾驶室倾斜度改变、危及操作者等问题,达到简单结构、安全且可靠启动的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

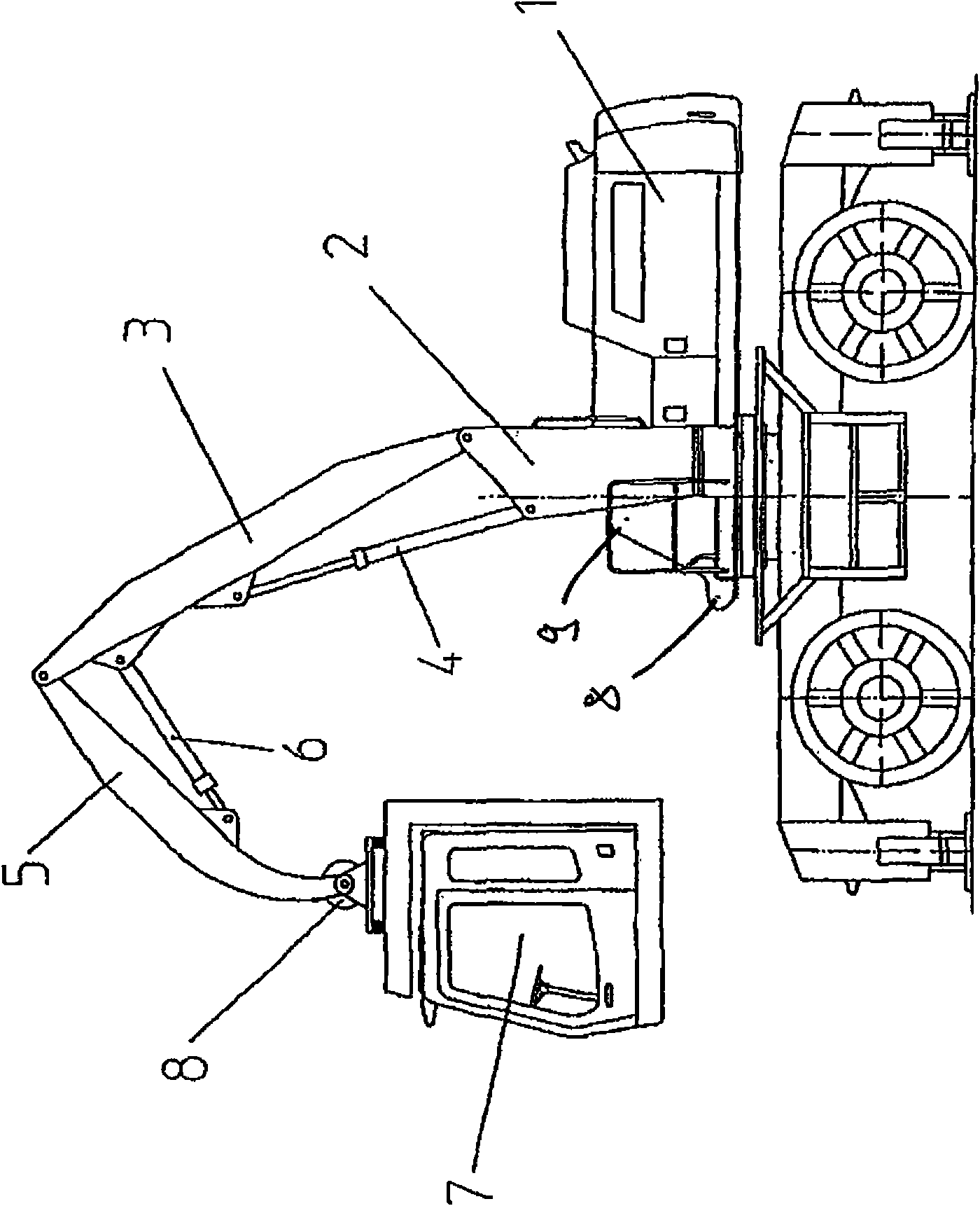

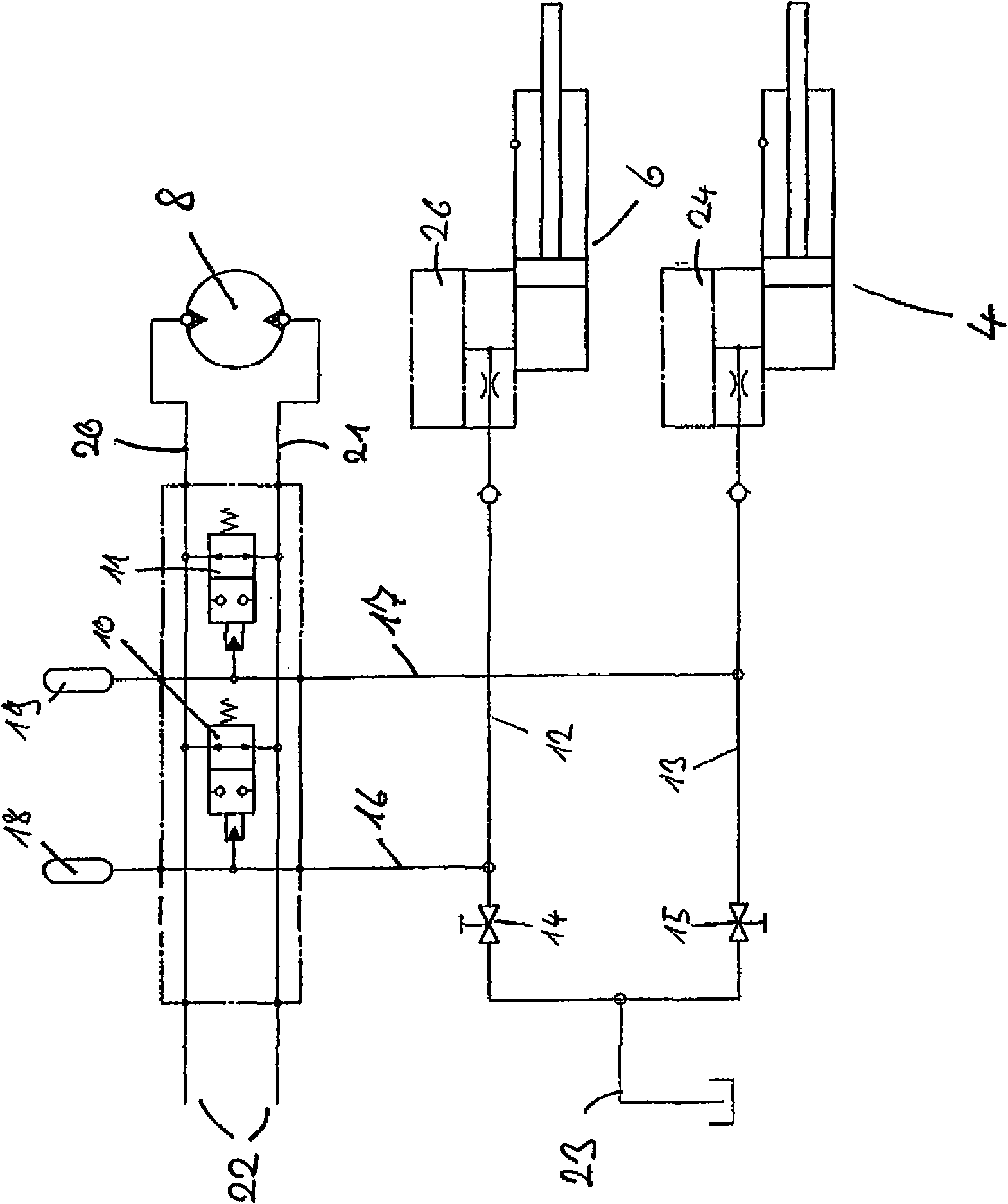

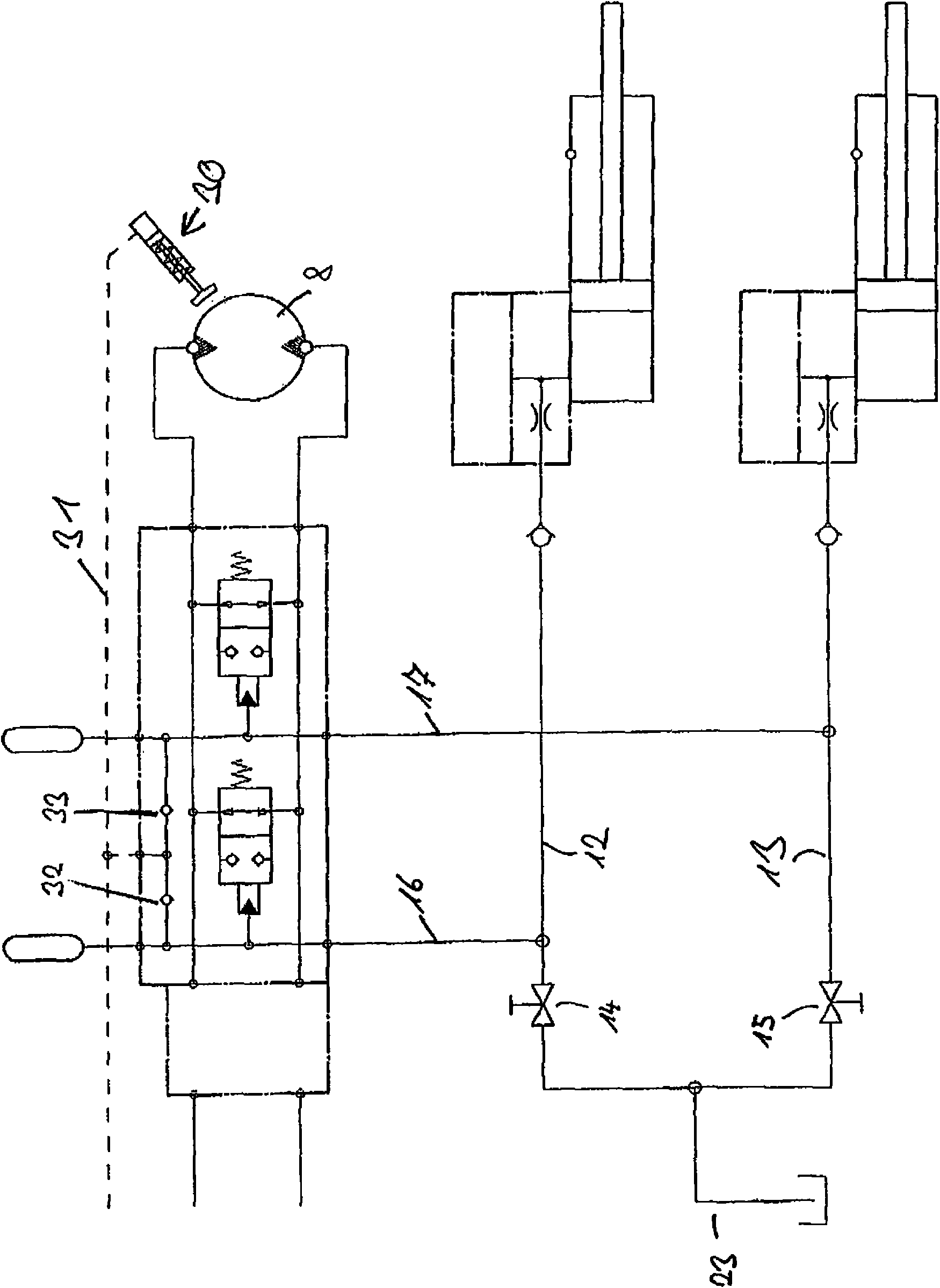

[0021] figure 1 An embodiment of a working machine according to the invention is shown. The working machine includes a movable bottom frame with an upper frame 1 mounted on the bottom frame in a manner capable of rotating around a vertical rotation axis, and the movable bottom frame and the upper frame 1 form a host. figure 1 A working boom, not shown in the figure, is usually pivotally mounted to the main machine. The working boom includes working tools such as buckets, grabs or hooks, and the working booms can be used for material handling, for example. in figure 1 In the embodiment shown in the figure, the working boom not shown in the figure can be pivotally mounted to the pivot points 8 and 9 of the upper frame 1. The working machine can be, for example, a material handler, crane or excavator for wood, waste or any other goods, especially hydraulic excavators.

[0022] The working machine includes a cab 7 from which the operator operates the working machine. The cab 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com