Equipment for tightening threaded fasteners

A technology of fasteners and equipment, applied in metal processing equipment, screwdrivers, wrenches, etc., can solve problems such as consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

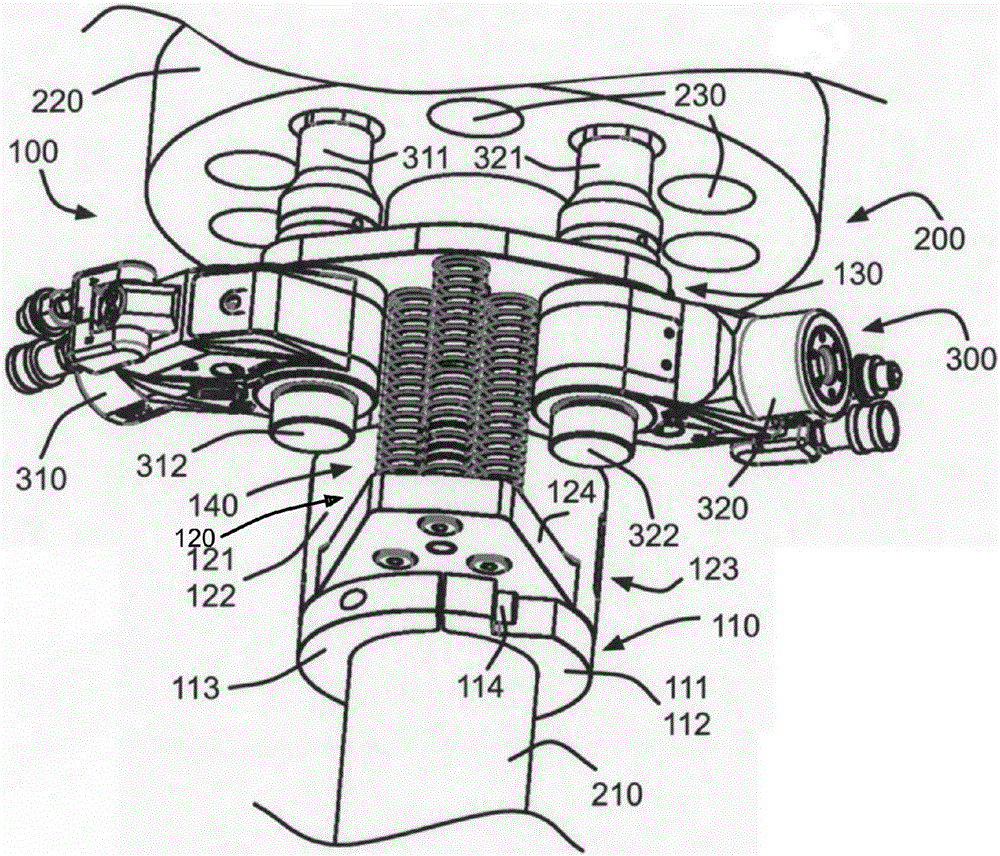

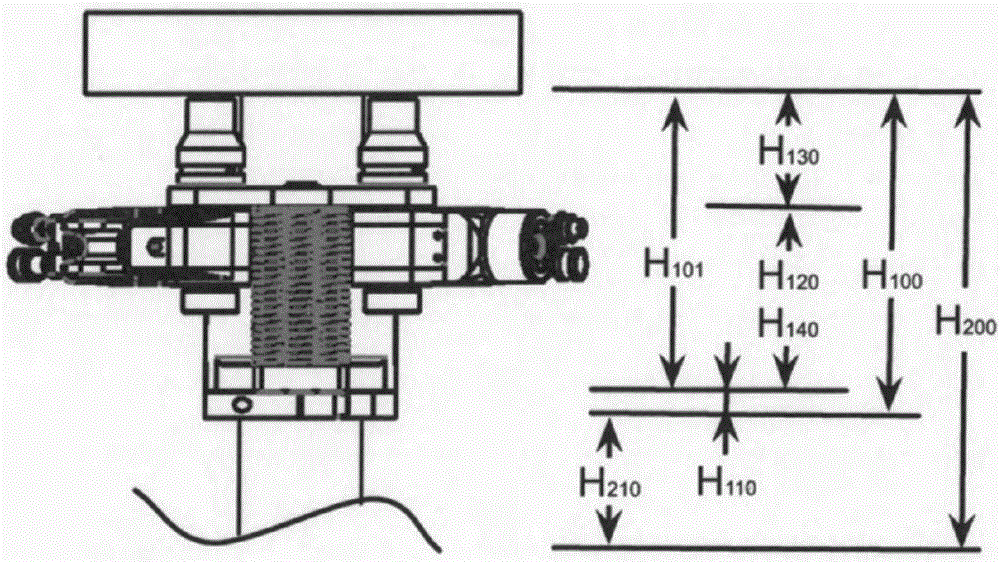

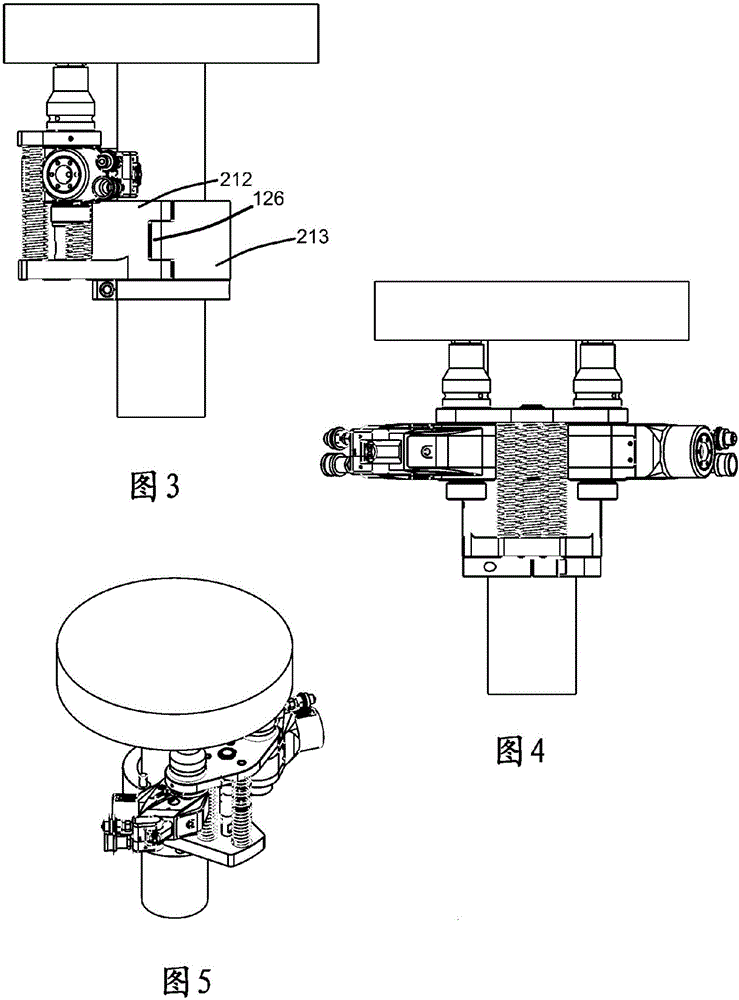

[0014] refer to figure 1 , illustrating the first aspect of the invention by way of example. An apparatus 100 is provided for counter-force and manual tightening and loosening of a threaded fastener 230 at location 200, reverse socket head screw (SHCS) at pressure seal head 202 of a main stop valve The connection locking part 201. The location 200 includes a tubular rod 210 , a flange 220 and a fastener or socket head screw 230 .

[0015] Apparatus 100 includes lower clamp assembly 110 , upper clamp assembly 120 , reaction adapter assembly 130 , and spring assembly 140 formed between upper clamp assembly 120 and reaction adapter assembly 130 . A lower clamping assembly 110 (eg, a stationary clamp) includes an annular hollow body 111 having a first portion 112 and a second portion 113 . The first part 112 and the second part 113 are connected on one side by a hinge (not shown) and on the other side by a locking mechanism 114 (eg a set screw). Lower clamp assembly 110 is non...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com