Drawing bench of tobacco leaf

A technology for pulling rods and tobacco leaves, which is applied to harvesters, agricultural machinery and implements, applications, etc., to achieve the effect of improving labor productivity and facilitating neat stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

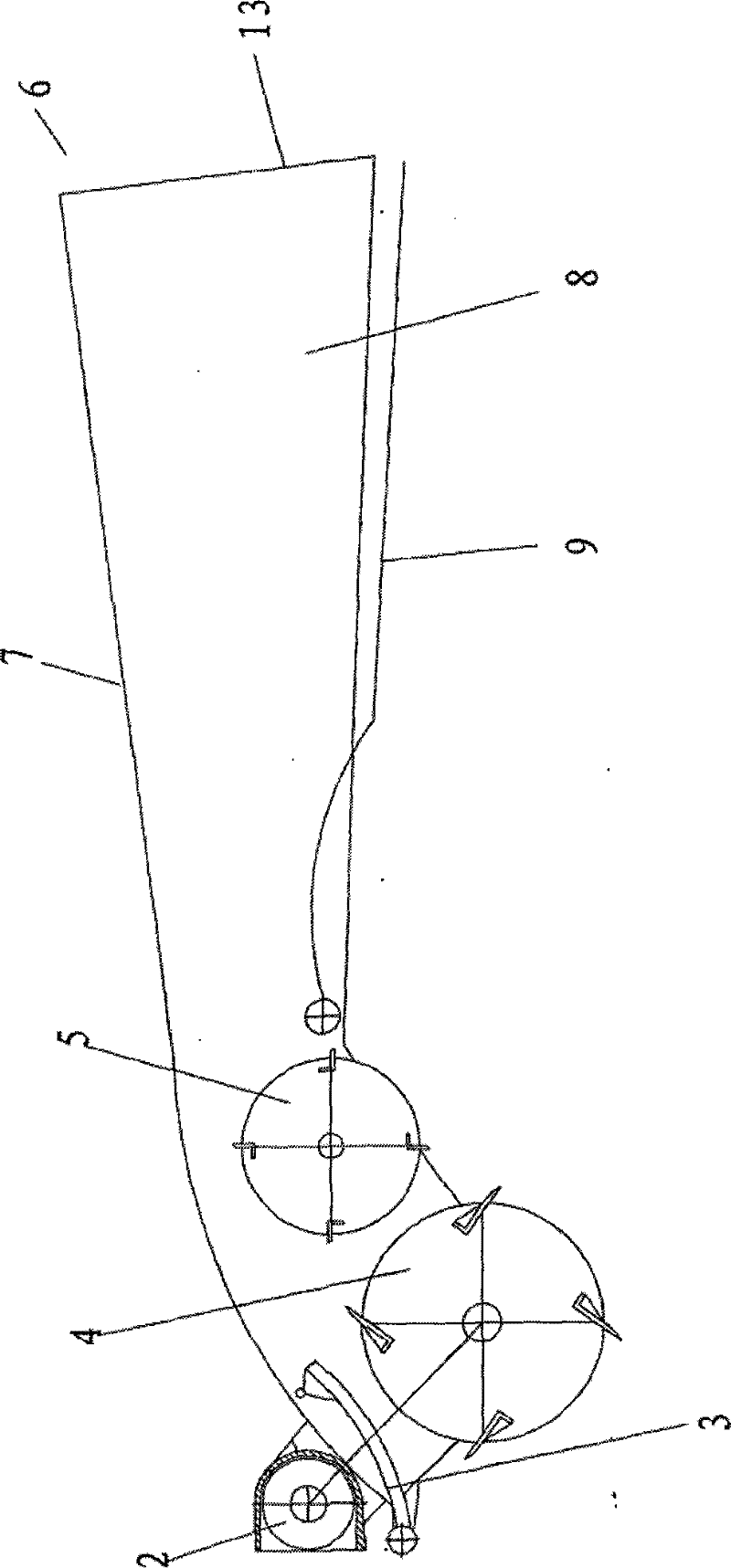

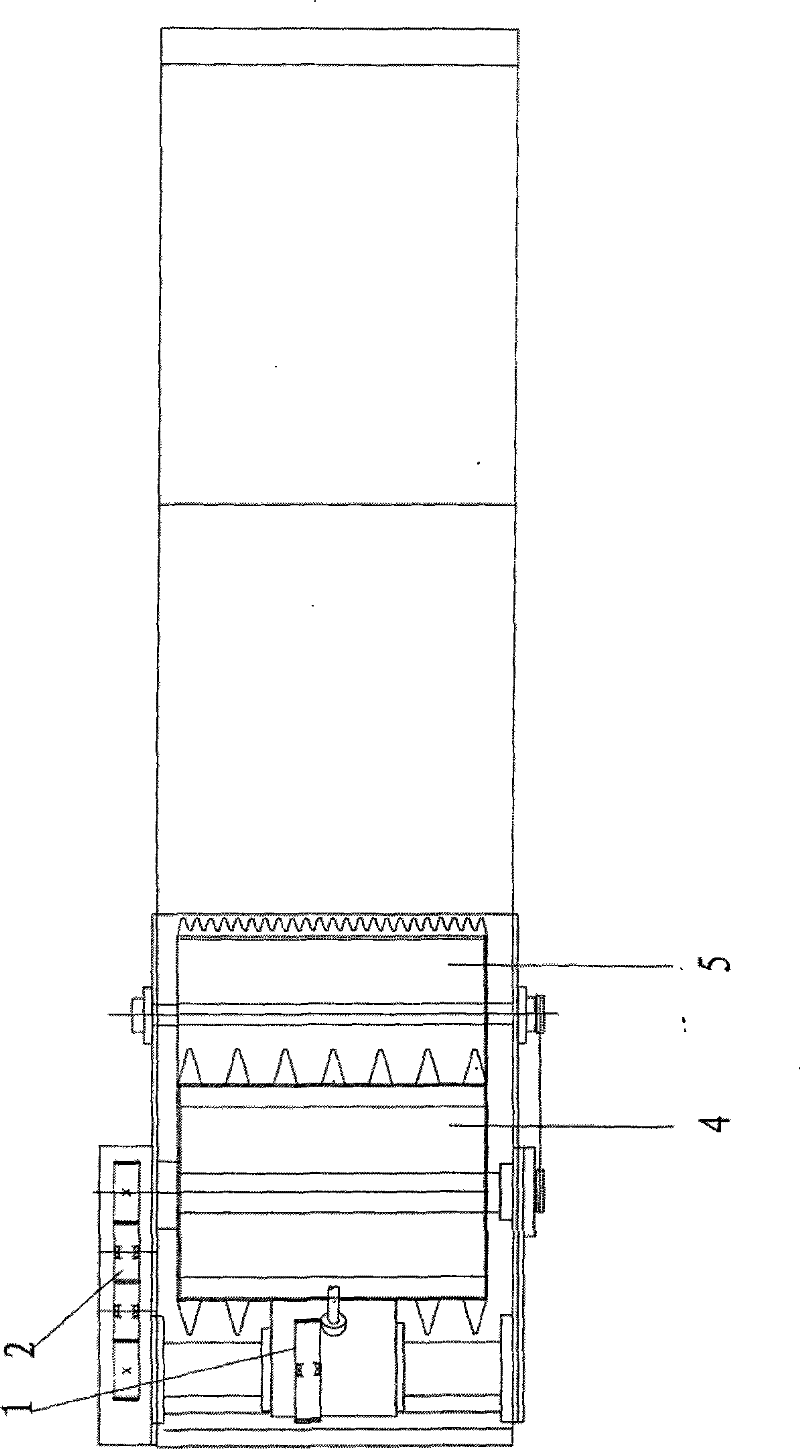

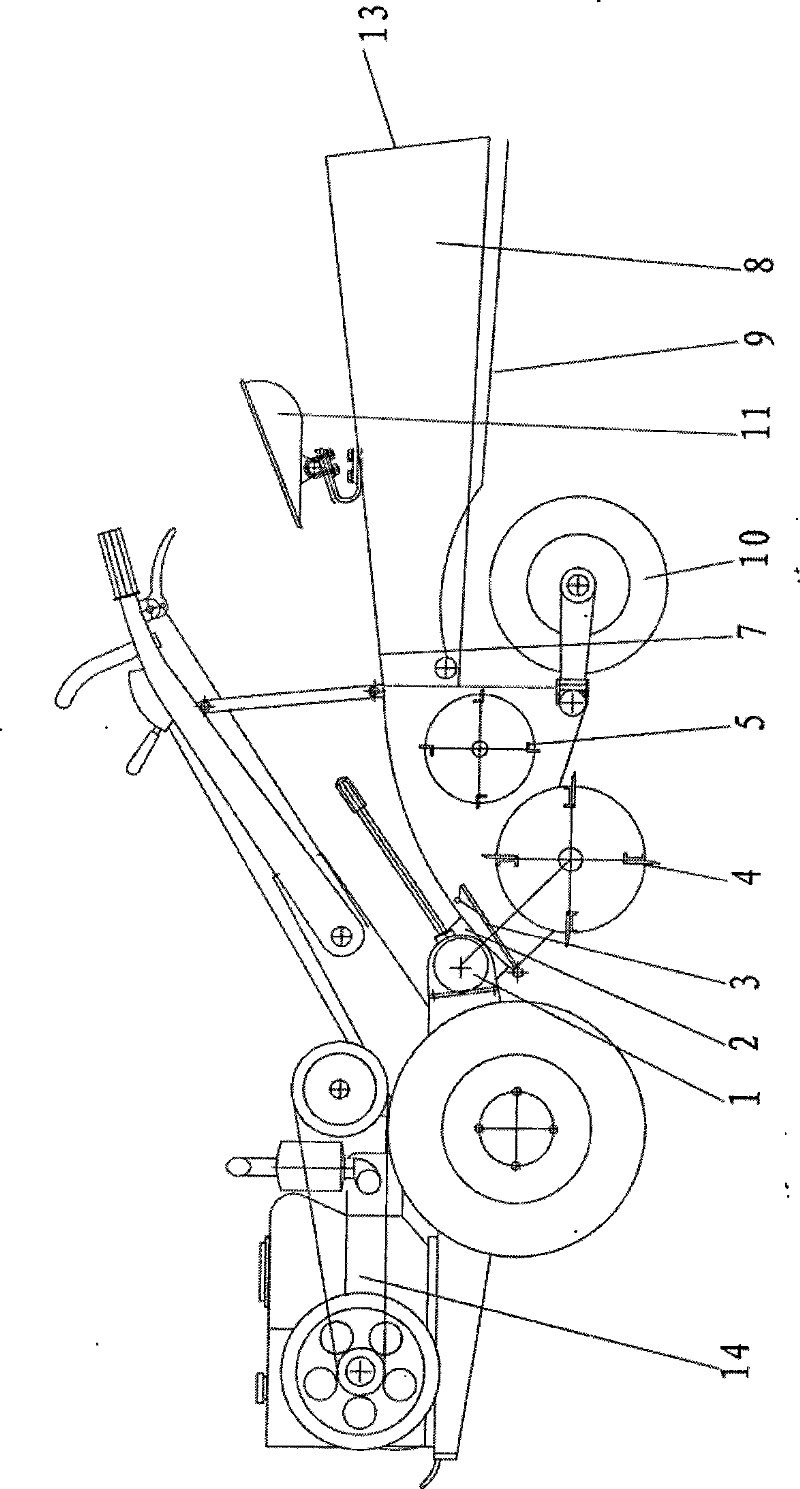

[0034] see figure 1 , figure 2 , Figure 7A and Figure 7B , a tobacco rod pulling machine, consisting of a gearbox 1, a transmission mechanism 2, a soil roller 3, a digging rotor 4, a rod delivery rotor 5 and a rod collection box 6, the transmission mechanism 2, the soil roller 3, the digging rotor 4 and the rod-feeding rotor 5 are installed below the machine cover plate 7, and the two sides of the machine cover plate 7 are provided with casing side plates 8. Composition, the rod feeding rotor 5 is located between the digging pocket rotor 4 and the rod collecting box 6, the digging pocket rotor 4 and the rod sending rotor 5 are arranged adjacently, and are axially parallel;

[0035] The power drives the transmission mechanism 2 through the gearbox 1, the transmission mechanism 2 drives the digging pocket rotor 4 to rotate, the digging pocket rotor 4 drives the rod feeding rotor 5 to rotate through the chain, the rod collecting box 6 is located behind the rod feeding roto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com