Actuator

An actuator and action technology, applied in the direction of instruments, machines/engines, generators/motors, etc., can solve the problems such as the inability to fully correspond to the miniaturization and thinning of carrying, and achieve the improvement of life and energy efficiency, miniaturization, The effect of small energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

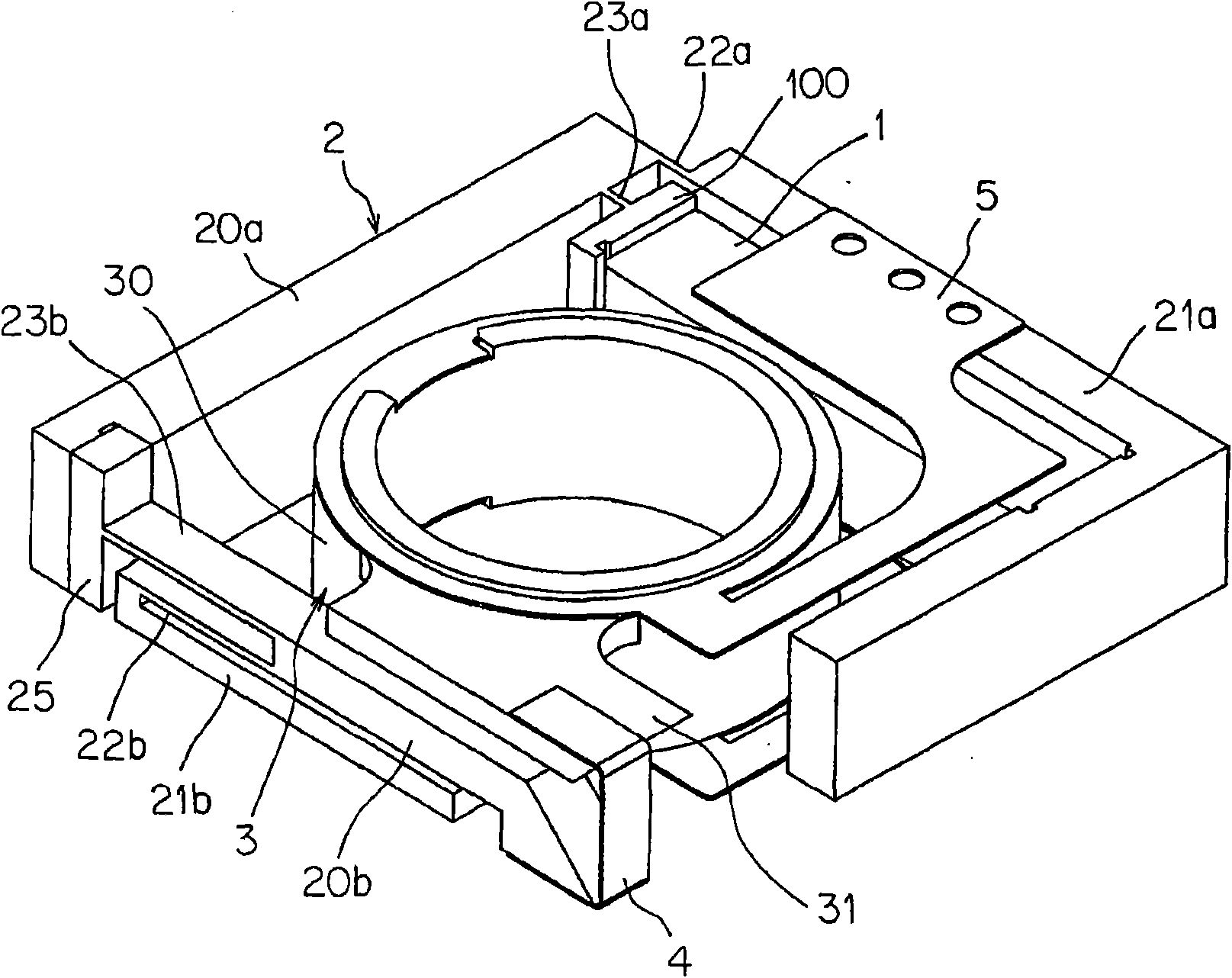

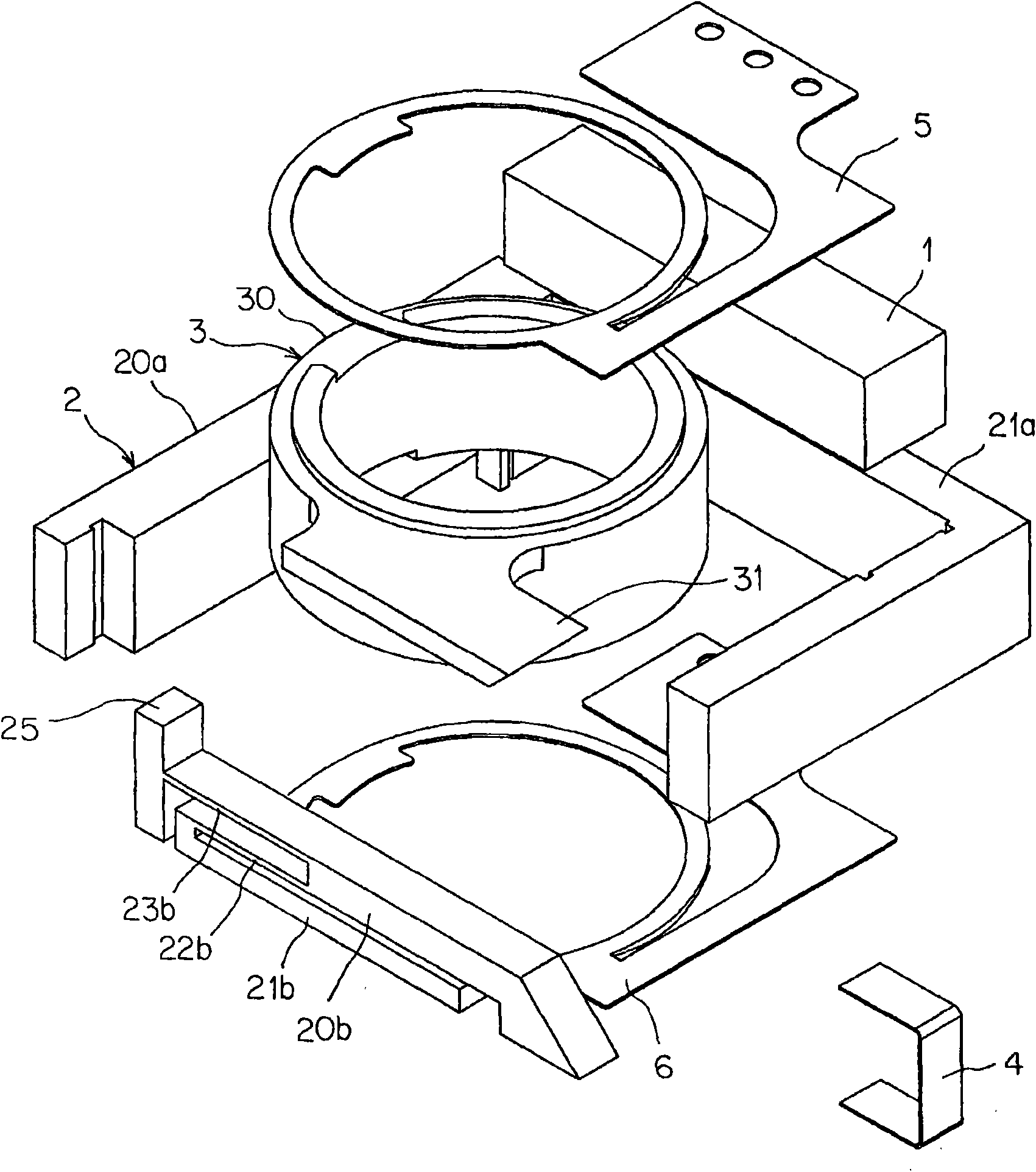

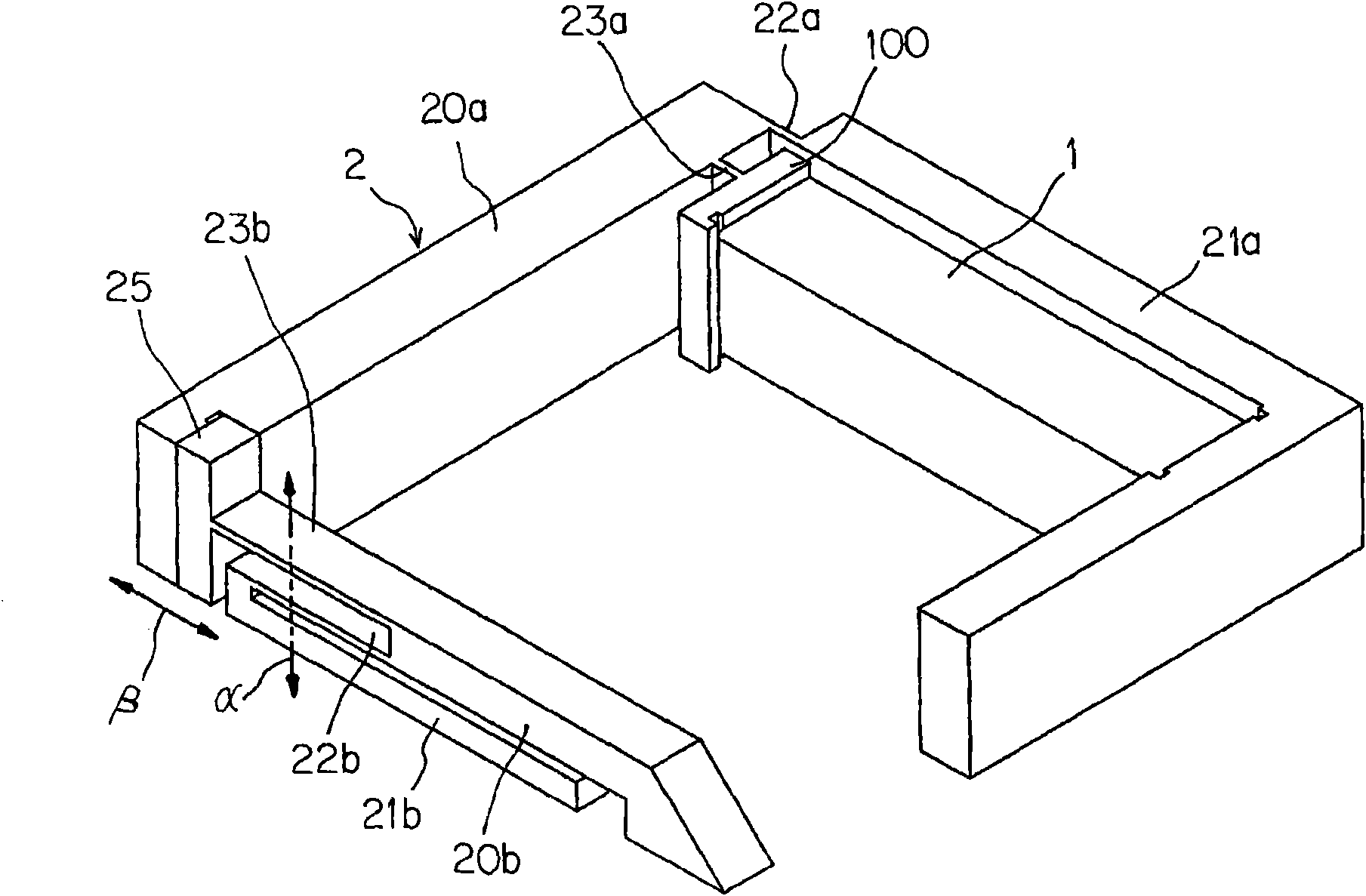

[0098] Figure 1 to Figure 5 One embodiment of the actuator of the present invention is shown, and a case where it is applied to a lens actuator incorporated in a lens module of a portable terminal is shown. figure 1 For the overall stereogram, figure 2 For the exploded stereogram, image 3 It is a perspective view showing a state in which movable parts are removed, Figure 4 For its top view, Figure 5 It is an explanatory diagram showing the function (operation method). In the figure, 3 is a movable member that is displaced by an actuator, which is a lens holder in this embodiment.

[0099] The actuator includes: a drive member 1 that deforms with a deformation amount corresponding to input energy and outputs the deformation as a displacement in a uniaxial direction; and amplifies the displacement output from the drive member 1 while amplifying the displacement The displacement amplifying mechanism 2 is transmitted to the above-mentioned movable member 3 to displace th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com