Centrifugally actuated govenor

A speed and motion technology, applied in the field of centrifugally actuated speed limiters, can solve the problems of poor material properties, difficult to buy, large tolerances, etc., to achieve the effect of magnetic field stabilization and elimination of manufacturing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

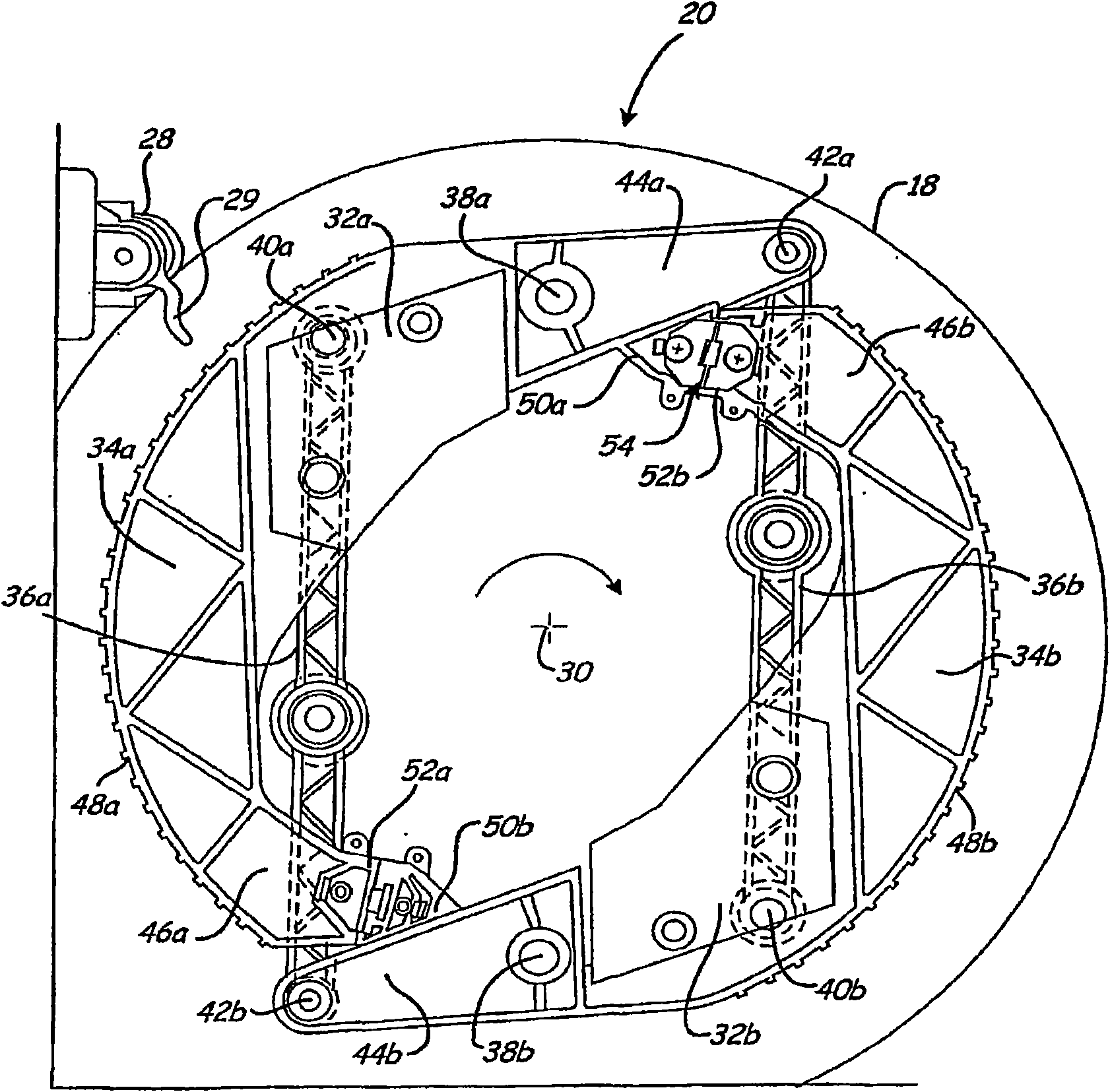

[0017] Wherever possible, the same or like reference numerals have been used for the same or like parts throughout the drawings.

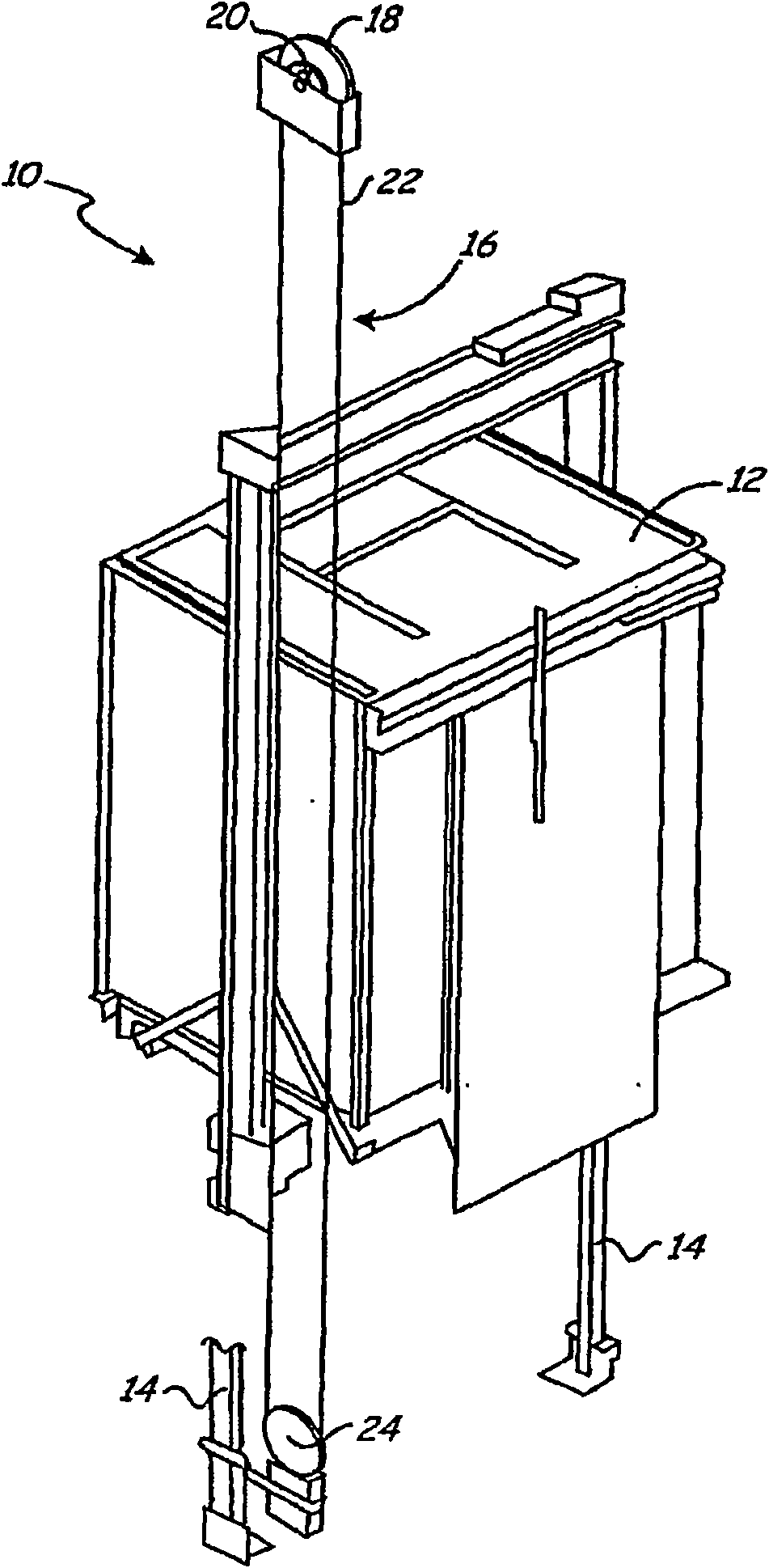

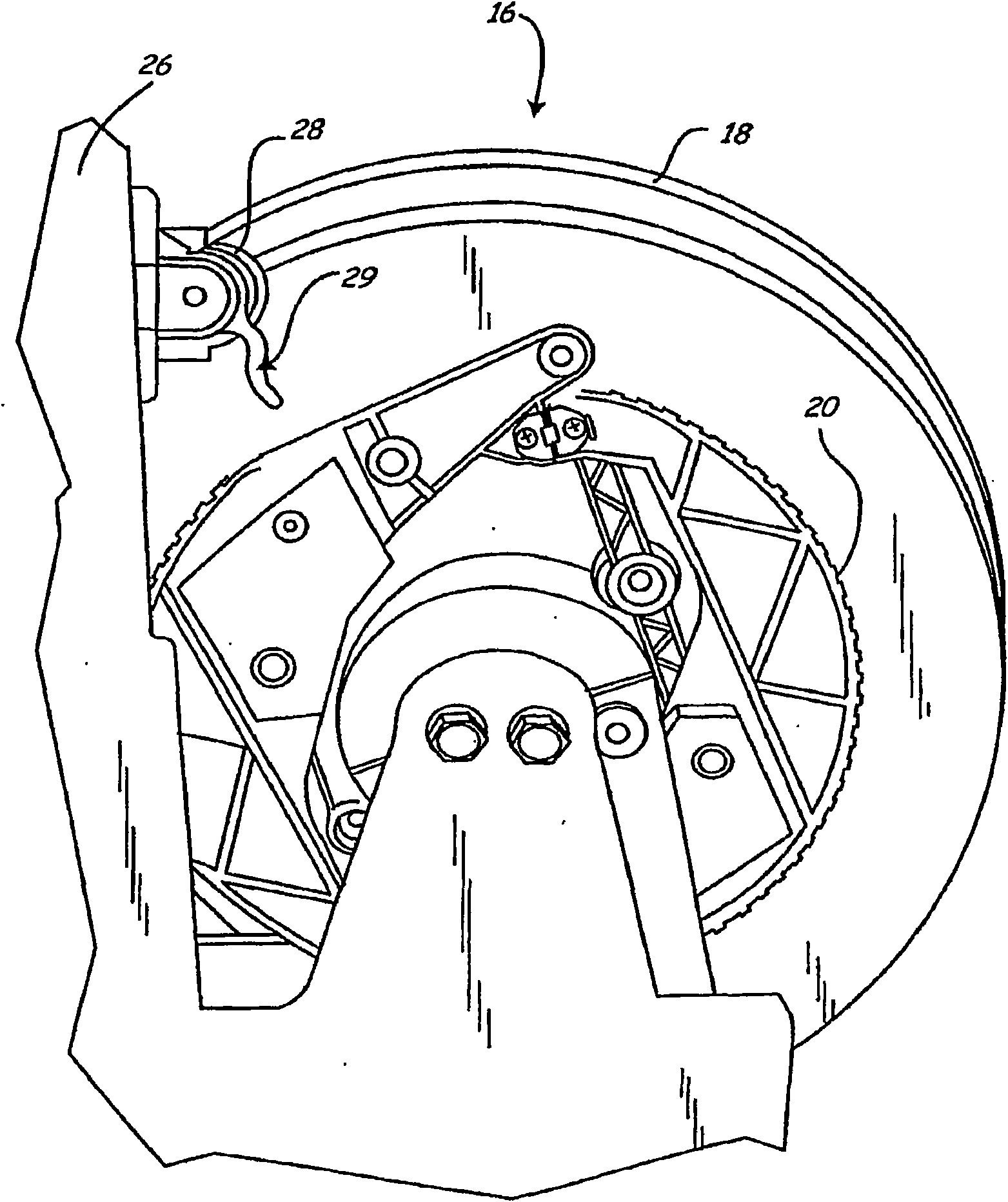

[0018] figure 1 Elevator system 10 is shown including elevator car 12 , guide rails 14 , and governor assembly 16 . The governor assembly 16 includes a trip sheave 18 , a governor 20 , a bead 22 and a tension sheave 24 . An elevator car 12 travels on or is slidably connected to guide rails 14 and travels inside a hoistway (not shown). The tripping sheave 18 and speed governor 20 are installed at the upper end of the hoistway in this embodiment. The loop 22 is wrapped partially around the trip sheave 18 and partially around the take-up sheave 24 (located at the bottom end of the hoistway in this embodiment). The rope loop 22 is also connected to the elevator car 12 , ensuring that the angular velocity of the tripping sheave 18 is related to the speed of the elevator car 12 .

[0019] In the elevator system 10 as shown, the speed governor assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com