Automatic straightening machine for vehicle door assembly

A straightening machine and door technology, which is applied in the field of automatic straightening, can solve the problems of low pass rate of the door welding assembly, heavy workload of off-line inspection and repair of parts, and inability to completely solve the welding deformation of the car door, so as to achieve reliable quality and reduce labor intensity , to ensure the consistency of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

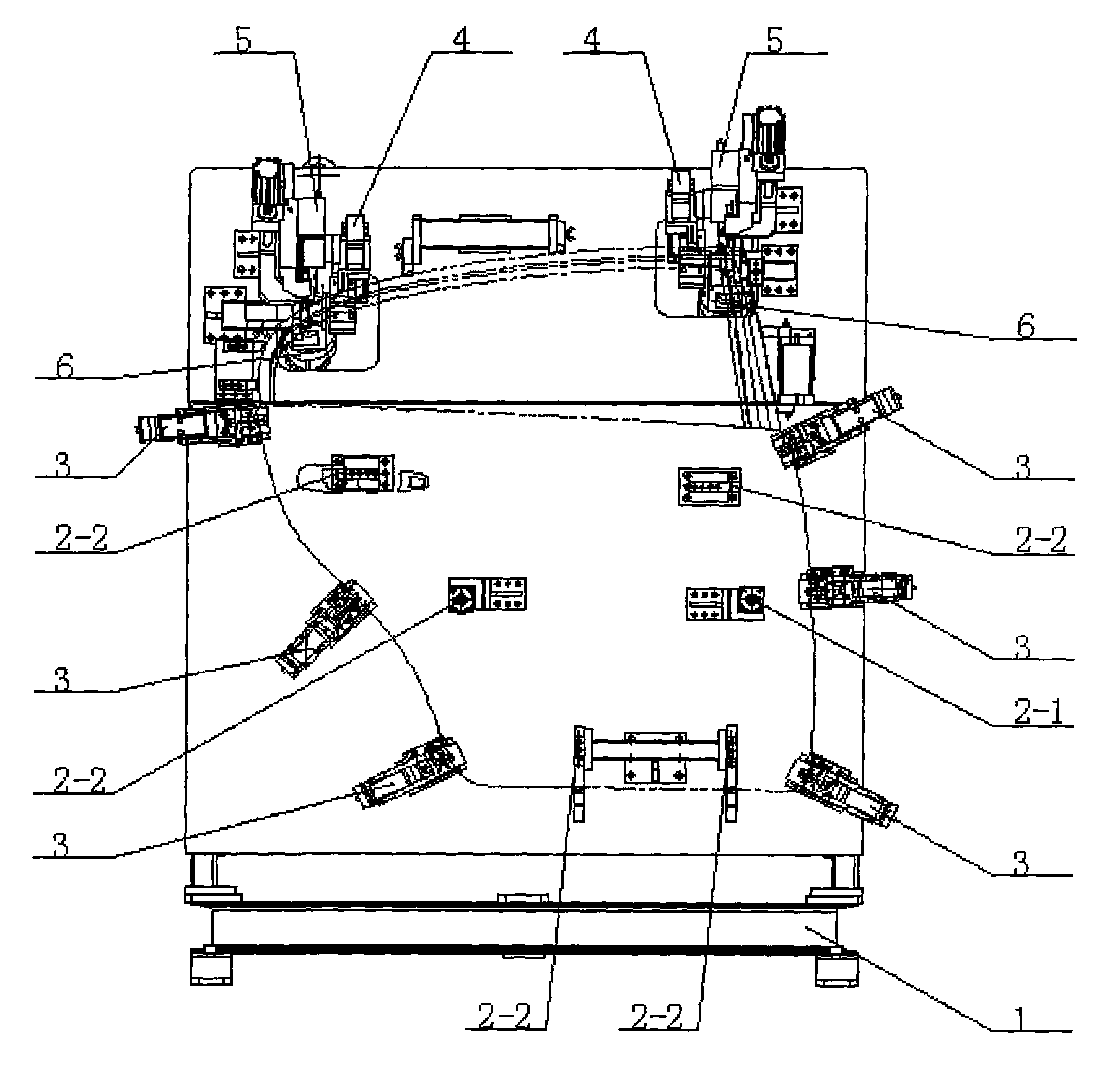

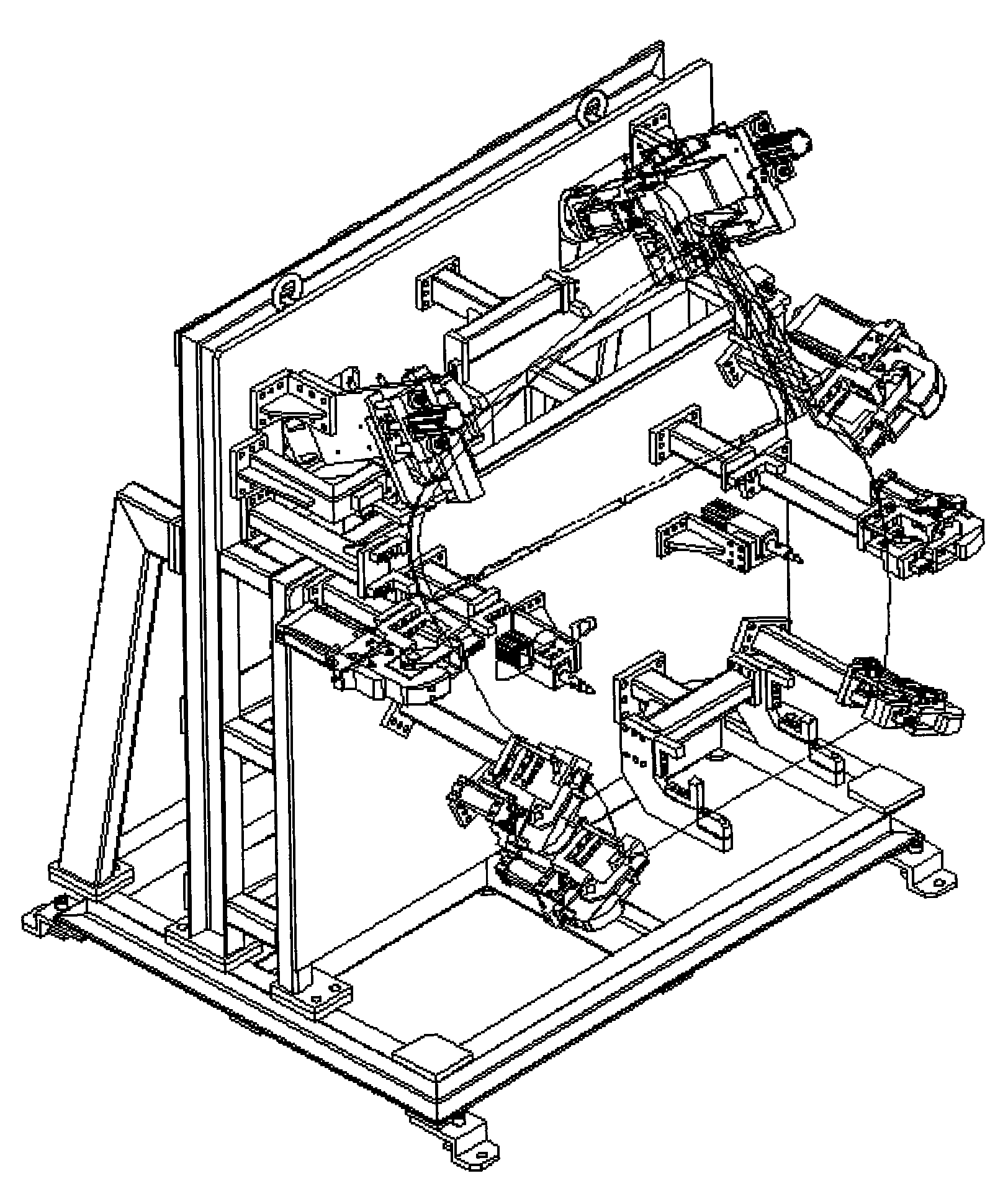

[0020] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 As shown, the automatic door assembly straightening machine is characterized in that it is composed of a mechanical system and an electrical system; wherein the mechanical system is composed of a straightening machine base 1, pneumatic components, a door positioning and clamping device, and a door window frame straightening device 4;

[0021] The pneumatic components are composed of the cylinder as the executive component, the air source processing component and the direction control component as the control component, and the air pipe and the joint as the connecting component. The source processing element and the direction control element are connected to the straightening machine base 1 through fasteners, and connected to the pneumatic actuator through the air pipe and the joint;

[0022] The door positioning clamping device is composed of 2 movable ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap