Positive and negative stiffness parallel three-translation vibration and impact isolation platform

A technology of positive and negative stiffness, isolation platform, applied in the direction of non-rotation vibration suppression, etc., can solve the problem of not being able to withstand shock loads, unable to achieve low-frequency vibration isolation, and the placement and number of damping elements are not conducive to damping adjustment and control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

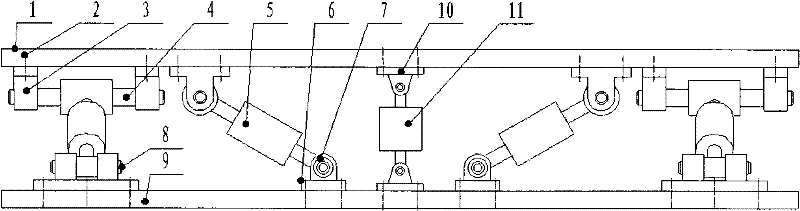

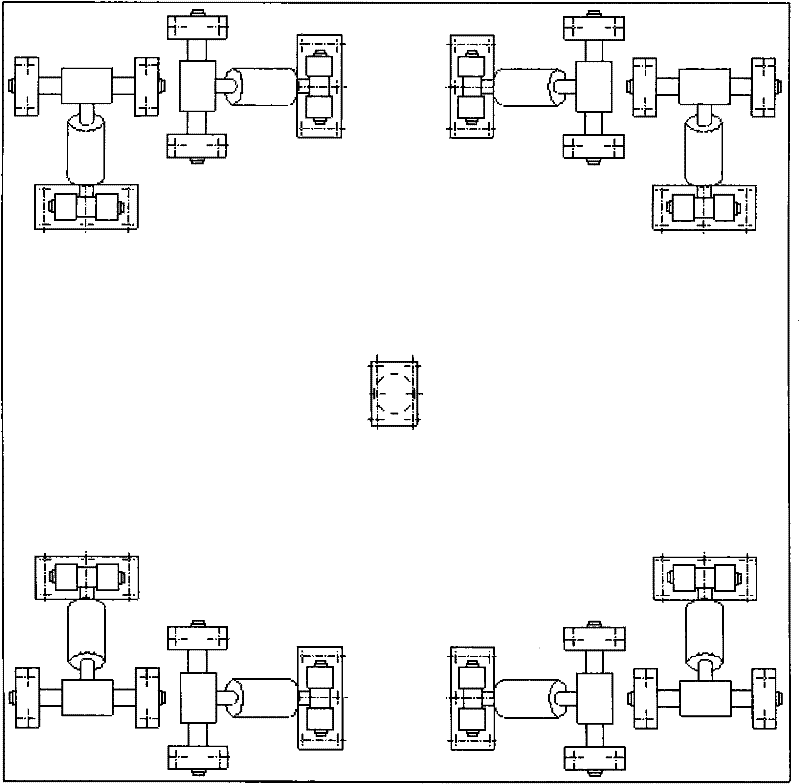

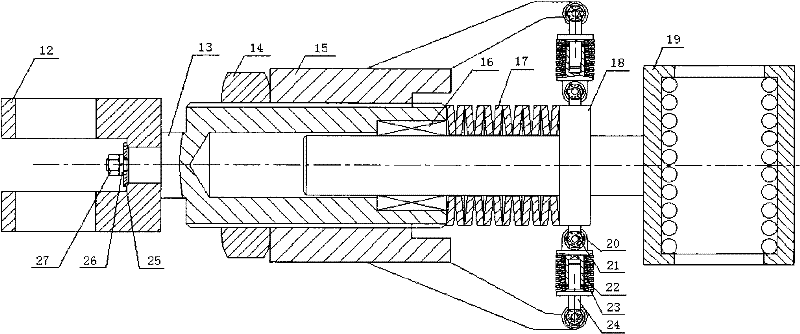

[0019]Embodiment 1: The three-translational vibration and shock isolation platform based on positive and negative stiffness parallel connection and controllable damping includes an upper platform 1, a lower platform 9, 8 elastic branch chain structures and a silicone magnetorheological damper 11; the elastic branch chain The structure includes an upper connecting bracket 3, a guide rod 4, a positive and negative stiffness parallel uniaxial vibration isolation device 5, a lower connecting bracket 6, a radial bearing 7, and a pin shaft 8. The positive and negative stiffness parallel uniaxial vibration isolation device 5 The upper connecting bracket 3 is connected by the guide rod 4, the lower connecting bracket 6 is connected by the pin shaft 8 and the radial bearing 7, the upper connecting bracket 3 is fixed on the upper platform 1 by the bracket connecting screw 2, and the lower connecting bracket 6 is fixed by the bracket connecting screw 2 On the lower platform 9; 8 elastic b...

Embodiment approach 2

[0020] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the radial bearing 7 and the guide rod linear bearing 19 adopt hydrostatic bearings to apply to large heavy-duty equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com