Automatic processing device of flattened waste bottles and cans and device thereof

An automatic processing and bottle-can technology, applied in the field of presses, can solve the problems of low utilization space of waste bins, low waste transportation efficiency, and large space of waste bins, so as to improve environmental protection awareness, promote social environmental protection, and improve the use of space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Further details will be given below in conjunction with the preferred embodiments shown in the accompanying drawings.

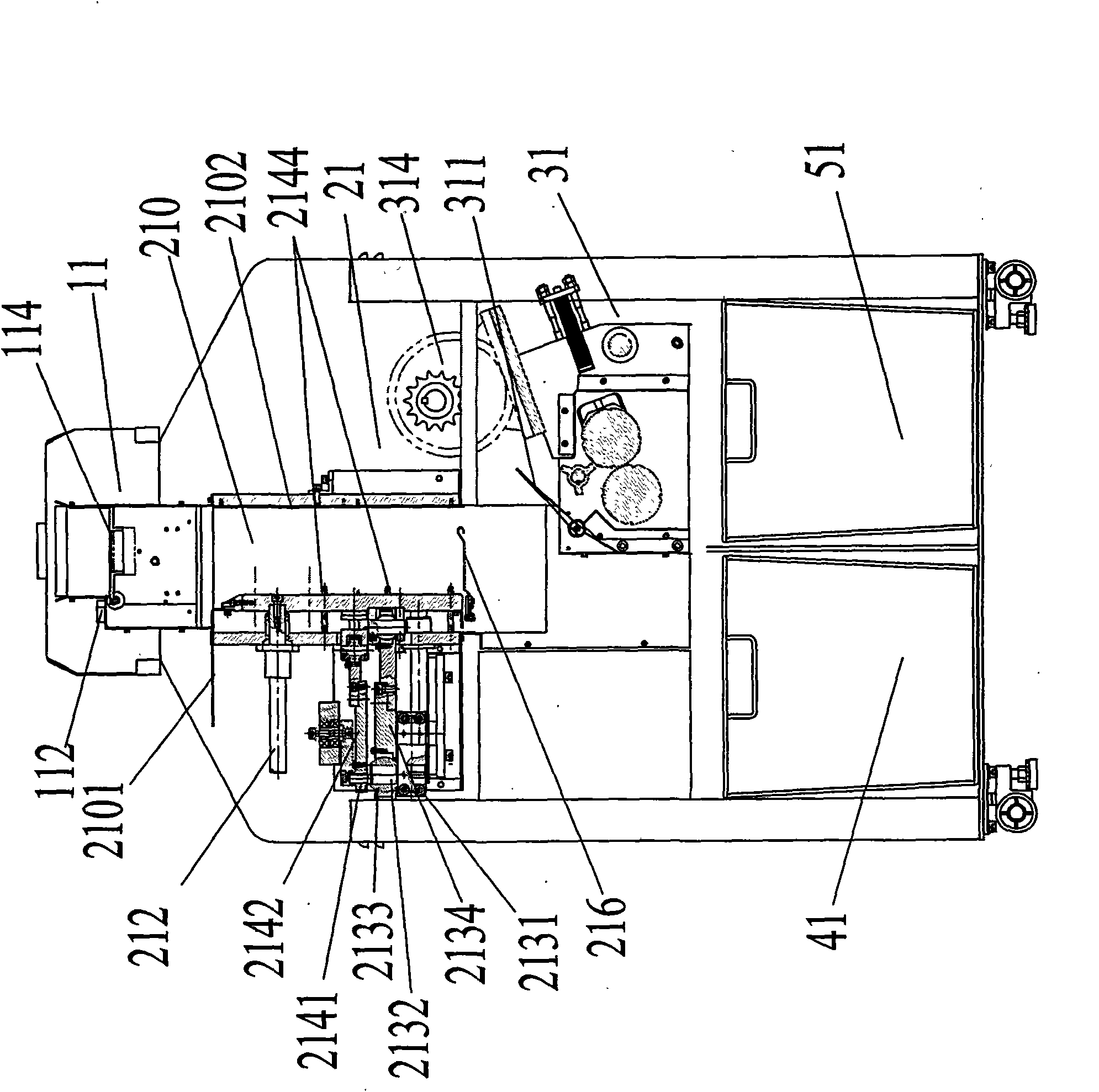

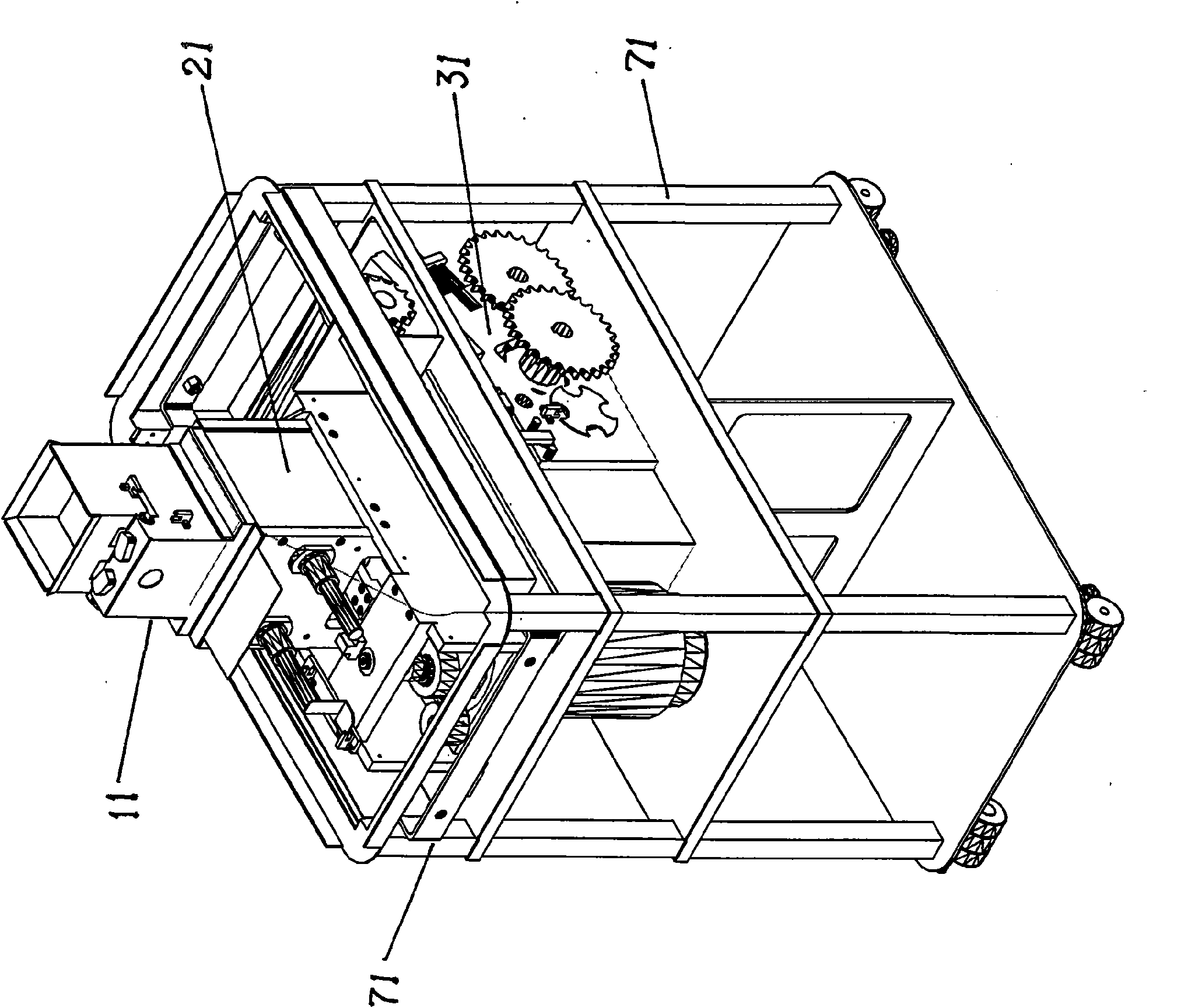

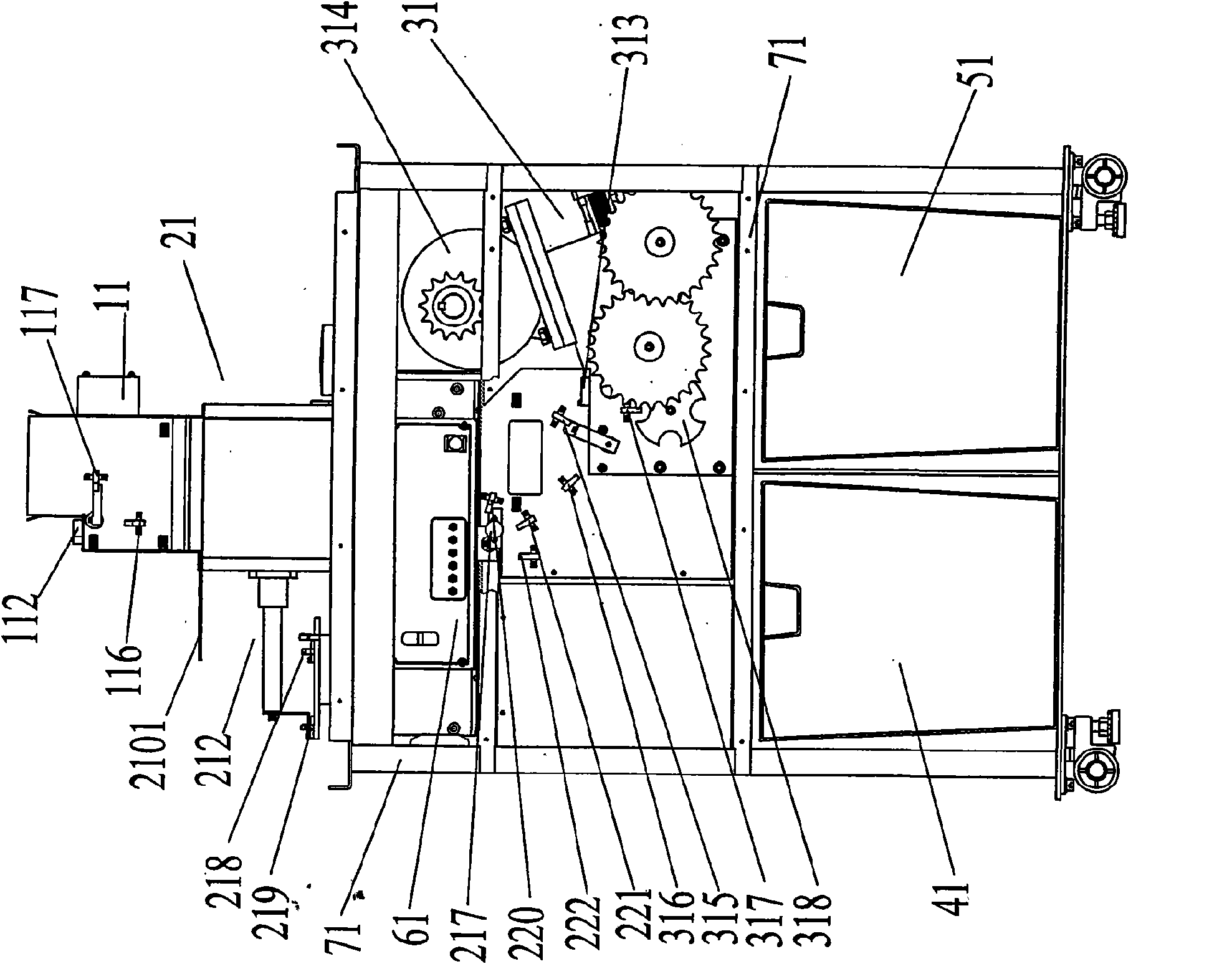

[0018] Such as Figure 1 to Figure 3 As shown, the automatic processing device for crushing waste bottles and cans includes a feeding mechanism 11, a crushing mechanism 21, a rolling mechanism 31, a first material barrel 41, a second material barrel 51, a microprocessor 61 and a frame 71; The material mechanism 11 is fixed on the flattening mechanism 21, and the outlet of the lower end of the feeding mechanism 11 is facing the entrance of the flattening mechanism 21; the flattening mechanism 21 is fixed on the frame 71; the rolling mechanism 31 is also fixed on the frame 71, Place below the flattening mechanism 21; the lower end outlet of the flattening mechanism 21 is facing the entrance of the rolling mechanism 31; the first material bucket 41 and the second material bucket 51 are arranged side by side on the lowest part of the frame 71, and the flat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com