Triaxial vibration-decreasing/vibration-isolating platform of hammer crusher

A vibration-damping and vibration-isolating technology for coal crushers, which is applied to shock absorbers, gas-liquid shock absorbers, shock absorbers, etc. The problems such as multi-axial spatial vibration of ring hammer coal crusher can improve the dynamic environment, reduce the cost of production and maintenance, and reduce the cost of maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

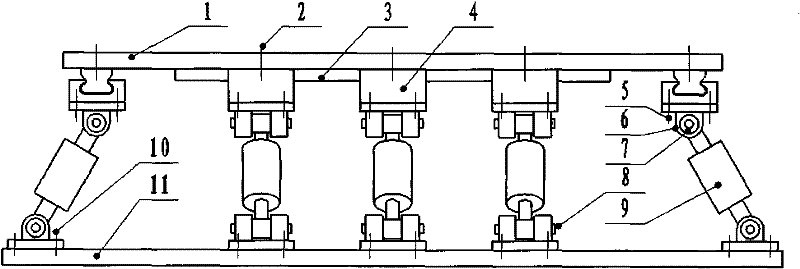

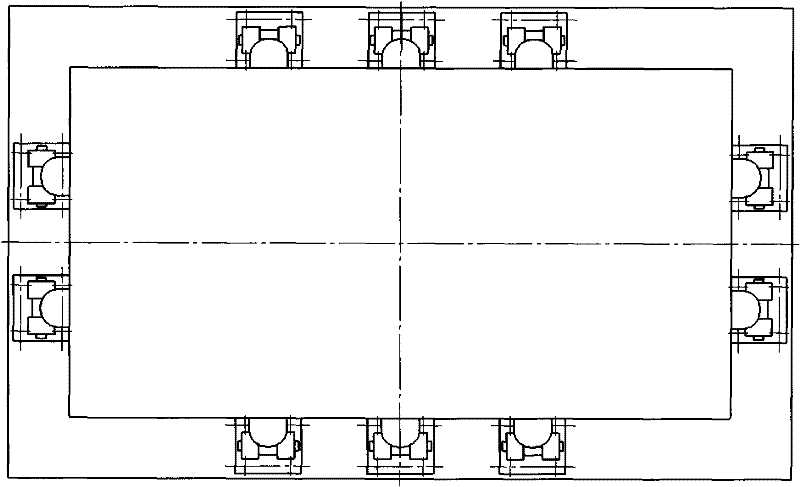

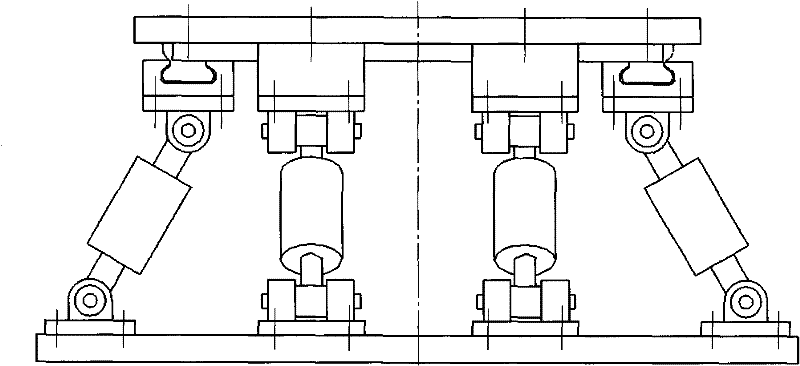

[0032] Specific implementation mode one: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 8As shown, the 3-RCRP space three-translation mechanism is composed of an upper platform 43, a lower platform 47 and three branch chains with the same structure, and each branch chain is composed of a rotating pair 45, a cylindrical pair 46, a rotating pair 45 and a moving pair 44 , wherein the axis of rotation of the rotating pair 45 is parallel to the guiding direction of the moving pair 44, the axes of rotation of the rotating pair 45 and the cylindrical pair 46 are perpendicular to each other, and the three branch chains are arranged symmetrically. The overall structure of the three-axis vibration-reducing vibration-isolation platform of the ring hammer coal crusher belongs to the space redundant three-translation mechanism formed by adding several branch chains to the 3-RCRP space three-translation mechanism. It consists of a moving platform 1, guide rail co...

specific Embodiment approach 2

[0033] Specific implementation mode two: as figure 1 , figure 2 , image 3 and Figure 6 As shown, the difference between this embodiment and Embodiment 1 is: the uniaxial vibration damping and vibration isolation device 9 consists of an oil-pneumatic spring lower connector (with pneumatic opening and closing quick joint) 21, a main cylinder body 22, a main air chamber 23, a main Piston 24, main piston seal 25, piston rod 26, main oil chamber 27, sliding bearing 28, master cylinder cover 29, cover screw 30, master cylinder seal 31, oil pipe joint 32, oil pipe 33, damping hole 34 , auxiliary cylinder upper cover plate 35, auxiliary oil chamber 36, auxiliary cylinder body 37, auxiliary piston seal 38, auxiliary piston 39, auxiliary air chamber 40, auxiliary cylinder lower cover plate (with pneumatic open and close quick joint) 41 , can realize double-acting uniaxial vibration damping and vibration isolation, through the oil-pneumatic spring lower connector (with pneumatic op...

specific Embodiment approach 3

[0034] Specific implementation mode three: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 7 As shown, the difference between this embodiment and Embodiment 1 is: the disc spring of the elastic element in the uniaxial vibration reduction and vibration isolation device 9 is replaced by a metal coil spring, and the damper 42 is directly connected with the moving platform 1 and the installation foundation 11 by using a ball joint. . The damper 42 is a fluid damper or a viscoelastic material damper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com