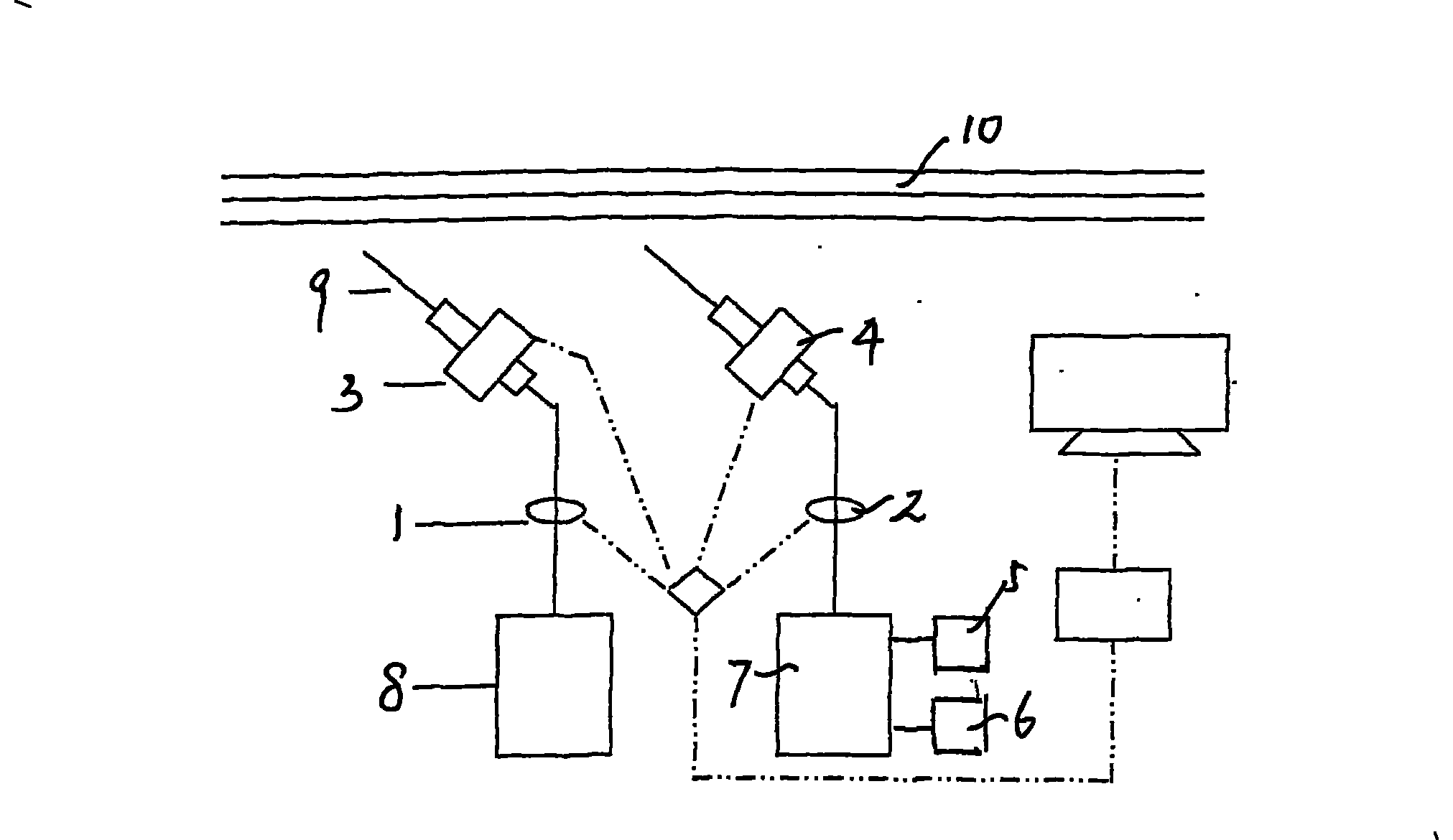

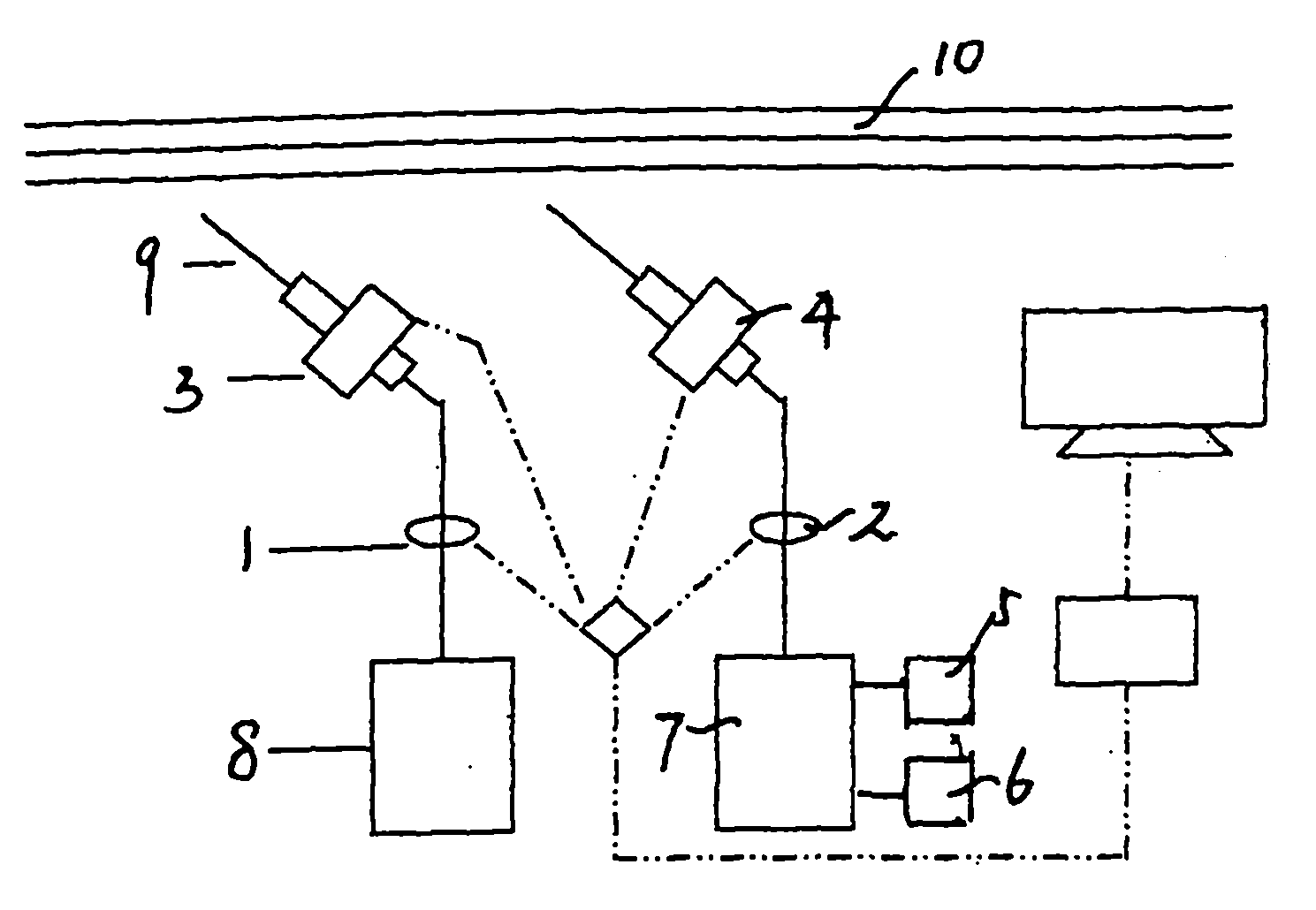

Dynamically-controlled filament breakage secondary automatic compensator

A technology of automatic compensation and dynamic management and control, which is applied in the program control, electrical program control, e-liquid filter and other directions in the sequence/logic controller to achieve the effect of good working effect, reasonable structure, stability and improvement of suction resistance stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0015] When the photoelectric sensor detects the breakage of the wire strand, the PLC of this device issues an instruction to start the first wire repair gun, and the first wire repair gun executes the automatic compensation function, and the automatic start is successful; the automatic detection device of the wire repair status detects the first wire repair The successful message of gun wire filling is fed back to the PLC and recorded, and the device runs until the end of the wire filling state; the device is ready for use.

example 2

[0017] When the photoelectric sensor detects the breakage of the wire strand, the PLC of this device issues an instruction to start the first wire replenishing gun, and the first wire replenishing gun performs the automatic compensation function, but the automatic start fails; Feedback to the PLC and record the unsuccessful threading gun message. The PLC issues an instruction to start the second wire feed gun and an alarm for the failure of the first wire feed gun; the second wire feed gun executes the automatic compensation function and automatically starts successfully; the automatic detection device for wire feed status detects that the second wire feed gun has compensated Silk success information, feedback to PLC and record. The device runs until the end of the wire feeding state; the first wire feeding gun is reset after maintenance, the PLC alarm is turned off, and the device is ready for use.

example 3

[0019] When the photoelectric sensor detects the breakage of the wire strand, the PLC of this device issues an instruction to start the first wire replenishing gun, and the first wire replenishing gun performs the automatic compensation function, but the automatic start fails; Feedback to the PLC and record the unsuccessful threading gun message. The PLC issues an instruction to start the second wire feeder gun and a fault alarm for the first wire feeder gun; the second wire feeder gun executes the automatic compensation function, but the automatic start also fails; the automatic detection device for wire feeder status detects that the second wire feeder Feedback to the PLC and record the unsuccessful threading of the thread gun. The PLC sends out a fault alarm for the second wire feeder gun; the control interface maintains the wire feeder fault state and gives an alarm until the two wire feeder guns are repaired and reset, the PLC alarm light turns off, and the device is read...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com