TN first minimum nematic liquid crystal mixture and method for preparing same

A mixed liquid crystal, extremely small technology, applied in the direction of liquid crystal materials, chemical instruments and methods, etc., to achieve the effects of good response time, improved clearing point, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

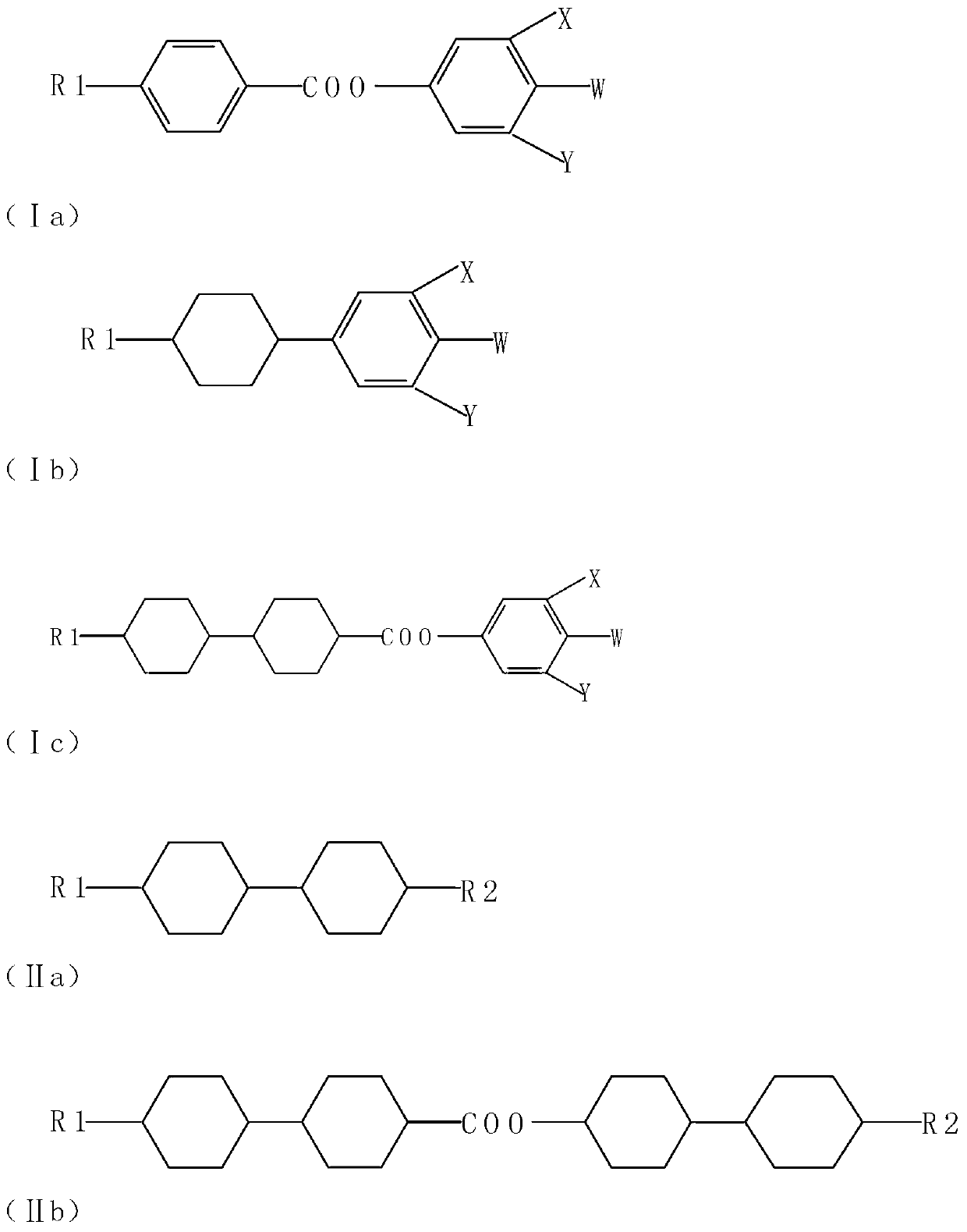

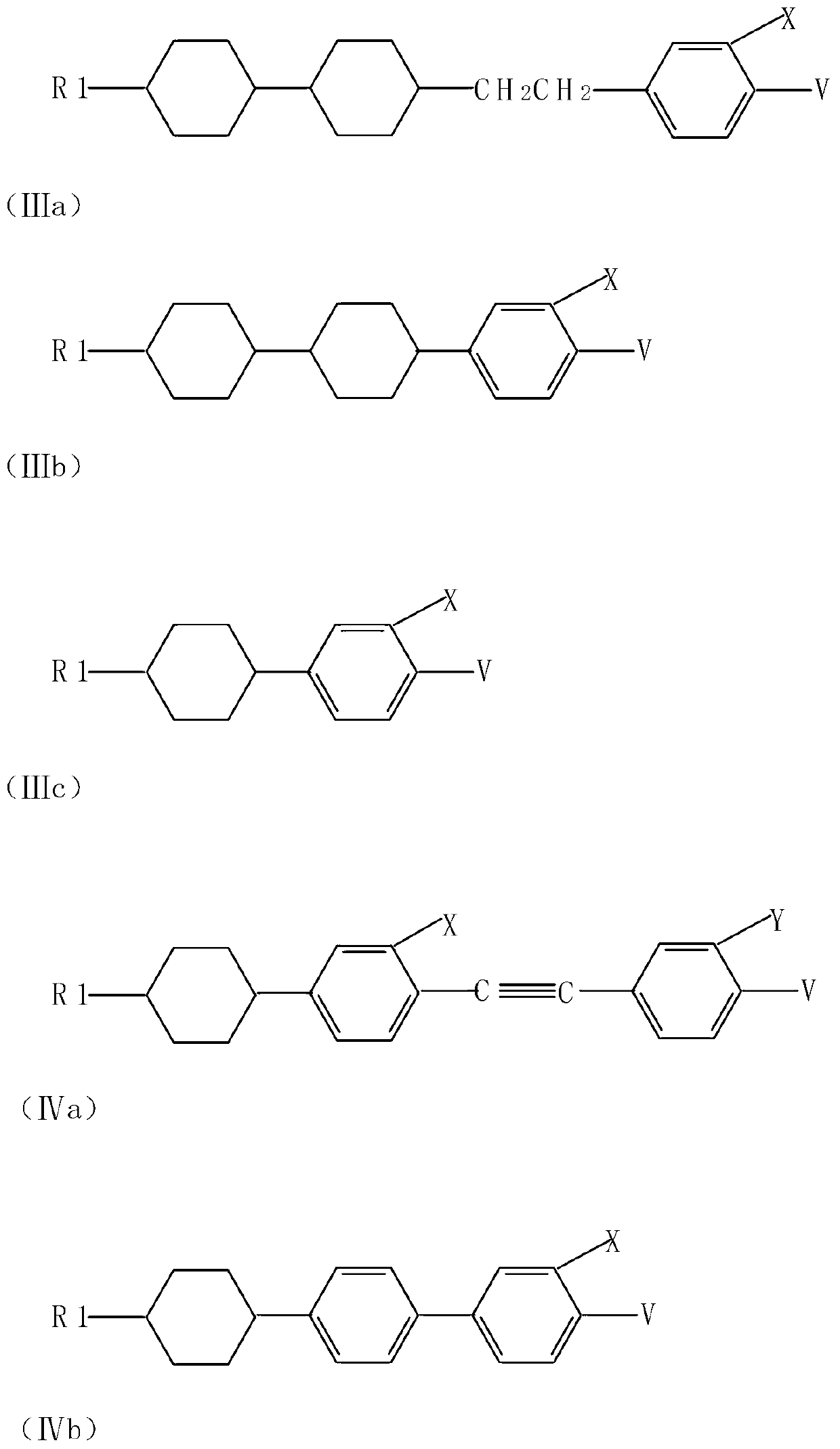

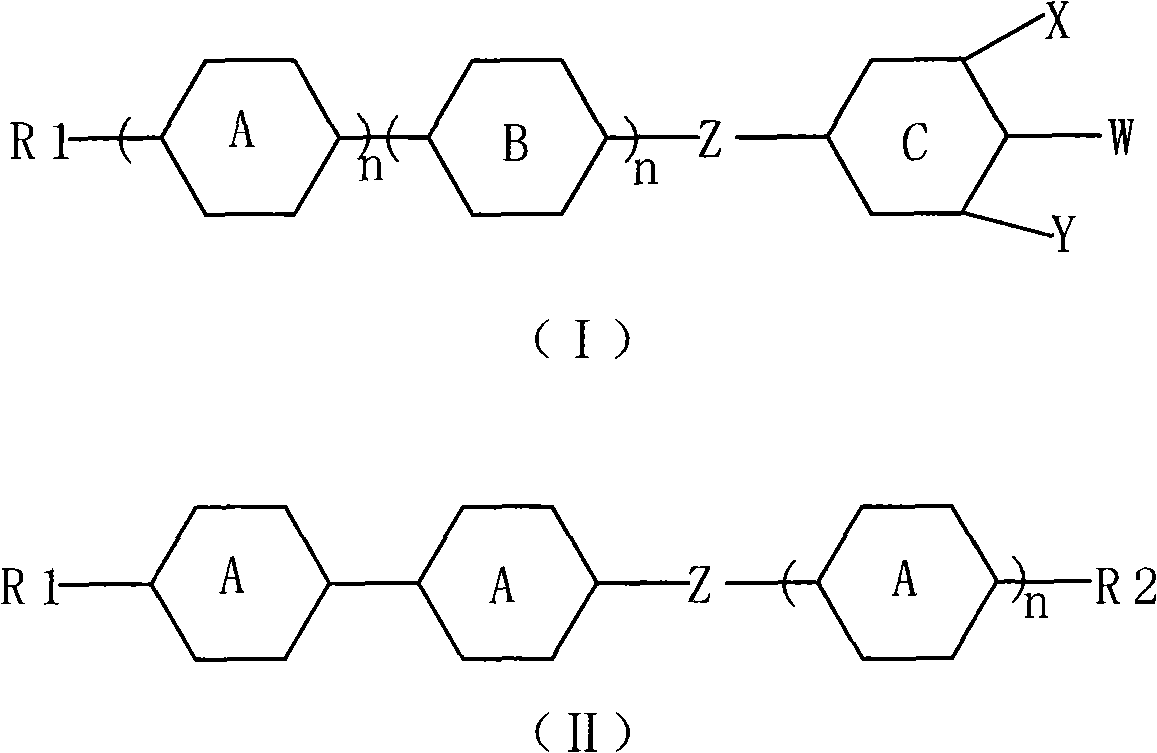

Method used

Image

Examples

Embodiment 1

[0057] Compound Percentage / %

[0058] 3CCP2F 10

[0059] 4CCP2F 10

[0060] 5CCP2F 12

[0061] 3CCePF 8

[0062] 5CCePF 12

[0063] 3CCPET2 3

[0064] 3CC-CC3 2

[0065] 3CC-P3F 6

[0066] 5CC-P3F 5

[0067] 3CC5 4

[0068] 3CC4 4

[0069] 3CPF 2

[0070] 2P-PN2F 2

[0071] 3P-PN2F 5

[0072] 1-4bP-PN2F 5

[0073] 5CPN2F 10

[0074] The proportion of various liquid crystal compounds in the bottle of TN first minimal mixed liquid crystal formula is: 33% of type I liquid crystal compound, 10% of type II liquid crystal compound, 57% of type III liquid crystal compound, and 0% of type IV liquid crystal compound. Weigh each liquid crystal compound according to the proportion of the formula, heat and stir to dissolve into a fluid state after weighing, vacuumize nitrogen replacement to maintain a vacuum of 50KPa, heat to a clear point, naturally cool to room temperature while stirring, and filter. Filtered TN first minimal nematic phase mixed liquid crystal, then add t...

Embodiment 2

[0079] Compound Percentage / %

[0080] 5CCP2F 8

[0081] 3CCPr 5

[0082] 3CCP2F 4

[0083] 3CCePr 8

[0084] 3CC4 4

[0085] 3CC5 4

[0086] 5CCv 3

[0087] 3CCePF 5

[0088] 5CCePF 10

[0089] 3CCPET2 3

[0090] 3CPP2F 5

[0091] 5CCP2F 5

[0092] 3CPtPET2 3

[0093] 3CC-P3F 5

[0094] 5CC-P3F 5

[0095] 2P-PN2F 2

[0096] 3P-PN2F 5

[0097] 1-4bP-PN2F 5

[0098] 5CPN2F 11

[0099] The proportion of various liquid crystal compounds in the bottle of TN first minimal mixed liquid crystal formula is: 33% of type I liquid crystal compounds, 11% of type II liquid crystal compounds, 43% of type III liquid crystal compounds, and 13% of type IV liquid crystal compounds. Weigh each liquid crystal compound according to the proportion of the formula, heat and stir to dissolve into a fluid state after weighing, vacuumize nitrogen replacement to maintain a vacuum of 100Pa, heat to a clear point, naturally cool to room temperature while stirring, and filter. Filtered TN f...

Embodiment 4

[0127] Compound Percentage / %

[0128] 2P-PN2F 1

[0129] 3P-PN2F 2

[0130] 5P-PN2F 2

[0131] 5CPN2F 7

[0132] 3CPET2 10

[0133] 5CP2F 3

[0134] 3CC4 5

[0135] 3CC5 5

[0136] 2CCP2F 9

[0137] 3CCP2F 13

[0138] 5CCP2F 13

[0139] 3CCePF 8

[0140] 4CCePF6

[0141] 5CCePF 10

[0142] 3CCPF 3

[0143] 3CCPET2 3

[0144] The proportion of various liquid crystal compounds in the bottle of TN first minimal mixed liquid crystal formula is: 12% of type I liquid crystal compound, 10% of type II liquid crystal compound, 78% of type III liquid crystal compound, and 0% of type IV liquid crystal compound. Weigh each liquid crystal compound according to the proportion of the formula, heat and stir to dissolve into a fluid state after weighing, vacuumize nitrogen replacement to maintain a vacuum of 2KPa, heat to a clear point, naturally cool to room temperature while stirring, and filter. The filtered TN first minimal nematic mixed liquid crystal, and then add the abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| isotropization temperature | aaaaa | aaaaa |

| isotropization temperature | aaaaa | aaaaa |

| isotropization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com