Oppositely clamped type direct-acting valve

A direct-acting valve and clamp-type technology, which is applied in the direction of lifting valve, valve detail, safety valve, etc., can solve the problems of increased manufacturing cost and bulkiness, and achieve the effects of reduced manufacturing cost, overall weight reduction and size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Next, an example as an embodiment of the present invention will be described based on the drawings.

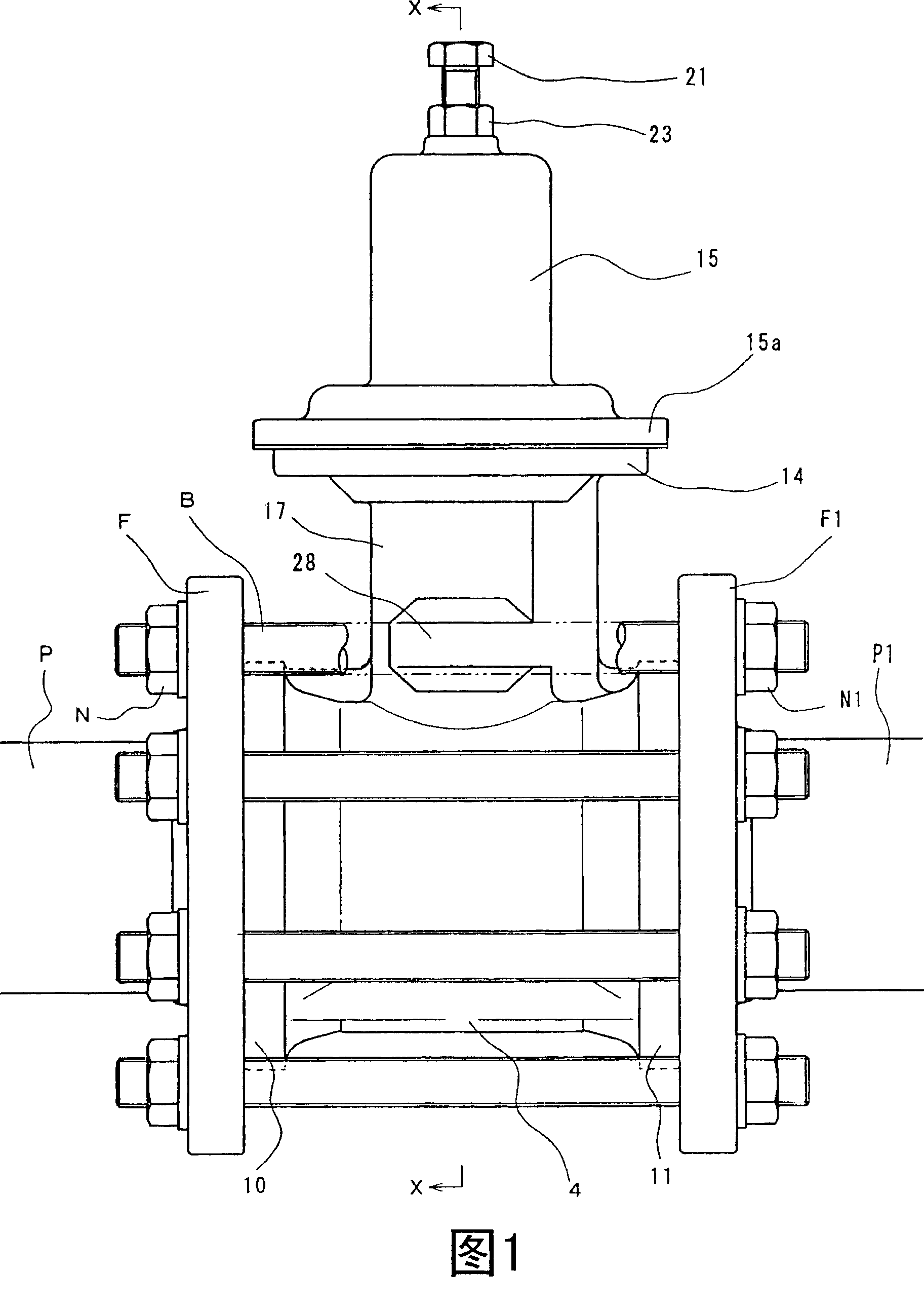

[0020] Fig. 1 is a front view of a piping state of a wafer type direct acting valve.

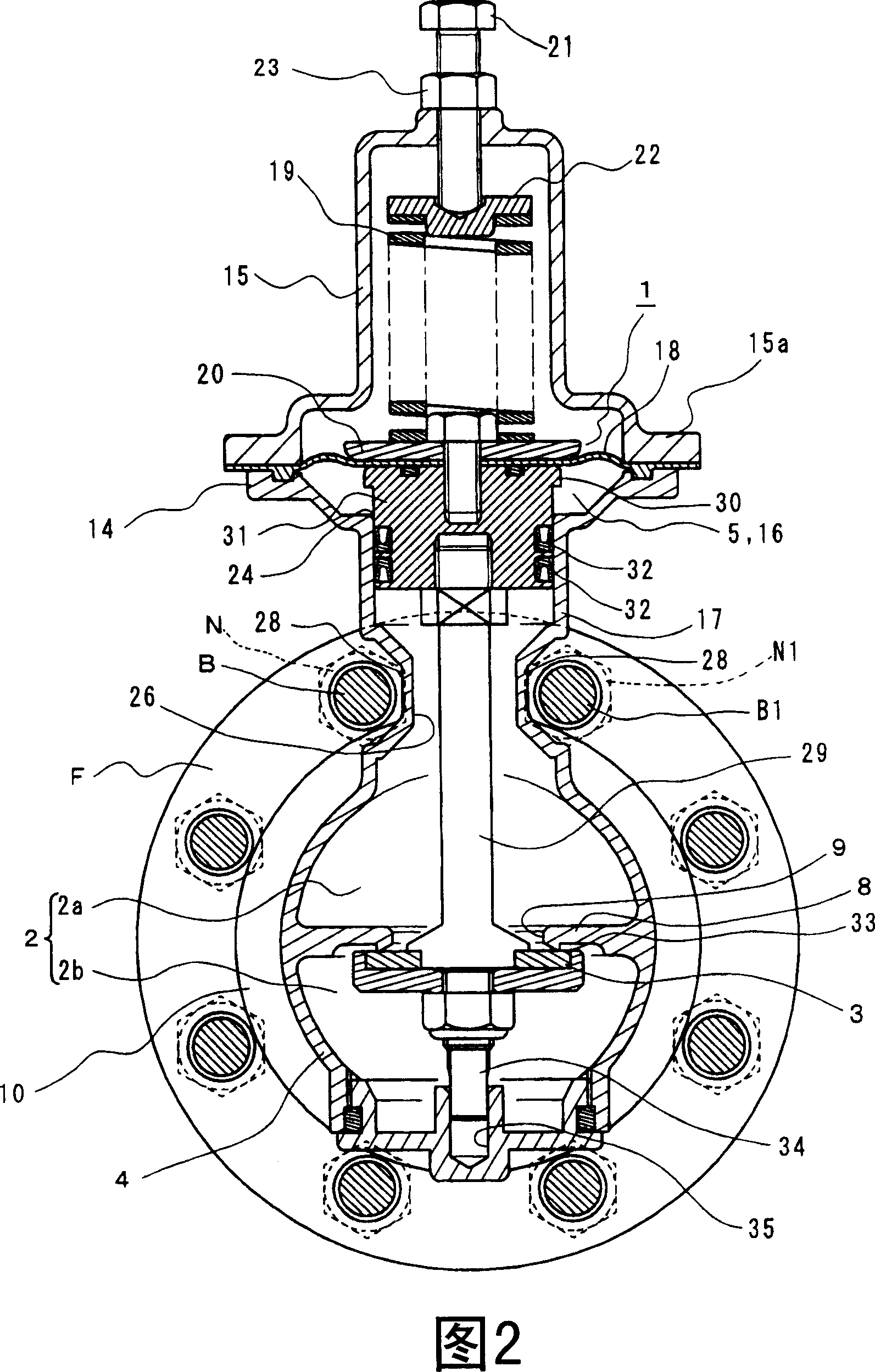

[0021] Fig. 2 is a cross-sectional view taken along line X-X of Fig. 1 .

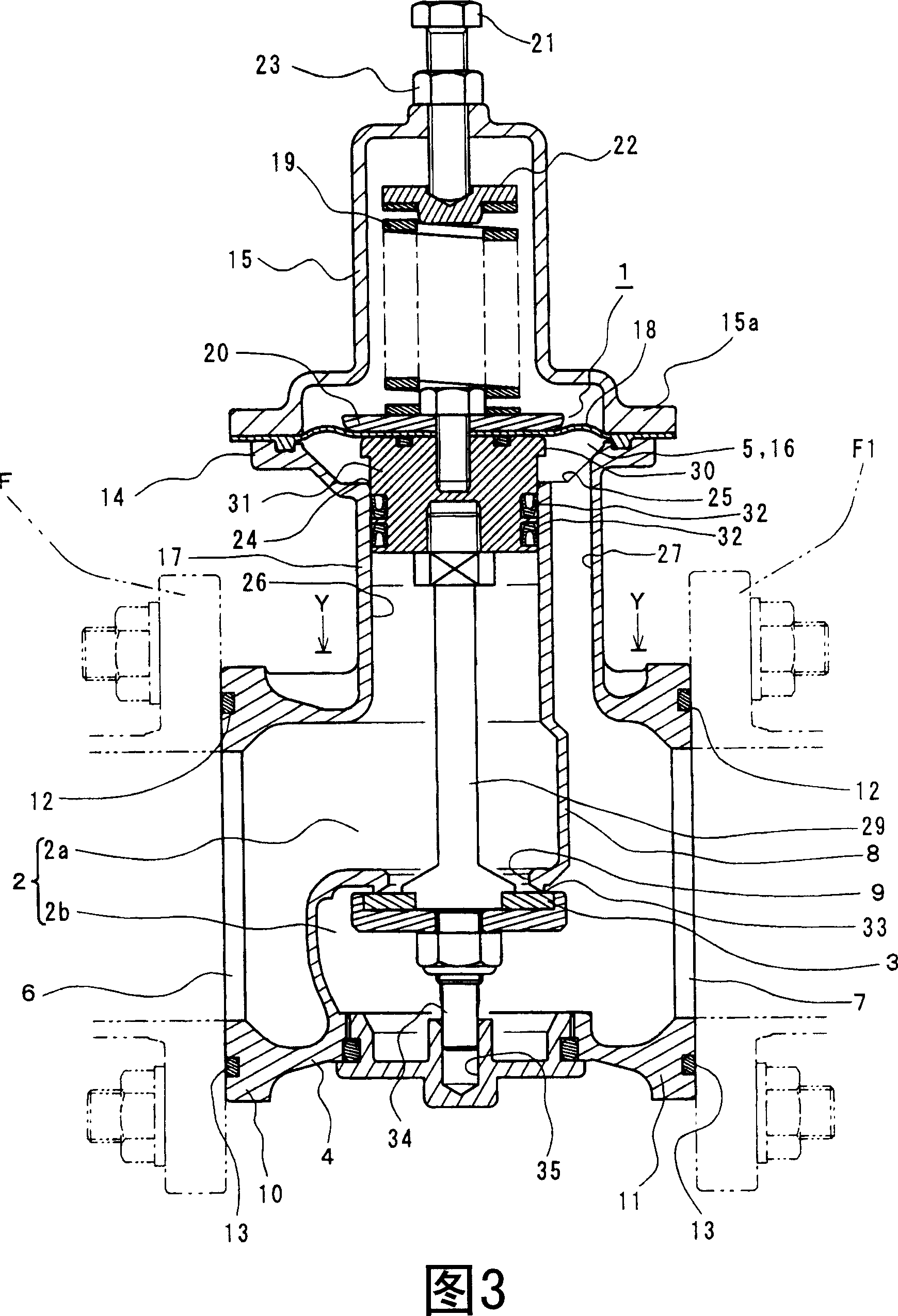

[0022] Fig. 3 is a longitudinal sectional view taken along line X-X in Fig. 1 .

[0023] FIG. 4 is an enlarged cross-sectional view taken along line Y-Y of FIG. 3 with part omitted.

[0024] The valve is a direct-acting valve, which includes a driving part 1 that operates when primary pressure or secondary pressure is detected, and a valve body 3 that communicates with (or is connected to) the driving part 1 and is manipulated to open and close flow path 2. The valve shown is a direct acting pressure reducing valve.

[0025] The structure of the direct acting pressure reducing valve is as follows. The valve box (or valve chamber) 4 includes the flow path 2 (including the primary flow path 2a and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com