Method and device for detecting orientation characteristics on a web of material

A technology for detecting materials and material sheets, which is applied in the field of detecting directional features on material sheets, can solve the problems of material sheet warping, cost, and wrinkling, and achieve cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

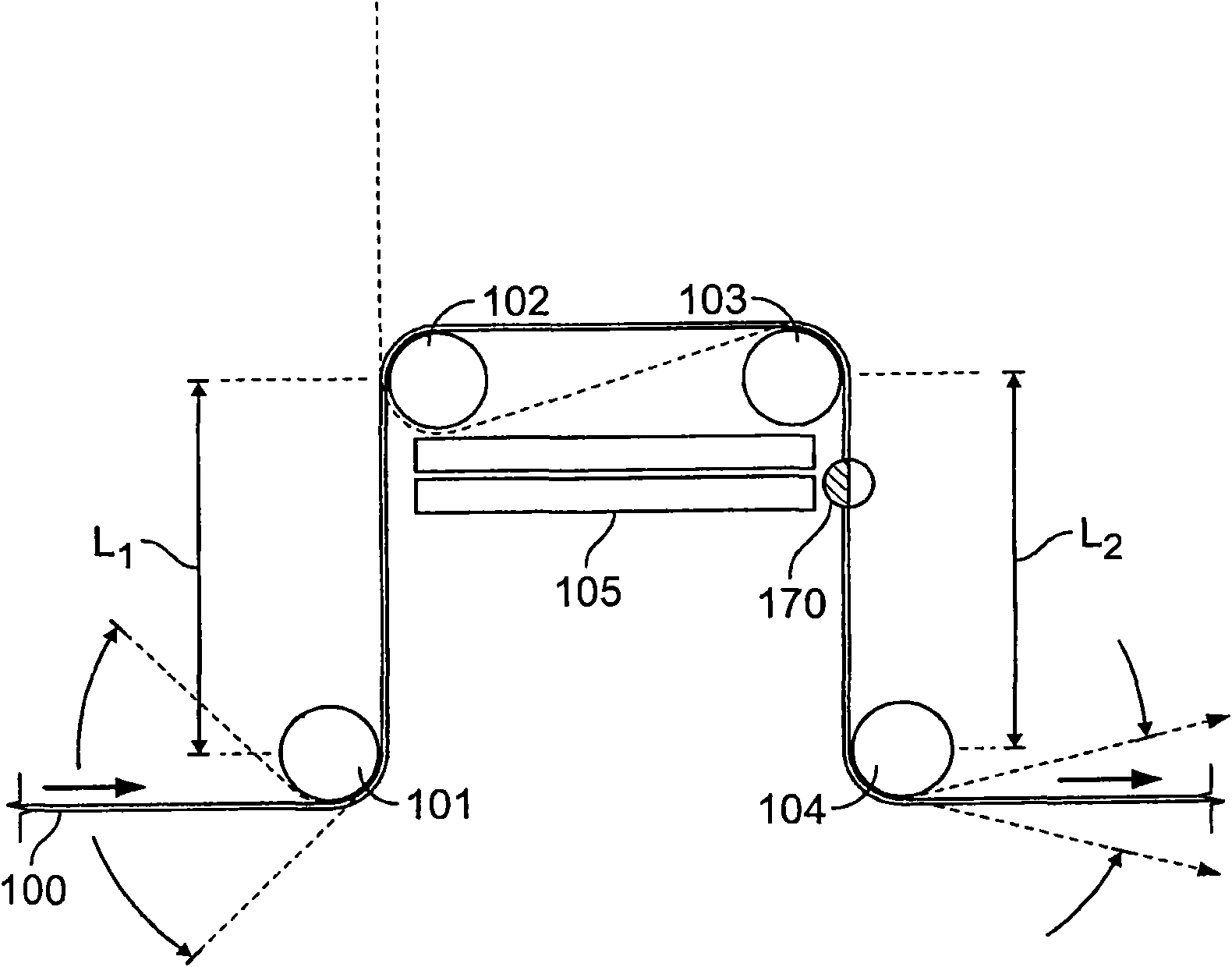

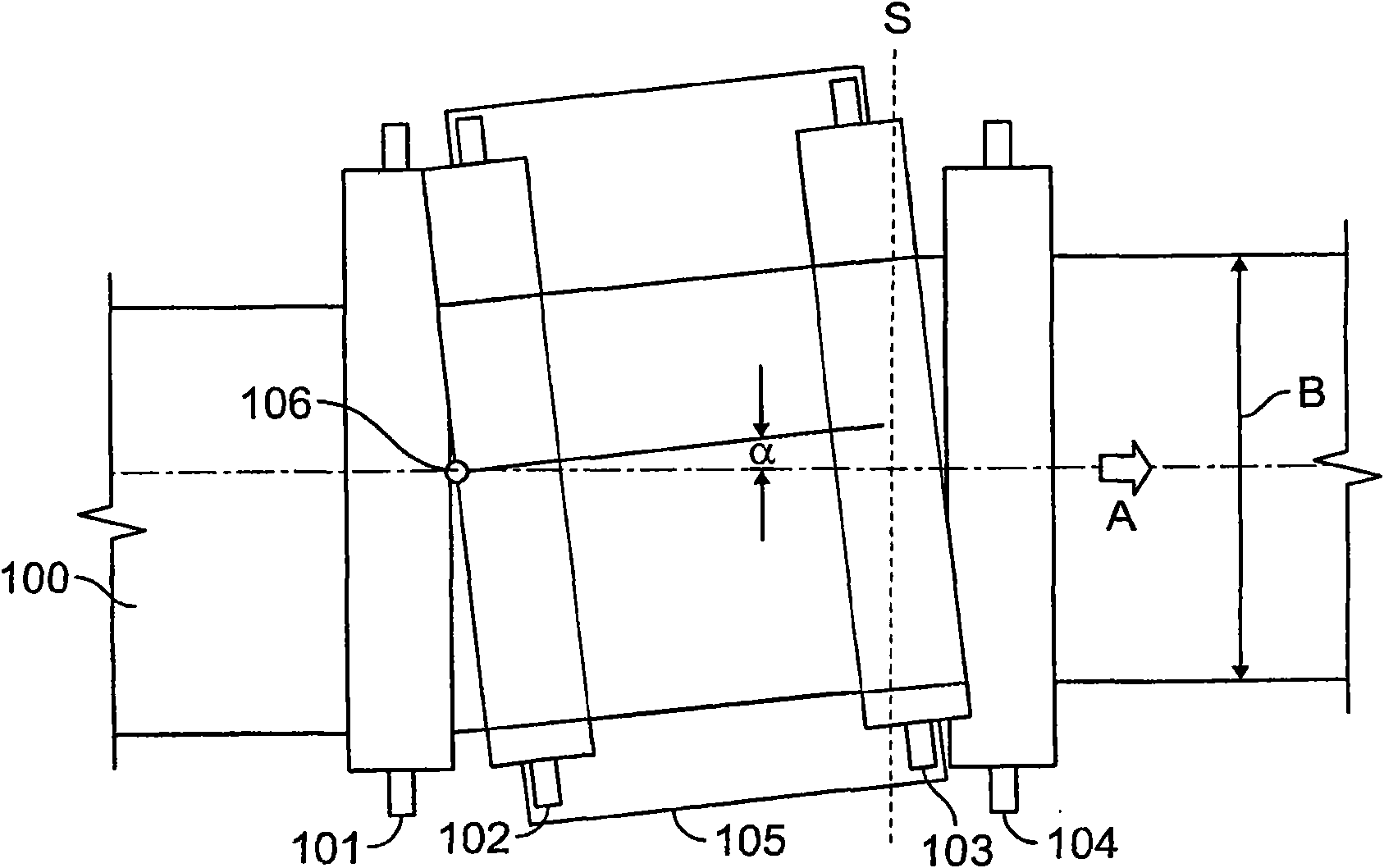

[0030] In devices that control the lateral deflection of sheets of material, such as Figure 1A and 1B As shown, at least one orientation feature may be used to determine lateral offset of the sheet of material relative to a predetermined position. The at least one orientation feature may for example be a line or a pattern on the sheet of material. This orientation feature may proceed in the direction of travel of the sheet of material and may be located near an edge of the sheet of material or may be the edge itself. The sensor element in this case may be a photosensor, such as a color sensor or a camera.

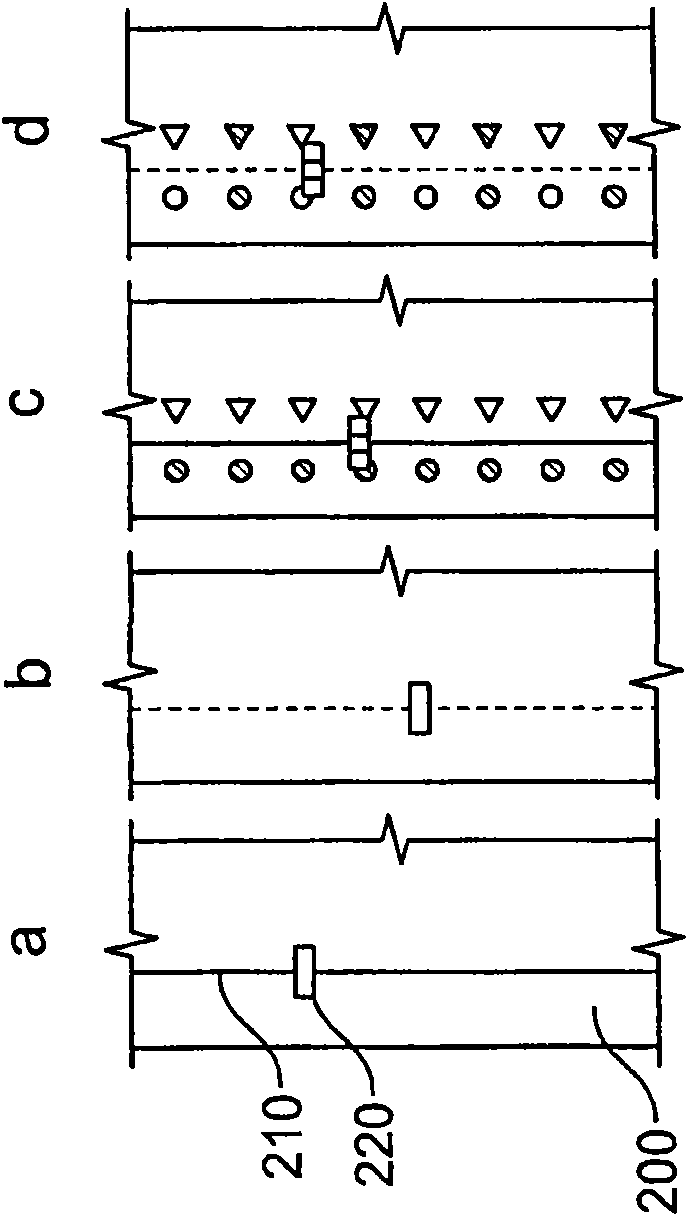

[0031] Figure 2A A sheet of material with lines as orientation features is illustrated. exist Figure 2A In a) of a), the line 210 on the sheet of material 200 is being sampled in the sensor area 220 . Figure 2A Solid lines are shown in a) and c) in stable and "cluttered" backgrounds, respectively. exist Figure 2A Dashed lines can be seen in b) and d) in stable a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com