Rotary disc deep base point displacement meter and measuring method thereof

A technology of deep base point and displacement meter, which is applied in the direction of measuring devices, mechanical measuring devices, instruments, etc., can solve the problems of complex internal structure connection, low measurement accuracy of steel structure, and small displacement measurement range, so as to improve the upper limit of measurement and facilitate measurement , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

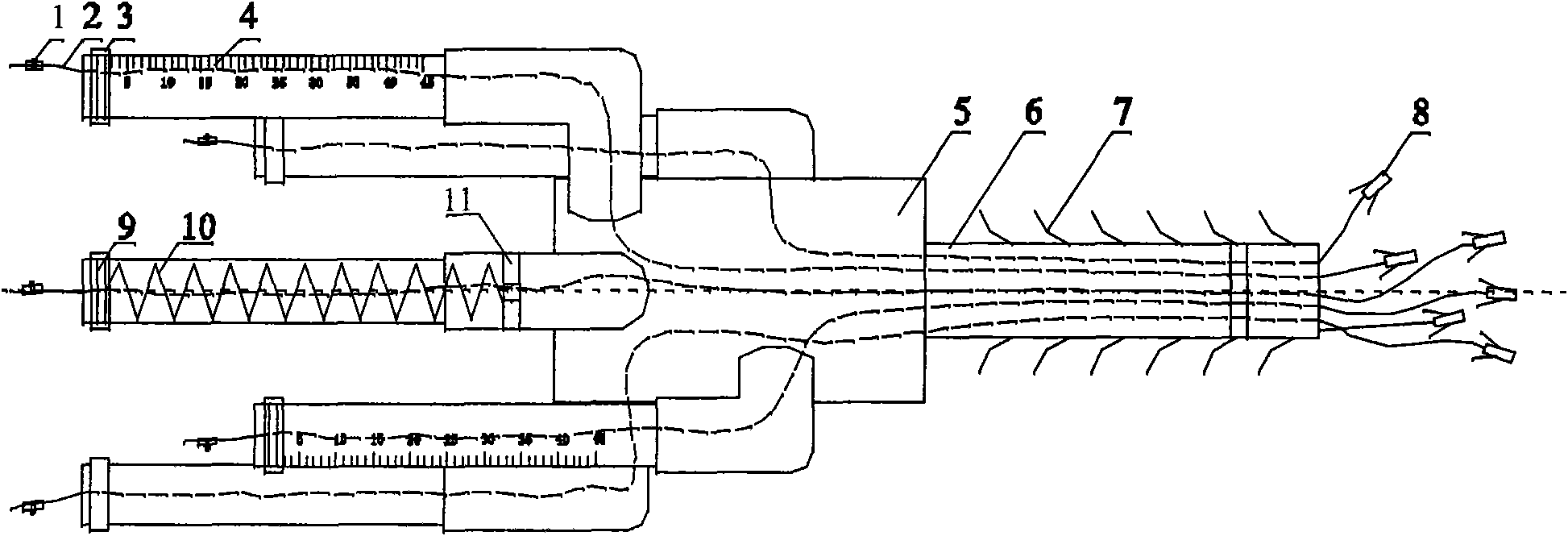

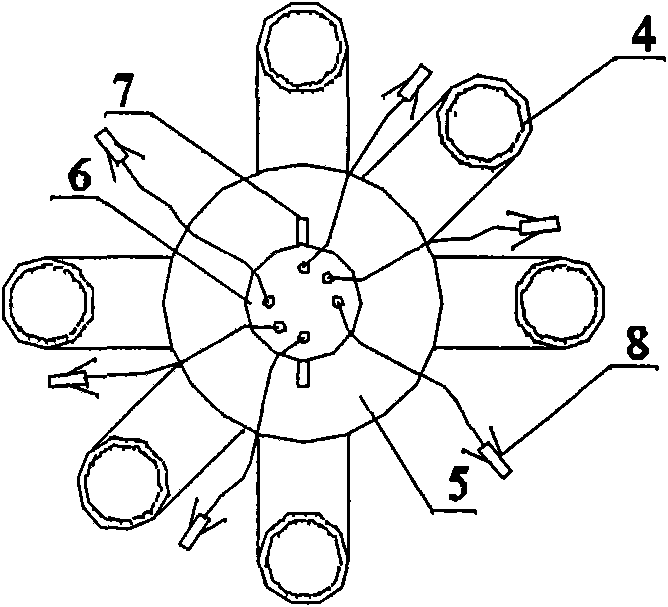

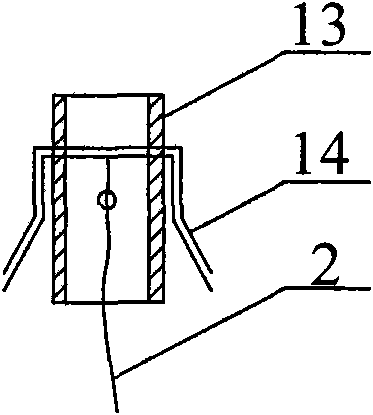

[0025] figure 1 figure 2 As shown, the turntable deep base point displacement gauge is mainly composed of a measuring cylinder 4, an orifice device 5, a fixer 6, a base point anchor head 8 and a measuring connection line 2. Measuring cylinders 4 are arranged in a circular shape with different lengths and scales are displayed on the outer surface. There are five or six measuring cylinders 4, and the length of each measuring cylinder 4 is set according to actual measurement requirements. One end of the six measuring cylinders 4 is respectively fixed on the casing of the orifice device 5, and its axis is parallel to the axis of the orifice device 5. A vernier slip ring 3 is installed on the measuring cylinder 4, and a stopper 9 and The retaining ring 11, the spring 10 is connected between the retaining block 9 and the retaining ring 11; the orifice device 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com